What Is Reverse Logistics? The Delivery Process You’re Overlooking

7 min read

If your business doesn’t have a great reverse logistics plan, you could be losing revenue and not even realizing it.

Planning for products to return to your company (returns management) may seem counter-intuitive. Still, for companies that offer rentals, product pick-ups, or any type of shipment logistics management, the path backward can be just as costly as the path forward. It might be time you take a closer look at your company’s reverse logistics system and make sure it’s working for you, not against you.

What Is Reverse Logistics?

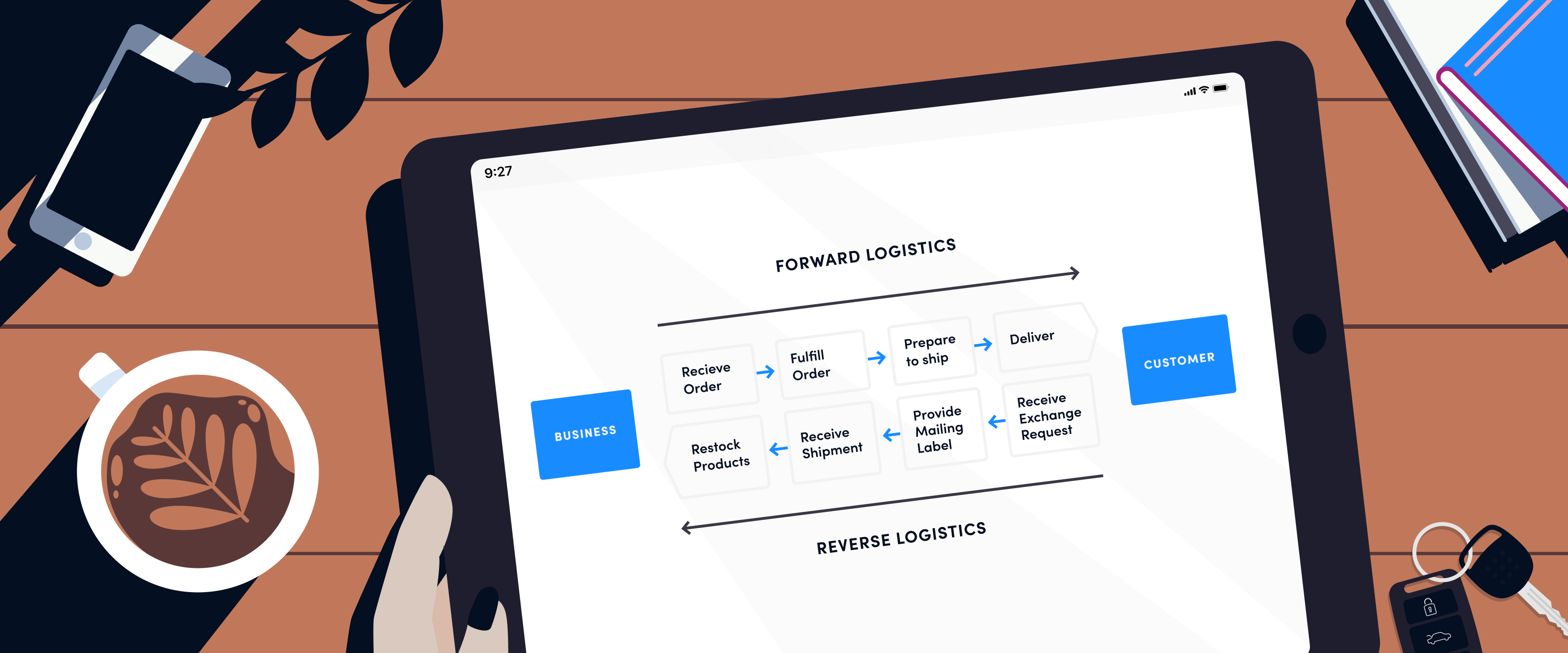

Reverse logistics is any part of the logistics process where goods or services move from what is typically their final destination (the customer) back to their origin (or in some cases, to a third location). Reverse logistics encompasses work that happens after a product is delivered to a customer.

Let’s say you run a craft brewery. Delivering kegs to restaurants would be part of your forward logistics process. Picking up empty kegs from restaurants and bringing them back to your brewery would be reverse logistics. Another example would be returned goods in ecommerce.

According to US NAVY Senior Chief Logistics Specialist (Submarines) Kelly Griffith, “Reverse logistics is absolutely critical” for business and operational success. He explains, “In the military, reverse logistics is acutely critical because no matter how much planning you do ahead of time, things change rapidly in the field. Target locations change, situations change, and you have to be able to adapt quickly.”

On the civilian side, Sr. Chief Griffith is a business management specialist for the United States Department of the Interior. He told us that, “In business, reverse logistics can set you up for long-term success and increase the lifetime value of a customer. Just look at car companies. How many parts in your vehicle need to be serviced by a mechanic that’s certified by the manufacturer? When you buy a new car, the dealer doesn’t just send you on your way. You walk out the door with a plan in place outlining when you’ll need to bring that vehicle back for service at multiple intervals.”

How reverse logistics fits into your logistics chain

The precise steps in a reverse logistics chain vary from business to business, but reverse logistics typically refers to any part of a logistics supply chain that flows from the customer back to your business (or sometimes, to a third location). For a product company, this could be your customer exchange or returns process. For logistics services that offer to dispose of expired products for their customers, this could be taking containers to a recycling center.

It’s easy to see how forward logistics equates to revenue. After all, the goal for most businesses is to make money by selling a product or service to customers, not taking it back. Forward logistics includes manufacturing products, delivering them, and all of the steps you need to take to get your product into a customer’s hands.

Reverse logistics operations do not directly correlate to revenue for many businesses, which is why they are often overlooked. But improving your reverse logistics process can help you build a loyal customer base. Just consider how important a seamless return process is. In a survey conducted by Invesp, 92% of e-commerce shoppers said they would buy from a company again if the product return process were easy. Your relationship with your customer doesn’t end at delivery. It goes much further.

4 Common Reverse Logistics Examples—and the Benefits You Could Be Missing Out on

Even if you’re not using reverse logistics on a day-to-day basis, you’re likely to need it at some point. The following examples illustrate just a few ways specific types of companies can benefit from excellent reverse logistics.

1. Pick-up and delivery services

Businesses that offer pick-up and delivery services rely heavily on reverse logistics. For a dry-cleaning and laundry service, reverse logistics includes picking up dirty linens and transporting them to the business location to be cleaned. Full-service laundry businesses need to plan pick-up routes in addition to planning delivery routes.

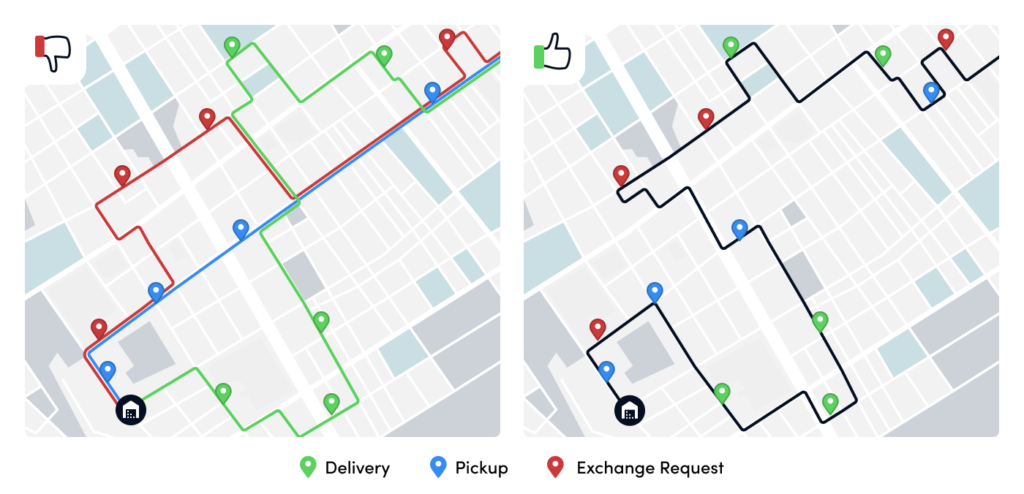

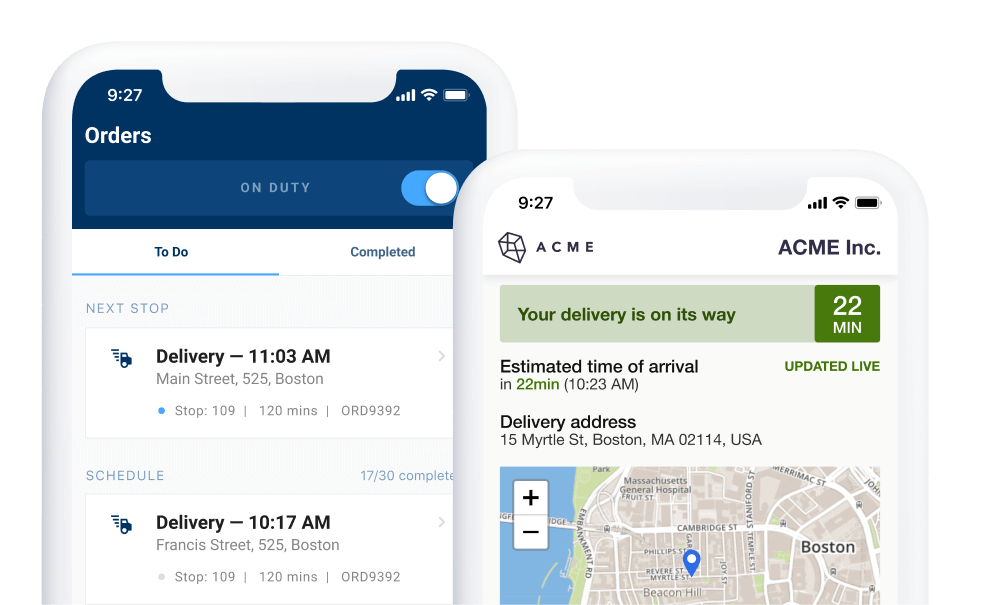

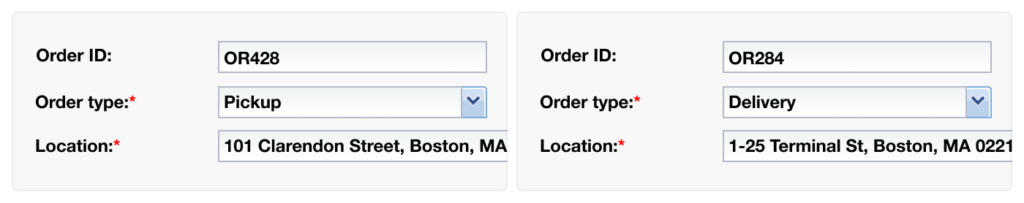

Reverse logistics can be used here to schedule pick-ups around already-planned delivery routes, thereby increasing revenue without even needing to hire additional drivers. Using laundry and dry cleaning route optimization software such as OptimoRoute, you can combine your pick-up and delivery planning quickly and efficiently while creating a better workload balance for drivers. With OptimoRoute, delivery managers can plan both pick-up and delivery routes in a fraction of the time.

One of the greatest reverse logistics examples in this sector is Oberweis Dairy, which has been in business since 1930. To this day, Oberweis offers fresh milk delivery to their customers, and they use reverse logistics to pick up their iconic glass bottles when customers are ready for a refill.

Reduce your operational costs by 30%

Increase delivery capacity by 43%

Plan 7x faster

2. Rental returns

Businesses that rent out specialized tools, heavy machinery, or film equipment can benefit significantly from effective reverse logistics. Streamlining the process of recollecting assets at the end of a rental is vital for these types of business. The reverse logistics process needs to include picking up assets, inspecting rented gear for damage and ordering any necessary repairs or maintenance, cleaning, and eventually restocking so they can be rented out again. Fortunately, since rental companies know when the rental period ends, they can plan pick-ups and allot time for cleaning and maintenance in advance.

Rental businesses can use reverse logistics planning to minimize downtime for equipment cleaning and repairs. Shortening the amount of time equipment is out of commission will increase sales and customer satisfaction, too, because it means assets will be ready to be rented out again faster. Finally, great reverse logistics can minimize stress on equipment managers and give them more time to focus on strategy.

3. Returns and exchanges

Sometimes, for any number of reasons, a customer will need to return or exchange an item. Return rates vary by niche or industry, and for some businesses returns are very common. When this happens, product companies must have an efficient reverse logistics plan in place for handling the returned product. Without it, you won’t be able to deliver great customer support, and the customer experience will be damaged.

In a survey conducted by Zendesk and Dimensional Research®, 97% of the 1,044 individuals surveyed said that bad customer service affected their buying behavior. On the flip side, 87% said good customer service affected their buying behavior. Customers appreciate businesses that help them when they need it and make returns and exchanges as easy as possible. Considering reverse logistics when writing your return policies helps customer service representatives know exactly what to do when something doesn’t go quite as planned. Being prepared will pay off by boosting your customer loyalty and satisfaction.

4. Large appliance or furniture removal

Retailers that sell large products like refrigerators or sofas can use reverse logistics to set themselves apart by offering to remove a customer’s old appliance or furniture. Some buyers won’t be able to dispose of the old appliance or furniture on their own. Hiring another company to come in and take away the old item adds another step to the process and can often be very expensive. By offering a solution to this problem, you can make your business stand out and increase customer satisfaction.

The best part is that, since you’re already delivering a large item, you won’t need to schedule another truck or workers for pick-up. You can simply pick up the old item while you deliver the new one to your customer. Plus, you’ll be able to seamlessly integrate pick-ups into delivery schedules with the right route optimization software.

How to Improve or Expand Your Reverse Logistics With OptimoRoute

Optimizing your reverse logistics can increase your bottom line, improve efficiency, and retain customers. Here are just a few of the many ways OptimoRoute can help.

Improve supply chain management

OptimoRoute enables dispatchers and fleet managers to easily prioritize important pickups and drop-offs, optimize and combine pickup and drop-off routes for efficiency, and balance driver workloads. As a result, your supply chain becomes more efficient from end-to-end.

Optimize cargo space

OptimoRoute can factor in the size and weight of items being picked up and dropped off to match them with drivers based on the capacity of individual vehicles in your fleet. This feature improves the cost-effectiveness of your efforts by working to reduce the need for drivers to make multiple trips, cutting down on fuel costs, and increasing the number of stops each driver can make during a single shift.

Expand remanufacturing and refurbishment services

Refurbishing or remanufacturing parts is common in the automotive and tech industries, but this process can benefit other types of businesses as well. Damaged or defective products could still have usable parts, and reverse logistics can help you capitalize on that potential. Instead of having a customer keep or throw out an imperfect product, you can expand your returns management process and get those sub-optimal parts back to be reallocated. OptimoRoute makes it easy to start, improve, or expand upon your existing reverse logistics program by seamlessly combining it with your forward logistics program.

Minimize environmental impact through proper disposal

Consumers care about the environmental impact of their purchases. In a survey of 6,000 consumers conducted by Accenture, 83% of respondents said that they “believe it’s important or extremely important for companies to design products that are meant to be reused or recycled.” Also, 72% said that compared to five years ago, they are now purchasing more environmentally friendly products.

A great way to attract more customers and build brand recognition is to take care of proper disposal of large appliances or handle end-of-life logistics in a way that reduces environmental impact. CLEAResult, the largest North American provider of energy-efficient solutions for utilities, businesses, and consumers, does this through their appliance-recycling initiative.

CLEAResult uses OptimoRoute to orchestrate the pick-up and recycling of thousands of old appliances each month in the state of Michigan. They’re using highly efficient reverse logistics to make a positive impact on the planet, provide a valuable service to customers, and build brand loyalty.

How Do You Manage Reverse Logistics?

Having the right software is key to implementing a sound reverse logistics strategy—whether you’re managing reverse or forward logistics. We’ve even put together a list of the top reverse logistics providers out there. OptimoRoute is here to help with your reverse supply chain, last-mile delivery, and much more. Start your free 30-day trial today, and see what highly efficient reverse logistics can do for your business.

Try OptimoRoute™ for Free

No installation or credit card required