Using OptimoRoute, Hardie’s Fresh Foods Reduces Mileage by 20% While Increasing Delivery Capacity by 14%

5 min read

FOOD DELIVERY, NORTH AMERICA

Hardie’s Fresh Foods is a major Texan food distributor of produce and other fresh food products. Its 160 trucks make thousands of deliveries every day, all over the state.

Competing in a fast-paced and low-margin industry, Hardie’s implemented OptimoRoute to reduce operational costs, increase capacity, and make planning and deliveries more efficient. By using OptimoRoute:

- Mileage across the entire fleet is down 20%

- Delivery capacity increased 14% – with driver costs decreasing by 12%

- Planning is 8x faster and involves 60% less manpower

- The on-time delivery (OTD) rate has gone from 89% to 94% and is rising 1.5% MoM

Hardie’s also wanted better insights into how it could maximize the use of its resources, including the ability to perform projections of new workflows with increased order volumes:

- A 12% decrease in driver costs coupled with a 14% increase in delivery capacity can be achieved

- An advanced modeling tool for accurate simulations, to assess the impact of adding new customers.

“Rather than bringing in another software service, I like being able to do it all – planning, projections, simulations – through OptimoRoute. It’s much simpler that way, for me and my staff, and we just trust OptimoRoute to give us reliable results every time.”

Mileage reduced by 20% and 8x faster planning

Capacity gains of 14% and driver-related costs down 12%

Better customer service: OTD from 89% to 94% and increasing 1.5% every month

Powerful modeling tool: To confidently commit to the service requirements of new customers

Reduce your operational costs by 30%

Increase delivery capacity by 43%

Plan 7x faster

About Hardie’s

When Hardie’s says “we’ve got Texas covered”, it’s not kidding. One of the premier fresh food distributors in the southwest, Hardie’s prides itself on connecting chefs to the farm: delivering locally-sourced produce and products to schools, restaurants, and grocery stores. From the Red River to the Rio Grande, Hardie’s makes over 8,000 deliveries a week to 2,400 customers – and is growing.

Hardie’s has been a family-owned business for three generations – but everything about its operations is large-scale. Its three distribution centers in Houston, Dallas and Austin have more than 163,000 square feet of refrigerated warehouse space (almost the size of 3 football fields). In one year, Hardie’s delivers 10 million packages and covers 4.6 million delivery miles.

The Food Distribution Industry Is Low-Margin. To Compete, Hardie’s Needed to up Its Game

As soon as logistics manager Arley Garner took over the transportation side of the business two years ago, he realized that Hardie’s needed to modernize the way it ran its complex, large-scale food distribution operation:

The 3 key things we were looking for were a reduction in miles, in trucks, and higher performance on our deliveries.

Garner envisioned a more competitive, flexible and growth-oriented Hardie’s. To achieve this the business desperately needed a faster route planning system that used minimal manpower to produce completely optimized routes. It had to be a system with workflow simulation tools. And finally, it had to be able to integrate with Produce Pro, its ERP system.

However, Garner knew that humans alone wouldn’t be capable of making the necessary changes. Sophisticated and powerful software technology was the solution, it was just a matter of finding the right product for its specific workflow. After months of benchmarking against other solutions, OptimoRoute was a clear winner. It proved that it could handle the Hardie’s workflow while achieving better savings and efficiency gains than other solutions, and seamless integration with Produce Pro was possible.

Immediate Efficiency Gains: Lower Mileage, Improved OTD, Quicker Planning

As soon as it implemented OptimoRoute, Hardie’s started seeing improvements in day-to-day operations, proving that the route optimization software was capable of achieving the initial goals Hardie’s had set. The impressive efficiency gains are occurring in various areas of operations:

Mileage is down 20%

OptimoRoute replaces static planning, giving Hardie’s optimized routes that would not be possible to create without sophisticated route optimization software. The efficient routes reduce mileage by 20% across the entire fleet – cutting thousands of miles and effectively saving thousands of dollars a day.

While Hardie’s used static planning, Garner explains that adding new customers based on a dispatcher’s knowledge of the area was precarious and didn’t take into account all the variables – increasing inefficiency on the road tremendously:

Customers would just get added to routes – so our guys were driving back and forth, from one end of town to the other end of town, over and over again.

Reducing mileage is a major benefit for businesses in the food distribution industry. It’s one of the areas that can realistically be controlled by a business, greatly contributing to its ability to keep costs down.

Improved OTD and accurate on-location time modeling

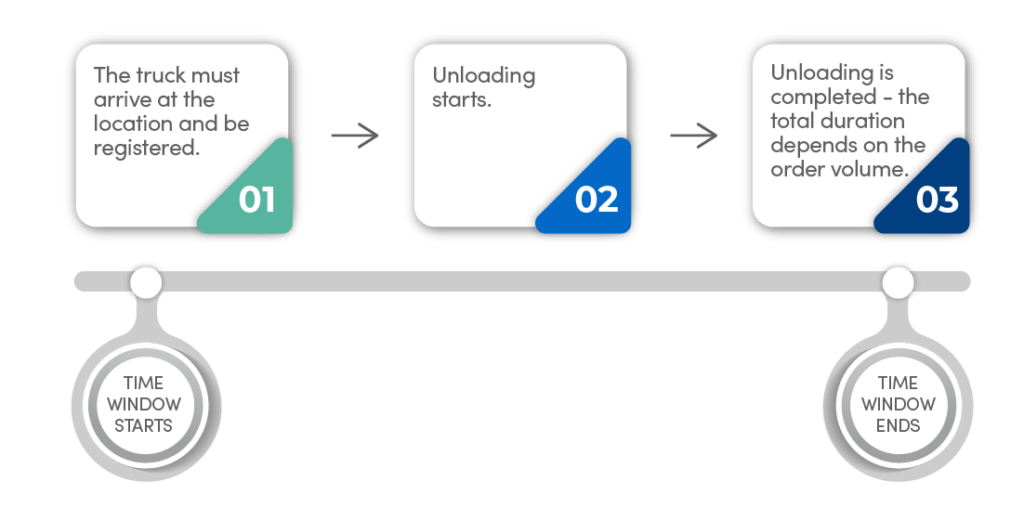

On-time delivery (OTD) is one of the most important performance indicators in the food distribution industry, directly affecting the ability to retain customers in the long run. Almost all customers have strict time-windows for receiving deliveries. However, OptimoRoute recognizes that the delivery process is actually made up of three stages – and all of them must take place within the predefined time window:

OptimoRoute’s robust design fully supports this specific workflow because the calculation of total order duration is automated, giving Hardie’s the flexibility to optimize schedules accordingly. Garner illustrates this with a simple example:

One of our customers expects a delivery of 30 crates, and the software knows that we need 10 seconds to unload each crate. So based on this, we get an accurate total order duration of 20 minutes – making sure we get everything done within that customer’s time window.

Hardie’s daily delivery schedules are planned according to accurate order durations, reducing the flow-on effect of deliveries going longer than expected. The ability to account for these real-world constraints has improved Hardie’s OTD at a rate of 1.5% MoM:

With OptimoRoute, our on-delivery rate is above 90%, and we’re confident it will reach 98% or 100% as soon as drivers adapt to the new system.

8x faster planning, 60% fewer people involved.

Daily planning for thousands of deliveries takes place at the three Hardie’s distribution centers in Austin, Houston and Dallas. With OptimoRoute:

- Planning manpower has gone down 60%. Each city only needs 1 transportation route coordinator – compared to the 2 or 3 people per distribution center that used to perform static planning.

- Planning is 8 times faster. Each coordinator spends a maximum of 2 hours planning the following day’s routes, instead of the hours and hours of tedious static planning.

Garner shares the example of how the Houston coordinator plans over 700 orders every day:

Before, planners would have to work constantly to get orders routed. Now, one planner goes in, punches a couple of buttons and goes to lunch – and he’s done the planning for the next day!

Now Hardie’s Knows Where It Can Make Even More Efficiency Gains

Garner explains that Hardie’s was looking for a route planning solution that offers even more than optimized everyday planning. Hardie’s wanted better quality insights into how it can best use its resources, to make data-driven decisions when it comes to resource allocation and distribution.

The ability to reduce the number of trucks used was crucial for Hardie’s – giving Garner complete flexibility when managing driver costs and vehicle costs:

Increasing delivery capacity was another goal. OptimoRoute gives Hardie’s this capability, enabling 14% more orders with the same number of trucks:

This is approximately two additional jobs per driver per day – or, more than 330 extra deliveries per day. It’s exceptional.

Garner knows that increased delivery capacity and reduced truck numbers provide Hardie’s a great deal of room to move. He values the detailed insights that OptimoRoute gives him, knowing he has the potential to continually improve the way that deliveries are assigned to its drivers. Overall, this puts the business in an excellent position to balance workloads and miles driven while always taking into consideration driver safety.

Hardie’s Uses OptimoRoute as a Powerful Projection Tool to Help Manage Its Future

Another area of business that Hardie’s relies on OptimoRoute is to model new workflows and delivery routes for prospective clients. Unlike its competitors, OptimoRoute is flexible enough to provide this function, indispensable to large, complex operations that want stable and controlled growth. ‘Sandboxing’ lets Hardie’s accurately simulate day-to-day operations that include the stops and timing constraints of a potential customer.

Hardie’s benefits from the ability to test new routes and experiment with increased workflows (virtually – rather than in the field with real orders). Thanks to OptimoRoute, the need for guesswork has been removed – because 160 trucks and thousands of fresh food orders out on the road every day mean that Hardie’s can’t afford to rely on chance and hope that newly added customers’ deliveries will be successfully completed.

Now, Garner can confidently commit to fulfilling the service requirements of prospective customers. Using OptimoRoute as a dependable modeling tool lets Hardie’s know in advance what the impact of increasing delivery volumes will be. It’s the power to shape its growth, which is especially valuable in the food distribution industry, where there are few aspects of operations that a business has control over.

Try OptimoRoute™ for Free

No installation or credit card required