Outbound vs. Inbound Logistics + Why Outbound Is So Important in Modern Business

Logistics is a significant expense for any modern business, with logistics-related spending coming in at more than $1.64 trillion last year alone.

Depending on the size of your company and the price, size, and weight of your products, you could spend 11% of your sales revenue or more on warehousing and transportation.

But most companies simply regard it as “the cost of doing business.”

And that’s the wrong way to approach outbound logistics. It directly impacts the experience of every customer. By optimizing the process, you can not only reduce running logistics costs but transform a “business expense” into a reason to choose your company.

In this article, we’ll cover everything you need to know about outbound logistics and how to optimize your processes.

What we’ll cover:

- What Is Outbound Logistics?

- What is Inbound Logistics?

- What Is the Difference Between Inbound and Outbound Logistics?

- An Example of the Outbound Logistics Process

- Channels of Distribution

- Customer Experience Impact of Outbound Logistics & Delivery

- Real Business Benefits of an Optimized Outbound Logistics Process

- How OptimoRoute Improves Outbound Logistics

What Is Outbound Logistics?

Outbound logistics describes the process of storing, moving and distributing goods to deliver them to their final destination: the end customer. The stages of outbound logistics operations are warehousing and storage, distribution, transportation, and last-mile delivery.

Outbound logistics includes all systems that help prepare an order for delivery and get it to the end customer through delivery service.

Let’s take a more in-depth look at the individual areas of outbound logistics:

1. Warehousing and storage

To meet demand as you make continued sales, you need to keep a surplus of products in storage. In January 2020, US companies had, on average, a ratio of 1.39 inventory to monthly sales.

The goal of warehouse management is to keep products safe and readily available while awaiting purchase. You can store products in your own warehouse or one that is owned by a third-party logistics provider. Businesses commonly use warehouse management systems to handle many of the tasks involved with warehousing.

2. Inventory management

Inventory management involves picking, packing, and storing your goods in the right place. Many warehouses have inventory management systems to help with this.

3. Transportation

Next, is the process of shipping products to distribution or fulfillment centers. At this stage, transportation is typically done by big trucks/planes/freights. The long distances and large volumes can be a challenge, and following distribution center best practices is also key to ensuring efficient transportation of goods.

4. Last mile delivery

Last mile delivery is the most important step, and is also the most expensive. This is when your order goes from the distribution center to your customer’s door. This task is typically handled by a large fleet of smaller trucks or vans.

If you sell using the direct to consumer model, for example, from an e-commerce store or catalog, you need to cover these four stages effectively.

From managing the product in your warehouse to preparing the parcel and passing it on to a freight service, and delivering the final goods, every stage impacts whether the order gets to the customer’s door on time.

Just think of everything that happens behind the scenes so Amazon can offer same-day delivery from online sales.

What is Inbound Logistics?

Inbound logistics refers to processes and systems that bring goods and materials from a manufacturer or distributor to a business. This can include purchasing raw materials for production, finished products from manufacturers, or goods like packaging materials. Inbound logistics also entails the process of receiving these goods, checking them into inventory, and ensuring that they are safely stored.

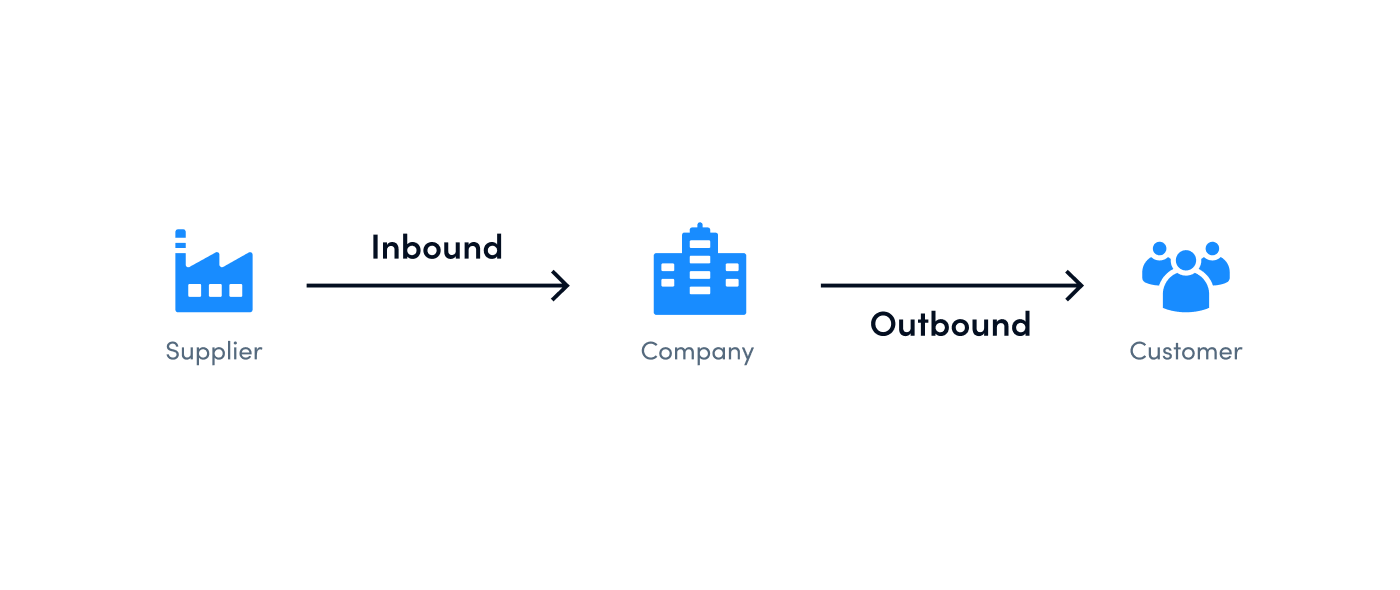

What Is the Difference Between Inbound vs. Outbound Logistics?

Both inbound and outbound logistics describe the movement of goods, the key difference between them is simple: inbound logistics encompasses all processes related to receiving your products from suppliers and manufacturers — incoming goods. It includes procurement and handling of raw materials, sourcing, buying, storing, and distributing goods, and supplier returns (reverse logistics).

On the other hand, outbound logistics is all about delivering products to customers or end users — orders going out. It includes inventory management, order management, packing, distribution, and more.

Together, outbound and inbound comprise your overall supply chain management strategy.

An Outbound Logistics Example

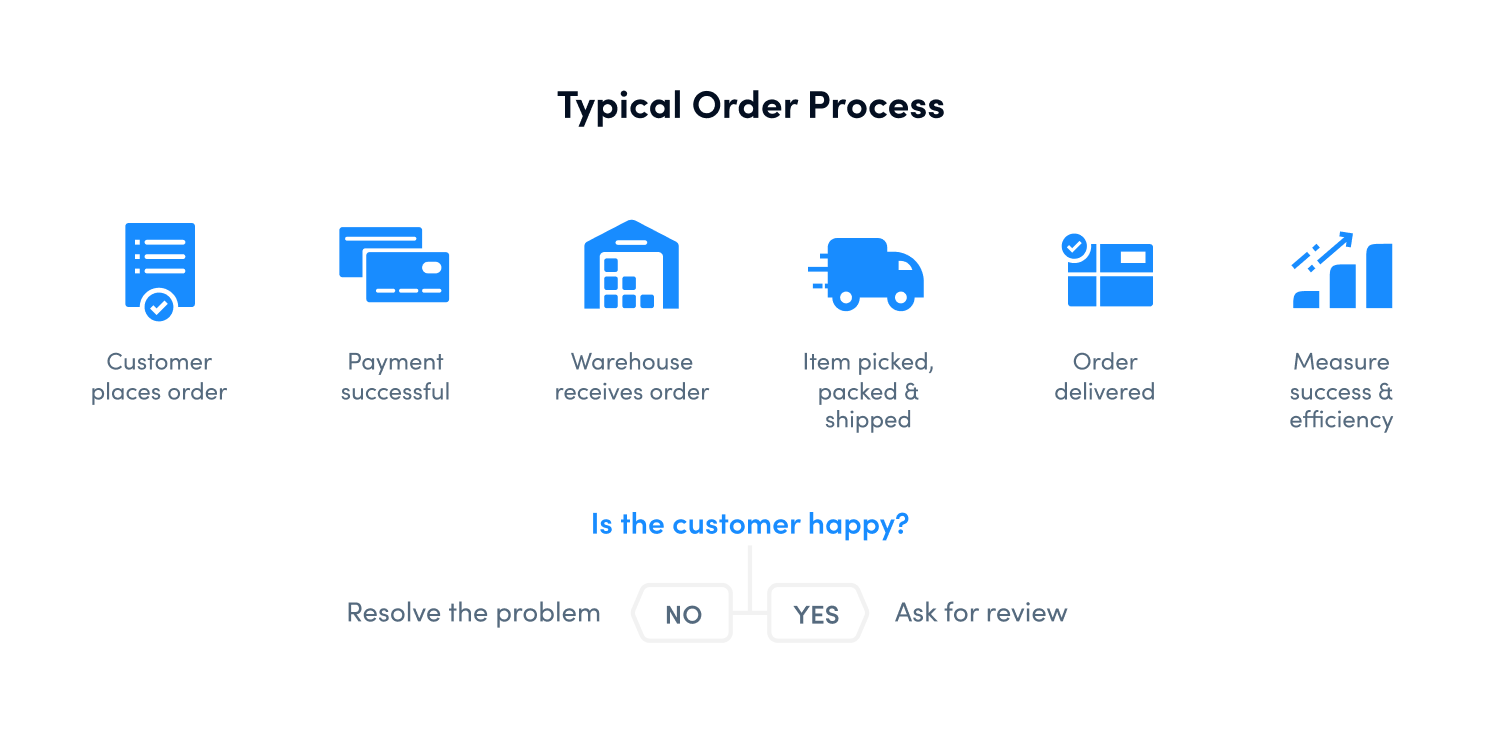

In this section, we will cover an example of an outbound logistics order process.

Let’s examine every stage for an e-commerce company that sells consumer products.

1. Customer places order

The customer places an order for a specific product on your e-commerce site or through your catalog.

2. Order is confirmed, and products picked in the warehouse

The warehouse confirms the ordered products, the workers pick the relevant inventory. If in place, the WMS system adjusts product counts based on the product id or stock-keeping unit (SKU).

3. Order is packed at warehouse

Workers in the warehouse pack the products and prepare them for shipping by moving them to the loading dock.

4. Trucks pick up daily orders

Freight trucks pick up the orders bound for the relevant distribution centers every day.

5. Trucks drive to distribution centers

The trucks drop off the ordered inventory at the closest distribution center to the customer.

6. Delivery drivers pick up orders at distribution centers

Delivery drivers pick up individual orders at distribution centers for their delivery area.

7. The package is delivered to the customer

The package arrives at the doorstep of the customer, completing the logistics process.

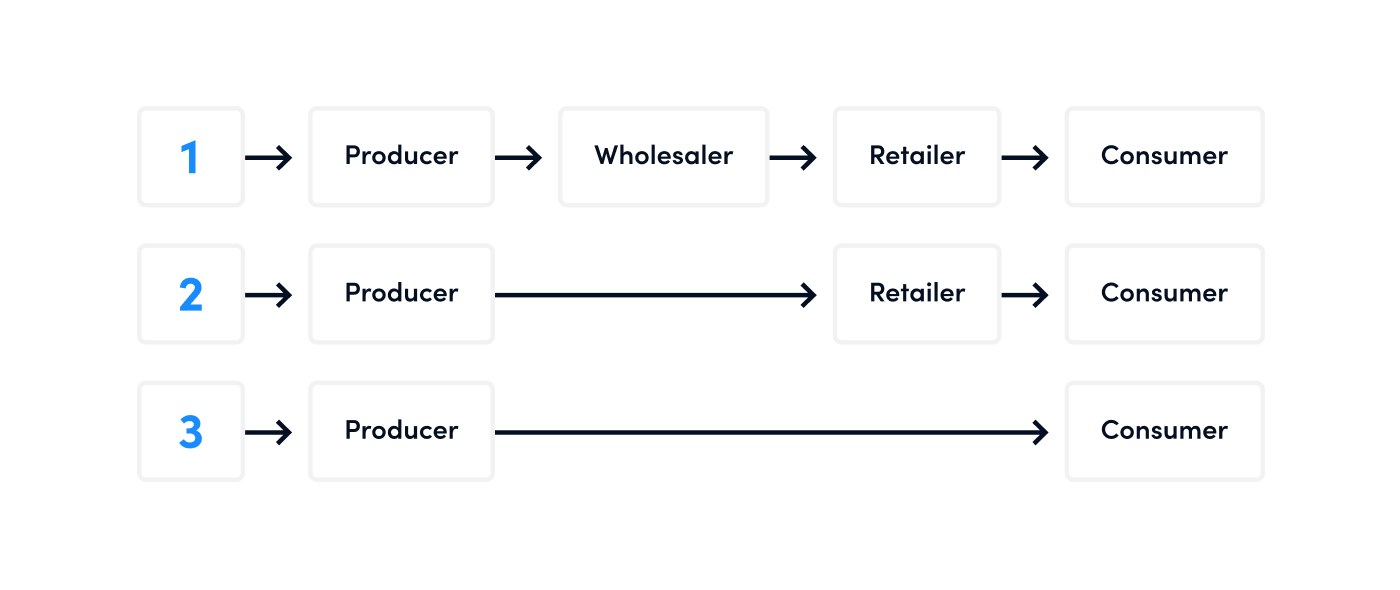

Channels of Distribution

Businesses that don’t sell straight to consumers, don’t handle the entire outbound logistics chain.

If your main distribution channel is a wholesaler or online retailer that fulfills orders, like Amazon FBA, it’s a different story. Your main concern isn’t optimizing each stage of the process. You need to pick reliable wholesalers, distributors, or retailers and develop strong relationships with them.

Work closely with supply-chain partners

The tail end of supply-chain management is a critical part of your outbound logistics. So if you don’t handle everything yourself, make sure you work closely with retailers or third-party distributors.

An excellent example of collaboration is P&G and Walmart’s supply-chain partnership. They share data and coordinate real-time adjustments to meet the changing demands of the consumer goods market.

A good way to kickstart a partnership can be to coordinate advertising efforts. If you show an interest in improving the bottom line for your retailers or wholesalers, they’ll be more interested in your products.

Outbound Logistics and Delivery Directly Impacts the Customer Experience

It doesn’t matter if you sell consumer products or customized solutions for businesses. Outbound logistics plays a big part in customer satisfaction for manufacturers or online retailers.

And 81% of companies single out customer experience as a competitive advantage.

Below, we’ve listed the top three criteria for meeting customer expectations and keeping them happy.

These three areas are essential to meeting and exceeding customer expectations and ensuring return business in the long term.

1. On-time delivery is essential

It’s 2020. With Amazon leading the pack with same-day delivery, you can no longer afford delayed shipments and packages.

Every hour your package is delayed is another burden on the customer relationship. To succeed in e-commerce, it’s not enough to promise fast delivery, you must keep that promise.

2. Delivering to the wrong address is unacceptable

What’s worse than getting a package late? Not getting the package at all because it was mishandled and sent to the wrong place.

3. The product must arrive in an acceptable condition

If the product is delivered on time, but it’s in an unusable or severely damaged condition, your customer won’t be happy. It’s an even worse experience than a delayed delivery.

If you use a third-party logistics provider, you must pick a trustworthy one.

Real Business Benefits of an Optimized Outbound Logistics Process

Optimizing your outbound logistics and delivery process isn’t just about making the customer marginally happier — it provides significant cost savings and has a real, tangible impact on your company’s bottom line.

Faster deliveries

63% of online shoppers now expect three-day shipping for domestic shipments. Being able to meet this expectation is a requirement for doing business online in 2020.

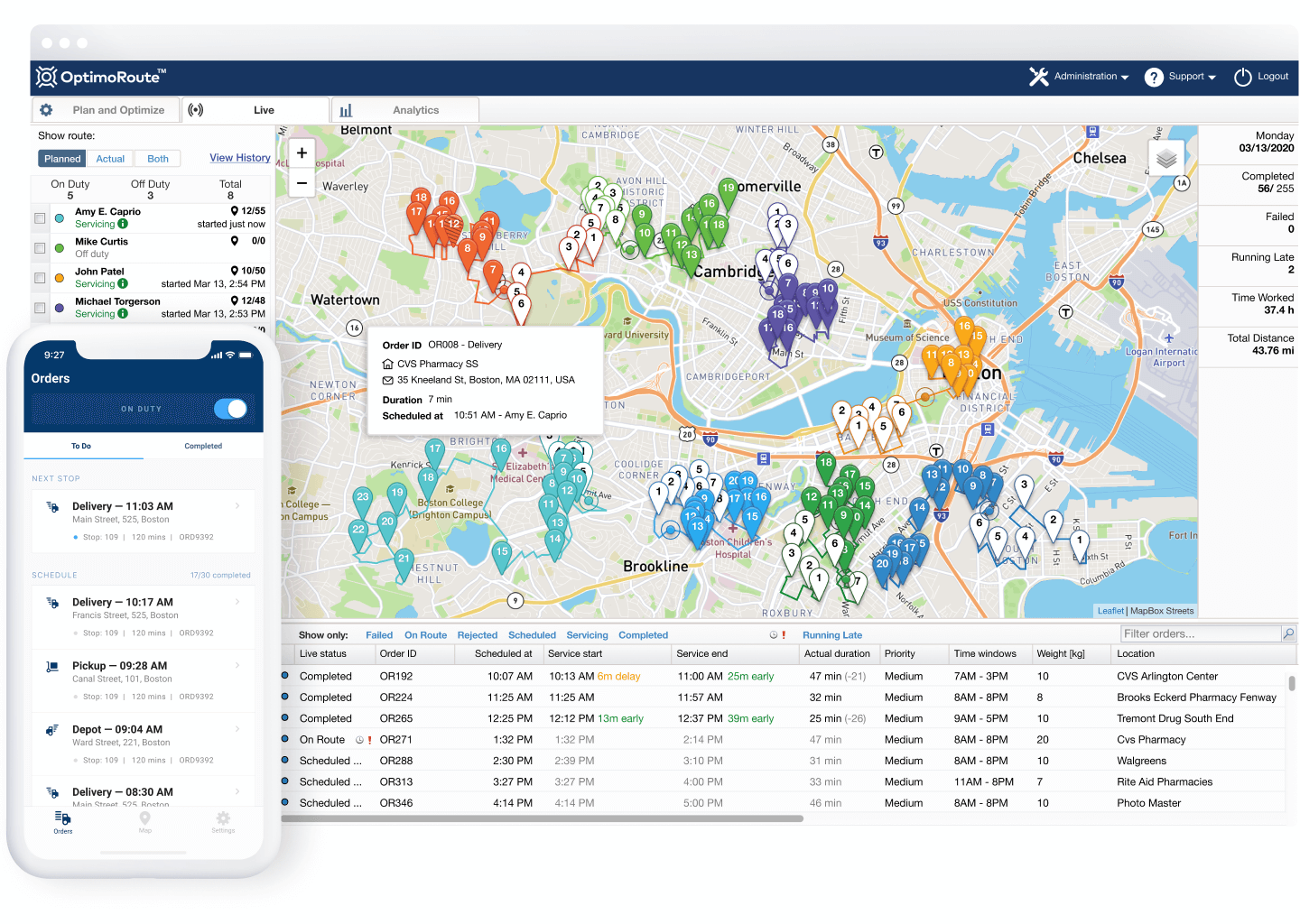

With OptimoRoute, you can easily plan the fastest, most efficient route for all your delivery drivers. Our planning tools consider all factors, including location, vehicle capacity and capabilities like refrigeration, which improves load planning and significantly speeds up your last mile delivery.

More on-time deliveries

With OptimoRoute as part of your logistics process, it’s easy to account for real-world challenges. Our software considers all factors, such as driving times, time windows, business hours, high priority orders, wages, vehicle capacity, driver start and endpoints, and more, when calculating routes.

Switching to OptimoRoute helped Hardie’s Fresh Foods improve their on-time delivery rate by 5% in a few months from 89% to 94%, with a 1.5% MoM improvement rate.

Fewer canceled orders and failed deliveries

Using OptimoRoute, in addition to your inventory management software, increases shipping accuracy. It’s easier for your team to ensure each load ends up in the appropriate delivery truck.

Also, our routes factor in time windows and ensure that deliveries are made when customers are actually at home.

Last-minute schedule changes from customers can complicate a plan/route, but OptimoRoute automatically recalculates routes and schedules on the fly.

Reduce your operational costs by 30%

Increase delivery capacity by 43%

Plan 7x faster

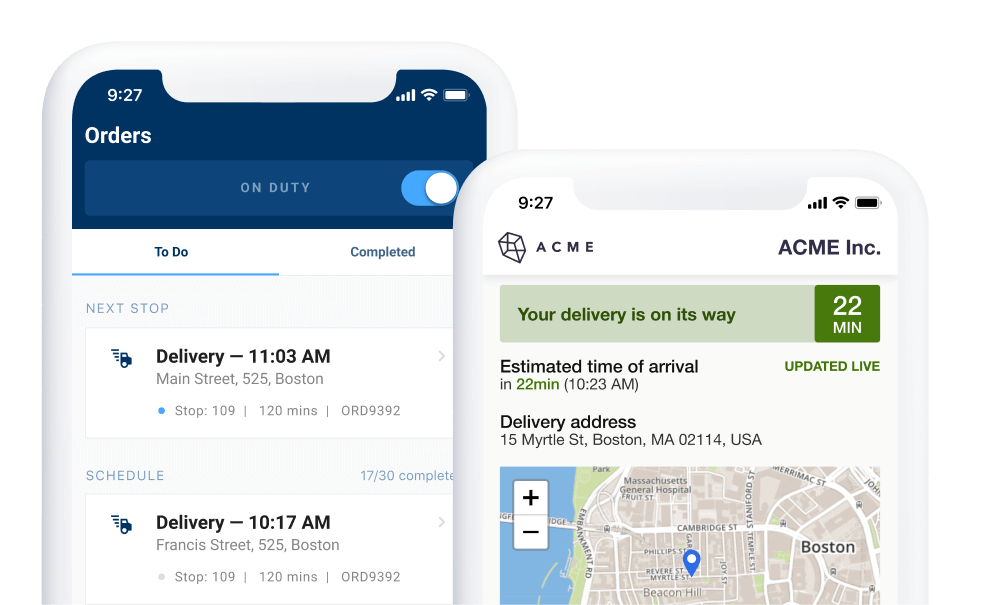

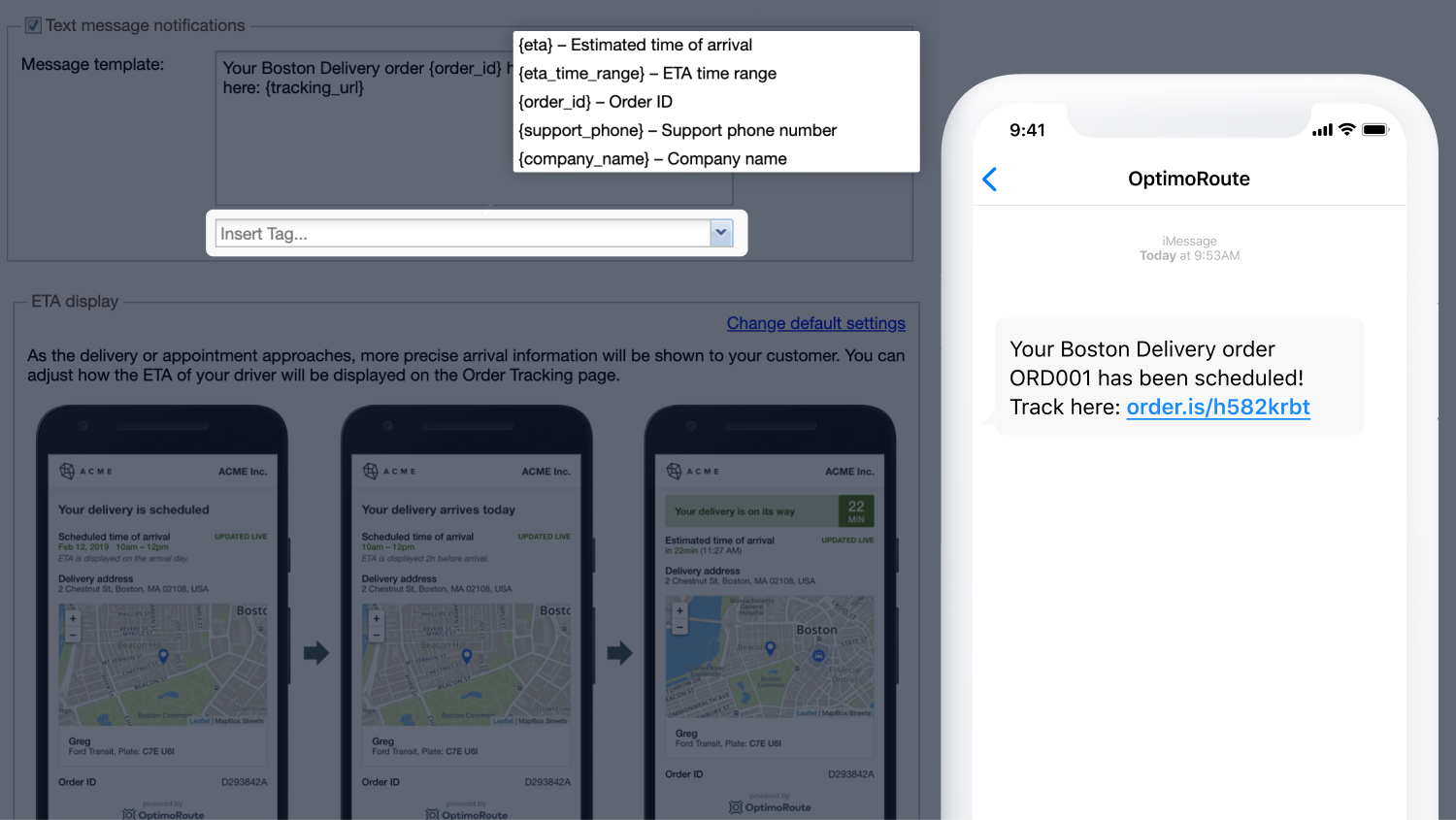

Realtime Order Tracking keeps customers in the loop

Modern consumers aren’t content with vague ETAs. They want real-time data that tells them where their order is right now.

With OptimoRoute, you get access to our Live ETAs as a standout feature. The real-time location data helps increase loyalty and satisfaction, and drastically reduces the number of ‘Where is my package?’ customer support inquiries.

Happier customers = more repeat purchases and increased brand loyalty

With more deliveries on, or ahead of, time, packages in better condition, and fewer canceled orders, your customers will be happier.

Loyal customers are willing to spend up to 36% more with a brand and are much more likely to make repeat purchases.

Furthermore, route optimization also drives down fuel costs and boosts the sustainability of your business, making it a key plank of an overall green logistics strategy that can help further drive brand loyalty.

How OptimoRoute Improves Outbound Logistics

The foundation of a healthy logistics strategy is using the right tools. It will help you control every aspect of your distribution network.

OptimoRoute can help you gain the edge in your market with better logistics management and route planning.

Smart route planning is up to 8 times faster

Whether you have 100 or 1000 orders, OptimoRoute schedules the best routes instantly. Your planning staff can focus on high-level decisions instead of doing hours of manual routing.

After switching to OptimoRoute, Hardie’s planned 8 times faster, with a 60% reduction in required working hours for business operations.

Maximize the delivery capacity of your existing fleet

With our route optimization tools, your drivers will always follow the shortest, most efficient route.

Southern Star used OptimoRoute to increase their order capacity by 100% while keeping the same fleet and workforce. Automated, much faster planning, more efficient routes, and complex workflow support transformed the way they operated their business.

Easily supply multiple depots and distribution centers

Keeping the route between your customers and your stored products short is key to maintaining fast shipping times.

Using OptimoRoute, it’s effortless to plan deliveries and schedules with a different start and end point. That makes it easy to supply an extensive logistics network with a limited fleet of trucks or vans.

Realtime Order Tracking and notifications

If you want to minimize failed deliveries, your customers need to know precisely when your delivery drivers will arrive.

With real-time GPS delivery/package tracking and email and SMS notifications, customers can prepare and be ready at the time of delivery.

Ensure driver compliance

OptimoRoute’s advanced schedules include lunch and required driving breaks, making compliance easy and painless.

Improved mileage: less gas used per delivery

The shorter your route, the less gas and driving time your driver will use for each delivery. That’s one of the key benefits of using OptimoROute

With OptimoRoute’s route planning tools, Gallagher Pools and Spas, with only a fleet of 20 drivers, was able to reduce mileage by 8,000 miles every single month.

Better workloads for drivers

With less time on the road, you lower the overall payroll expenses, increase your revenue, and improve the workloads for your drivers.

But that’s not all.

OptimoRoute uses automated complex workload distribution features to help you reduce overtime and balance workloads evenly among your drivers.

Final Thoughts

If you settle for okay or “good enough,” logistics and order fulfillment will always remain an expense instead of a business asset.

Understanding your channels of distribution and every step of the process is a good start, but you won’t get far without the right tools. With OptimoRoute, you can completely transform your logistics process in many ways:

- Speed up your delivery times

- Improve your on-time delivery rate

- Save time on planning

- Maximize delivery capacity

- Minimize failed deliveries

- Better workloads for your drivers

If you’re ready to improve your OTD rates, lower your payroll, and improve the working lives of your drivers, take OptimoRoute for a free test drive today.

Try OptimoRoute™ for Free

No installation or credit card required