Logistics Strategy 101 + 3 Lessons From Amazon

Source: Amazon

In February 2021, Jeff Bezos, founder and CEO of Amazon.com, announced that he would be stepping down as the company’s CEO. During his tenure, Bezos built Amazon into a global e-commerce behemoth.

A major part of Amazon’s success? Its robust logistics strategy. Amazon standardized delivery programs like free two-day shipping and free one-day shipping, and it has been able to deliver at these fast service levels around the world.

By studying Amazon’s logistics strategy, businesses small and large can shape successful logistics strategies of their own. In this article, we’ll break down how to develop a logistics strategy with examples from Amazon and three logistics strategy lessons from Amazon that you can apply to your business.

Jump ahead to any of the topics covered in the article:

- What Is a Logistics Strategy?

- How Do You Develop a Logistics Strategy?

- Three Logistics Strategy Lessons From Amazon

- Design Your Logistics Strategy by Working Backwards

What Is a Logistics Strategy?

A logistics strategy specifies how businesses manage their supply chain and delivery operations so that they can maintain a competitive advantage in their industry.

Logistics strategies often take the form of one-page documents that guide decision-making by clearly Logistics strategies often take the form of one-page documents that clearly communicate the competitive priorities, scope, and geography that a company chooses to focus on with its inbound and outbound logistics operations..

How Do You Develop a Logistics Strategy?

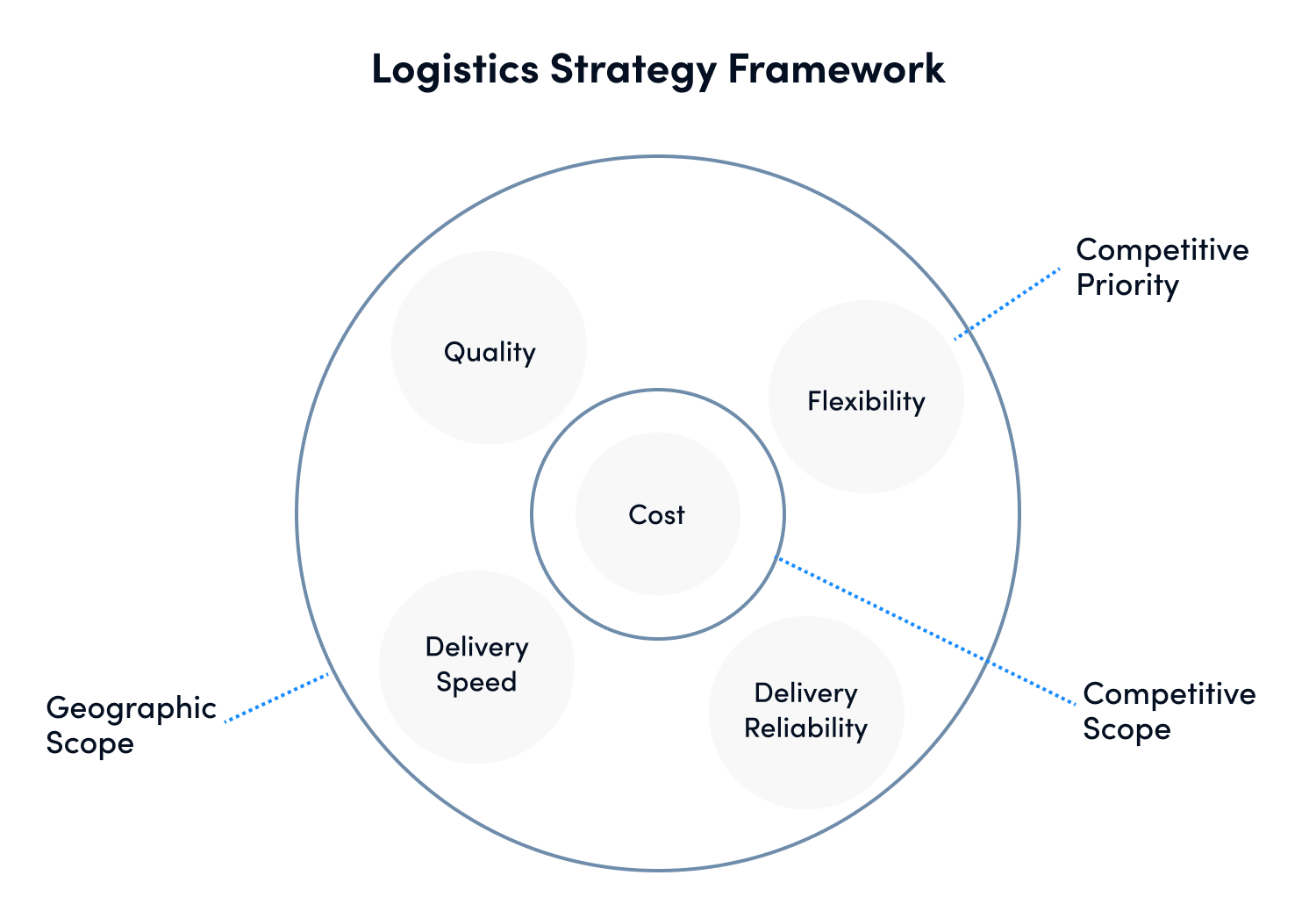

To explain how to build a logistics strategy, we’ll be using a framework designed by Gregory Neal Stock, Noel Greis, and John D. Kasarda. This methodology was developed in 1999 and continues to be cited by experts in the supply chain and logistics field.

Stock, Greis, and Kasarda argue that strategic planning for logistics management requires focusing on three strategic dimensions: competitive priorities, competitive scope, and geographic scope.

1. Identify your competitive priorities

Competitive priorities are areas of your supply chain you choose to focus on to help stand out to your customers. Some examples of competitive priorities you may choose to focus your initiatives on are:

- Cost: Lowering the costs of your logistics system can improve your bottom line and overall business profitability, allowing you to reinvest in other areas of your business. When you make your logistics more cost-effective, you can also reduce your shipping prices to your customers.

- Quality: Having a high-quality logistics operation can increase your customer satisfaction. One way to boost quality is to invest in customer-centric logistics tools like OptimoRoute, so you have detailed visibility into shipment statuses including Realtime Order Tracking, Live ETA and Proof of Delivery.

- Flexibility: A flexible logistics operation allows you to make rapid design changes in your operational design and/or adapt to swings in customer demand easily.

- Delivery Speed: If your logistics operation can remove inefficiencies and deliver your products to your customers at service levels that are faster than your competitors, they’re more likely to order from you again.

- Delivery Reliability: In a world where free two-day shipping is standard practice, on-time delivery is table stakes for retaining customers.

- Sustainability: Implementing a green logistics strategy that reduces fuel costs and waste is a high priority for many businesses in 2021.

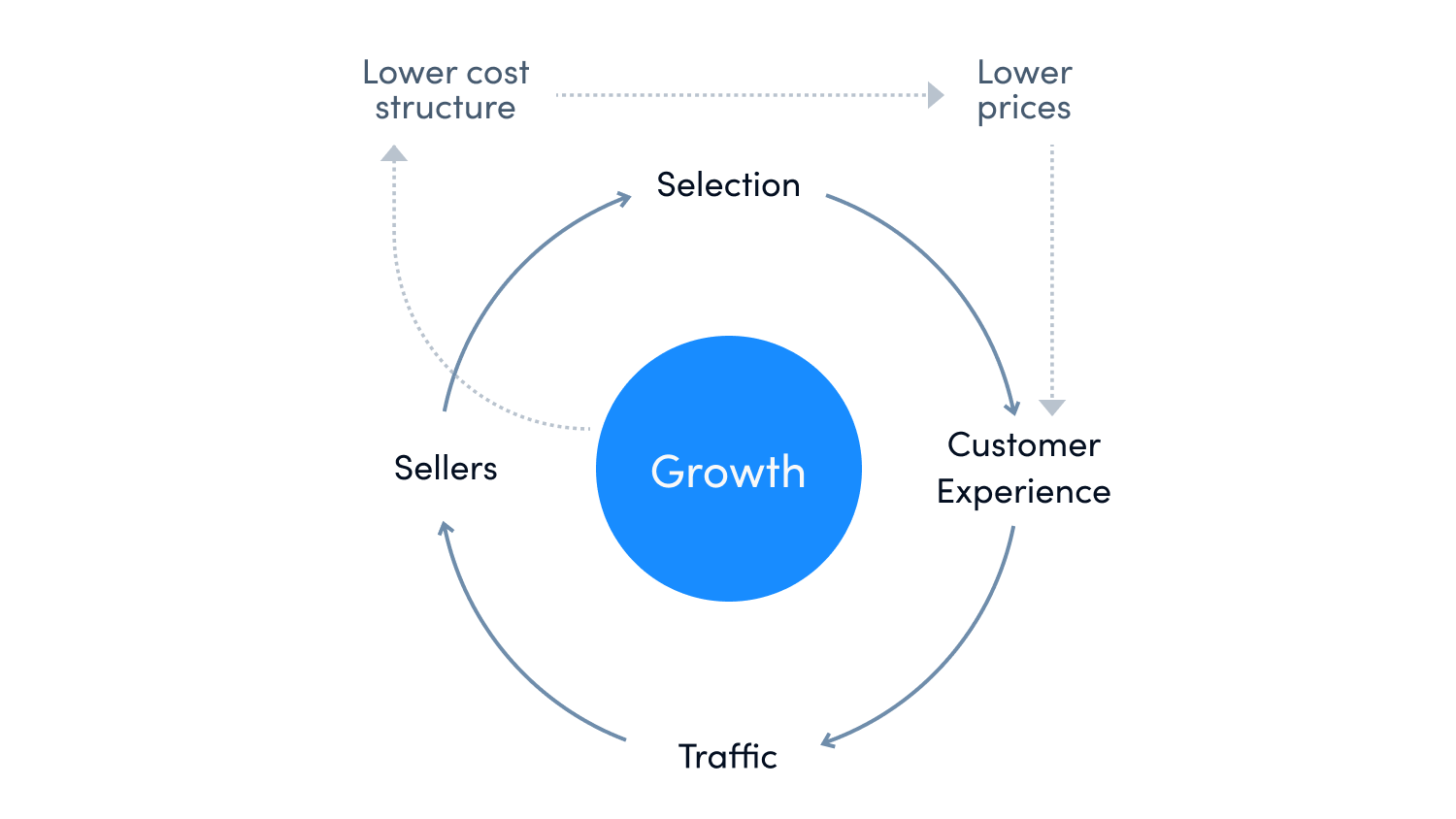

Amazon’s competitive priorities were determined by the “Amazon flywheel,” developed by the company in 2001. It has guided Amazon’s business strategy over the years. In 2017, the company acknowledged its influence on its supply chain strategy at an industry conference.

As we can see in this image, lower costs lead to lower prices, which in turn incentivizes more customers to come to their site. More site traffic leads to more sellers joining the platform. This increases product selection on the site, which drives more sales and revenue for the company, which enables them to further reduce their costs and grow even more.

From this framework, we can pull three competitive priorities for Amazon—growth, cost, and customer experience––since those are the priorities the company has the most control over in the flywheel.

2. Identify your competitive scope

Competitive scope refers to how many competitive priorities you choose to tackle simultaneously.

Early on, Amazon seemed to be prioritizing growth by partnering with shippers like Fed Ex and UPS instead of handling deliveries in-house. The company faced a setback in 2013 with delivery delays from these 3PL service providers during the holiday rush.

In response, it chose to prioritize customer experience—measured by delivery speed and reliability metrics—by bringing more of its logistics functions in-house rather than outsourcing to a logistics provider. In order to balance their costs when they made this change, they adopted a contractor delivery model instead of hiring their delivery personnel. This decision led to the creation of Flex, Amazon’s contractor delivery program, launched in 2015.

When you first design your logistics strategy, it may make sense to focus on one competitive priority. As your operations scale and your business grows, you’ll have different competitive priorities that you’ll need to focus on. You can then shift your competitive scope accordingly, just like Amazon did.

3. Design your geographic scope

Geographic scope refers to the number of markets you choose to serve.

As of 2018, Amazon is available in 50+ countries. But it has had to adjust its geographic scope in response to local competition. In 2019, it closed Amazon China after facing stiff competition from Chinese competitors Alibaba and JD.com.

Depending on the size of your business, you might have a small geographic scope. It might just be neighborhoods that you deliver to. But even in the early stages, it’s worth keeping in mind how your geographical scope might expand as you tweak your logistics strategy over time.

Three Logistics Strategy Lessons From Amazon

Amazon designed its logistics strategy to be a competitive differentiator and a source of customer experience innovation. With these lessons, you’ll be able to do the same for your business.

Turn your logistics strategy into a competitive advantage

With Amazon’s launch of free two-day shipping with Amazon Prime in 2005, it created a competitive moat with its logistics operations.

Before Amazon Prime, two-day shipping was a premium purchase for customers. Prime forced retailers to make two-day shipping a commodity that their customers expected from them.

Amazon expanded its moat in 2006 with Fulfillment by Amazon (FBA). With FBA, businesses could market and sell their products to customers, and Amazon would pick up, store, and deliver them from their distribution centers. FBA products expanded the catalog of available products that Prime members could purchase.

What are some ways you can turn your logistics strategy into a competitive advantage?

- Offer free shipping to your customers if your competitors aren’t already offering it to encourage customers to place more orders with you.

- Promise delivery in shorter timeframes. For example, if you’re delivering food, offering deliveries in 30 minutes or less could help you stand out to your customers if your industry isn’t used to such fast turnaround times.

Offer tailored incentives to reduce heavy shipping volumes

Amazon offers multiple shipping options and incentives to customers who choose one delivery day over another.

When customers choose No-Rush Shipping at checkout instead of One-Day or Two-Day Shipping, they can earn promotional rewards.

Another example is “Amazon Day,” where customers can combine multiple deliveries so that they arrive on one day of the week instead of different days. By doing so, customers can reduce the number of boxes that Amazon uses to deliver their items.

Both No-Rush Shipping and Amazon Day are incentives that Amazon offers customers to optimize its logistics operations. With these programs, it avoids having to deal with heavy delivery volumes every day of the week, which also reduces chances to miss customer expectations.

How can you use tailored incentives in your logistics operations?

- Offer discounted shipping for specific time frames. Give your customers the option to choose a shipping window from multiple options at checkout. Offer discounts for shipping windows that work better for your logistics plans.

- Offer rewards for a future purchase. Another incentive you can provide at checkout is a reward or a coupon credit when customers choose a specific shipping window. You can adopt this tactic to incentivize your customers to order their deliveries in windows where you have lower volumes. This can increase your delivery densities and streamline your last mile unit economics.

Focus on relevant competitive priorities as you scale

Amazon focused on different competitive priorities with its logistics strategy at different phases of its journey.

The company prioritized convenience and delivery speed for its customers after it brought more of its delivery operations in-house after 2013. However, that convenience came with a cost. Porch piracy became a regular occurrence for customers who frequently ordered from Amazon.

Amazon responded by focusing on security as a competitive priority with Key by Amazon. When customers enroll in the Key by Amazon program, they can choose to have their Amazon packages delivered in their garages, in their cars, or in their businesses. It launched Amazon Key in 2017 and expanded the program to 4,000 cities in the US in 2020.

At OptimoRoute, we’ve proactively addressed the porch piracy problem with our Proof of Delivery feature.

With Proof of Delivery, your delivery drivers can collect your customer’s signature, take photos, or provide written notes when they’ve completed a delivery. You can then choose to share this information with your customers by sending them a text or an email with a link to the proof provided by your driver.

Design Your Logistics Strategy by Working Backwards

Amazon believes in “working backwards” when it designs its product and operations strategies. Teams in the company start product development by writing a press release before the product has even been designed.

This strategy of starting at the launch and working your way backwards can be applied to your logistics strategy, too. Think about what you want your customers to experience at the end of your logistics process. Work in reverse from there to identify your competitive priorities, your competitive scope, and your geographic scope, and you’ll be poised for long-term success.

Try OptimoRoute™ for Free

No installation or credit card required