Shipping and Delivery Accuracy: How to Minimize Errors and Maximize Revenue

7 min read

On-time, accurate delivery is a huge part of the customer experience for physical products purchased online.

In 2019, 84% of shoppers reported that they were unlikely to choose a brand again after a bad last mile delivery experience.

So improving your shipping accuracy is not only key to improving customer satisfaction, but also key to winning repeat business and business growth.

In this article, we’ll cover how you can tackle shipping errors and improve shipping accuracy by transforming and updating your warehousing and delivery operations.

To navigate to the section which interests you most, click below:

- What Is Shipping Accuracy?

- How Do You Measure Shipping Accuracy?

- Consequences of Inaccurate Shipping

- Causes of Inaccurate Shipping

- How to Make Your Shipments and Deliveries More Accurate

- How 2 Guys With Knives Optimized Their Shipping Accuracy With OptimoRoute

What Is Shipping Accuracy?

Shipping accuracy is the consistency between a customer’s order and what is delivered. Essentially, it means that an order’s exact quantity and SKU should match a customer invoice and that it gets delivered to the right address at the specified time.

Accurate fulfillment ensures that the customer gets exactly the product they ordered — the right make, model, and color — at the right time and to the right place.

How Do You Measure Shipping Accuracy?

Measuring the accuracy of your orders is quite simple: divide the number of accurate, timely delivered orders by the total number of orders shipped during a particular period (also known as a “cohort”).

While 100% accuracy might be impossible for a large-scale organization, every business should aim for 99% and above.

The only way to ensure consistently high rates of accuracy is to set in place systems and use software solutions to minimize human errors.

Consequences of Inaccurate Shipping

Even if you get it right most of the time, inaccurate shipping can have a considerable impact on your relationships with customers and your bottom line.

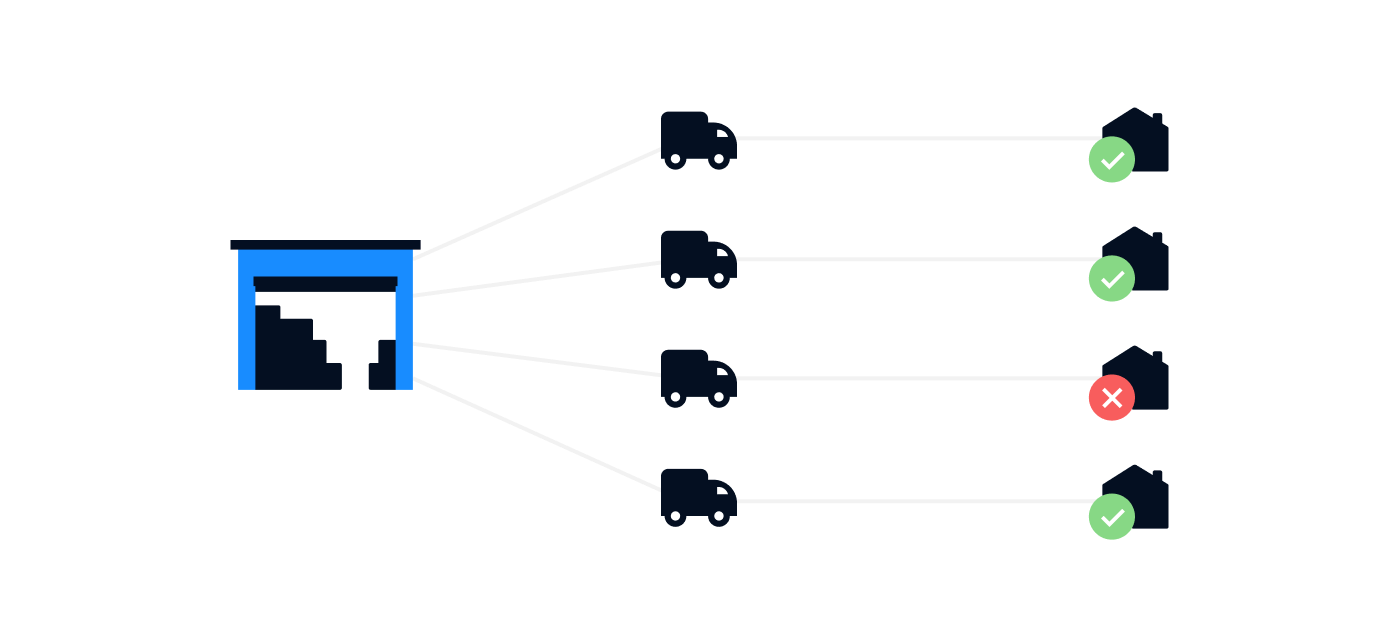

1. Failed deliveries equal extra fuel & driver payroll

Failed deliveries happen when there’s an inaccuracy in the shipping address, the delivery driver makes a human error, or the driver doesn’t make the required time window.

Every failed delivery results in the delivery driver having to return at a later time, which increases fuel costs and required working hours.

These unnecessary shipping costs add up to a lot of money. Failed deliveries cost UK retail businesses alone $2.08 billion every single year.

2. Product returns equal extra operational costs

If you send the wrong products, you don’t just manage to annoy your customers, you also incur a lot of additional operational costs. You have to receive and store the products all over again.

Your staff must also start from scratch with picking, packaging, and shipping the correct product.

And all the additional cost associated with that work comes (exclusively) out of your profit margin, as the customer has already paid (and won’t be paying twice for the additional work).

3. Chargebacks

In the event of shipping items to the wrong address, customers might initiate chargebacks, leading to loss of revenue, cash flow issues, and additional overhead.

4. Unhappy customers and higher churn

Like we already covered in the introduction, over 8 in 10 customers will never do business with a brand again after experiencing a delivery mistake.

And that’s just the tip of the iceberg: 98.1% of shoppers say delivery impacts their brand loyalty. So with every mistake, you risk losing potentially-loyal customers.

Causes of Inaccurate Shipping

A product goes through a lot of different stages in the supply chain before it ends up at the door of a customer.

Order fulfillment is a complicated process. From receiving, distributing, and storing inventory, to picking, packing and shipping orders (with a packing slip), any slip up at any stage can cause a package to get lost or mixed up (sometimes called delivery exceptions).

In this section we’ll cover the four primary causes of inaccurate shipping.

#1. Human errors during the receiving process

With tens of thousands of products coming into a warehouse, ongoing inventory management is a significant challenge. It’s almost a guarantee that there will be some human errors during the receiving stage.

But since picking and packaging make up the majority of operational costs for warehouses, many businesses skimp on auditing incoming inventory.

And that results in inaccurate labeling, inaccurate inventory counts and misplaced products.

#2. No automated system for picking

By combining a label-based system with barcodes or RFID (Radio-Frequency Identification), you can ensure that the picker chooses the exact SKU for each order — resulting in up to 67% fewer errors than with a paper-based system.

Automated systems are a necessity for large scale e-commerce fulfillment. For each order, a pick ticket will give your warehouse pickers the information they need, including location and SKU.

#3. Limited or non-existent auditing or verification process

After products are initially picked, an auditor should confirm each order with care. If you use a WMS (Warehouse Management System), you can also use weight verification to verify that the selected SKUs match the order description.

Without a process in place for auditing your warehouse, orders can get mixed up before even reaching a distribution center.

#4. Bad route planning and driver error

On the delivery side of things, poor delivery route planning, inaccurate mapping from digital tools, and human error can lead to delays, and (sometimes), even products being delivered to the wrong destination.

How Can I Improve My Shipping Accuracy?

To make sure that you pick, package, and ship the right products at the right time, you need to create a reliable, repeatable fulfillment process for your staff at all levels.

Third-party logistics providers can also help your business improve several stages of this process.

1. Audit all incoming inventory

The first step is to make sure that you correctly label and place all incoming products from your suppliers.

Warehouses with high rates of inventory turnover will have new products coming in on a regular basis. Everything must go right — from using the right barcode label to storing goods in the correct warehouse section.

Put in place an audit process to minimize your error rate and set up the rest of the fulfillment journey for success.

- Communicate with suppliers and schedule predictable receiving appointments

- Have separate staff members double check all labels and product tags

- Don’t rely on a single product count, use at least two

- Always confirm that new products are in the right place as part of the put-away process

- Only sign Proof of Delivery (POD) after verifying the contents of the shipment

2. Use a reliable verification process for picking

Next, you need to use a WMS and put in place a reliable verification process, like weight verification or tag auditing, to make sure that warehouse staff is picking the right products for each shipment.

With careful inventory control, you can also ensure that there’s no chance for pre-picking errors trickling down.

3. Optimize loading by truck specifications and territory

Once the orders are on the truck, you can’t take back and fix any mistakes without impacting delivery time. Ensure that your loading process clearly separates batches by required truck specifications, like refrigeration or cargo size, and order destination, so no driver ever loads up the wrong pallets.

With OptimoRoute’s load planning tools, you can categorize trucks and drivers based on capacity, special characteristics, and driver territory.

Reduce your operational costs by 30%

Increase delivery capacity by 43%

Plan 7x faster

4. Optimize your routes for on-time shipments

Delivering your on-time according to your ETA is the second part of keeping your end of the shipping bargain with your customer.

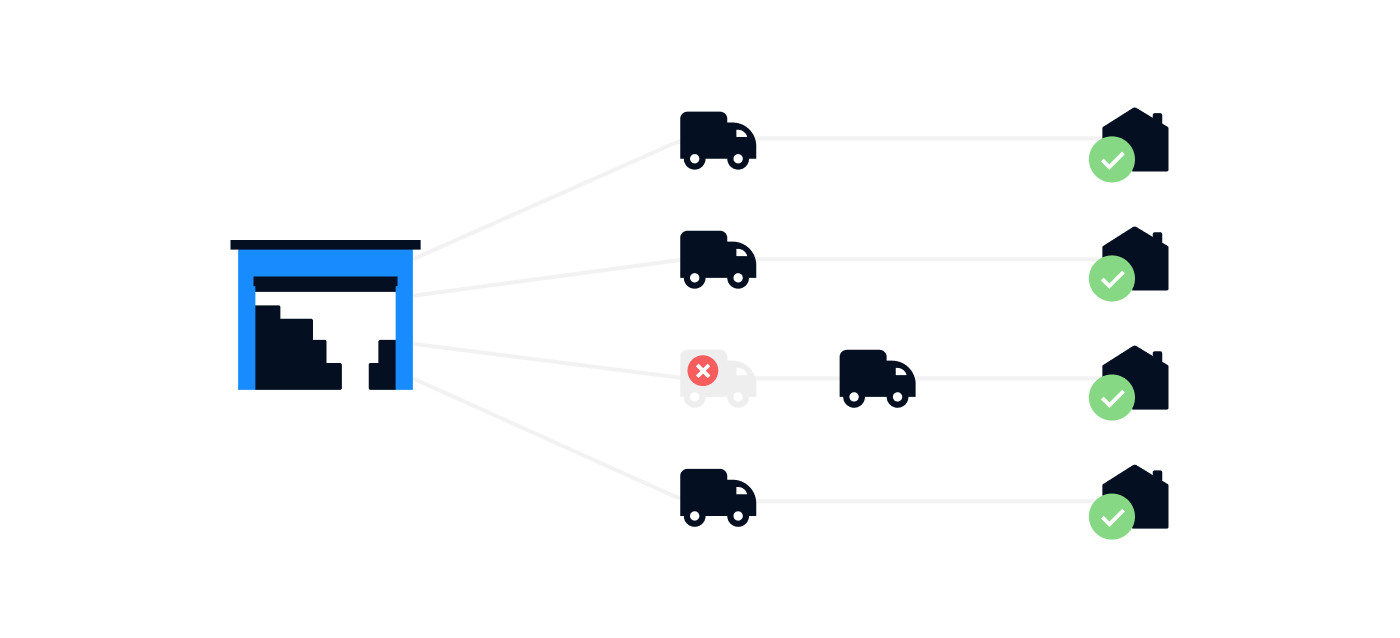

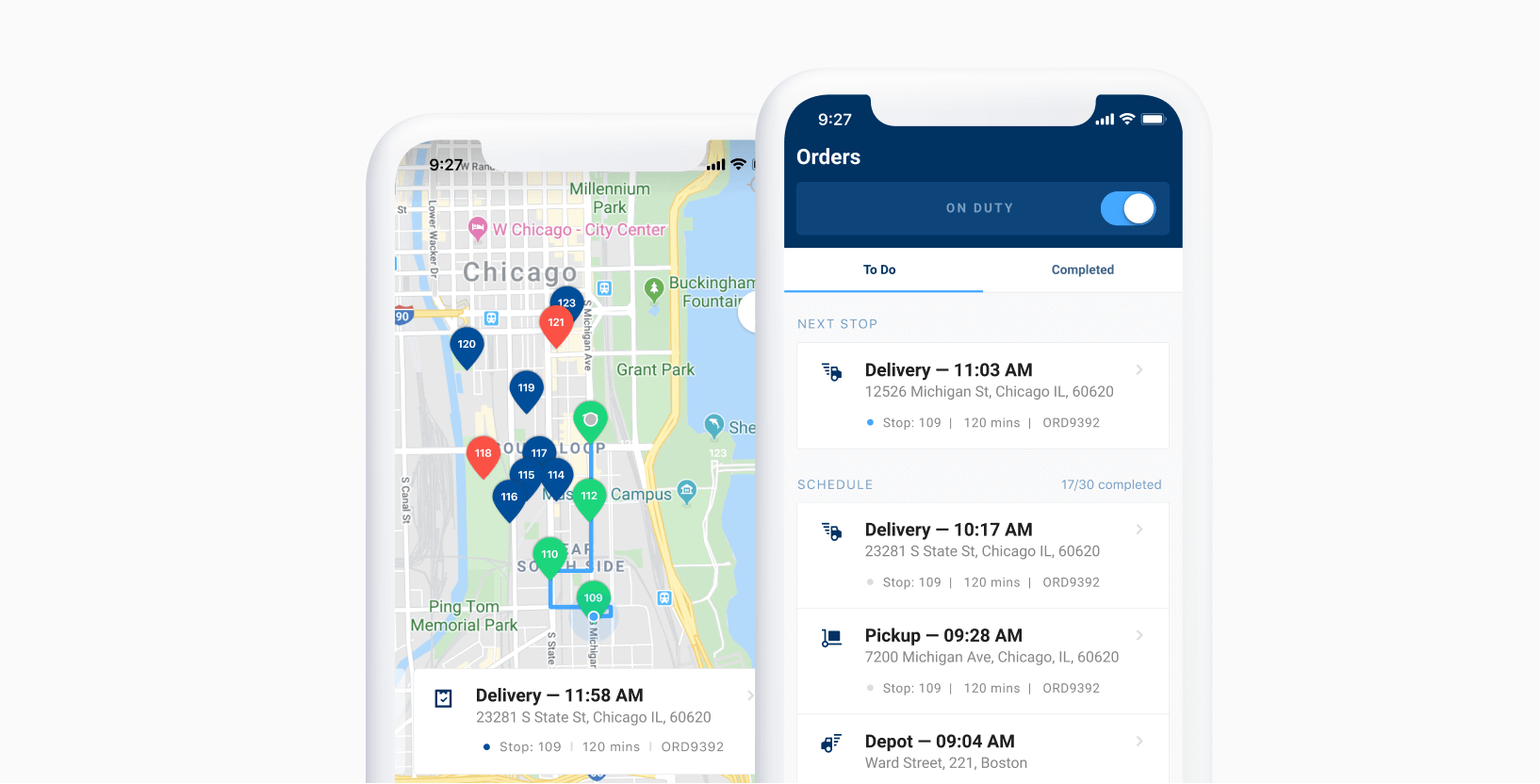

Route optimization is easy with OptimoRoute’s smart route planning features. Import orders in bulk and our software will plan the most efficient route, considering time windows, vehicle capacity, driver breaks, and other factors.

Our mobile app will help keep your drivers on track. And since there is no manual input, there is no risk of mistyping an address and ending up in the wrong place.

By just implementing our solution, Hardie’s Fresh Foods was able to improve its on-time delivery rate by 5% while reducing their mileage by 20%.

5. Plan delivery and pickup windows around your customer

When ordering home delivery, most shoppers prefer to receive packages in person. To make that possible, your delivery drivers have to maintain a flexible route to adapt to different customer schedules.

With OptimoRoute, you can set unique delivery and pickup time windows, which will automatically be factored in when planning routes for your drivers. This feature helps minimize missed delivery times and failed deliveries without time-consuming manual planning.

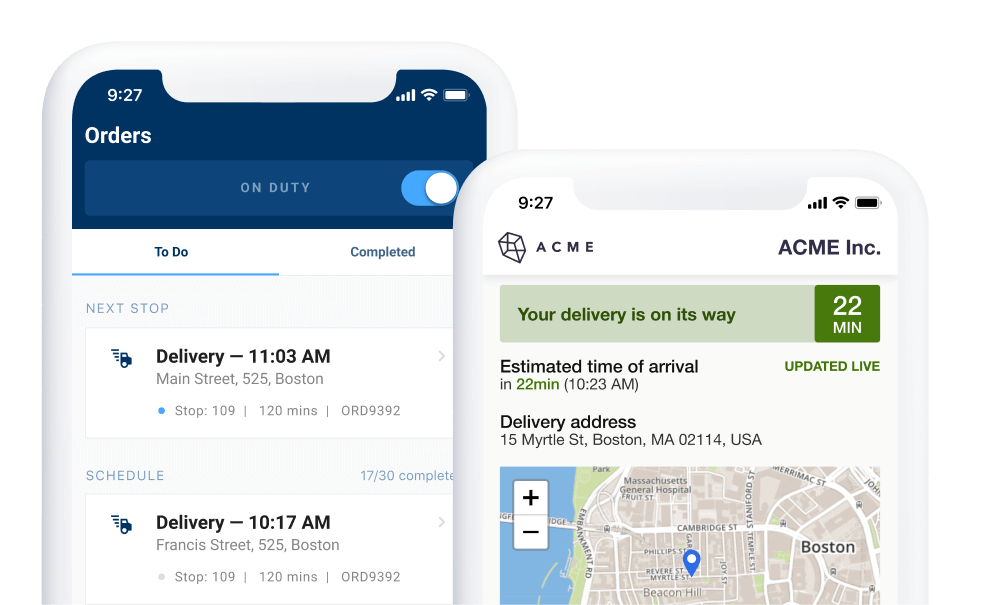

6. Set up order tracking

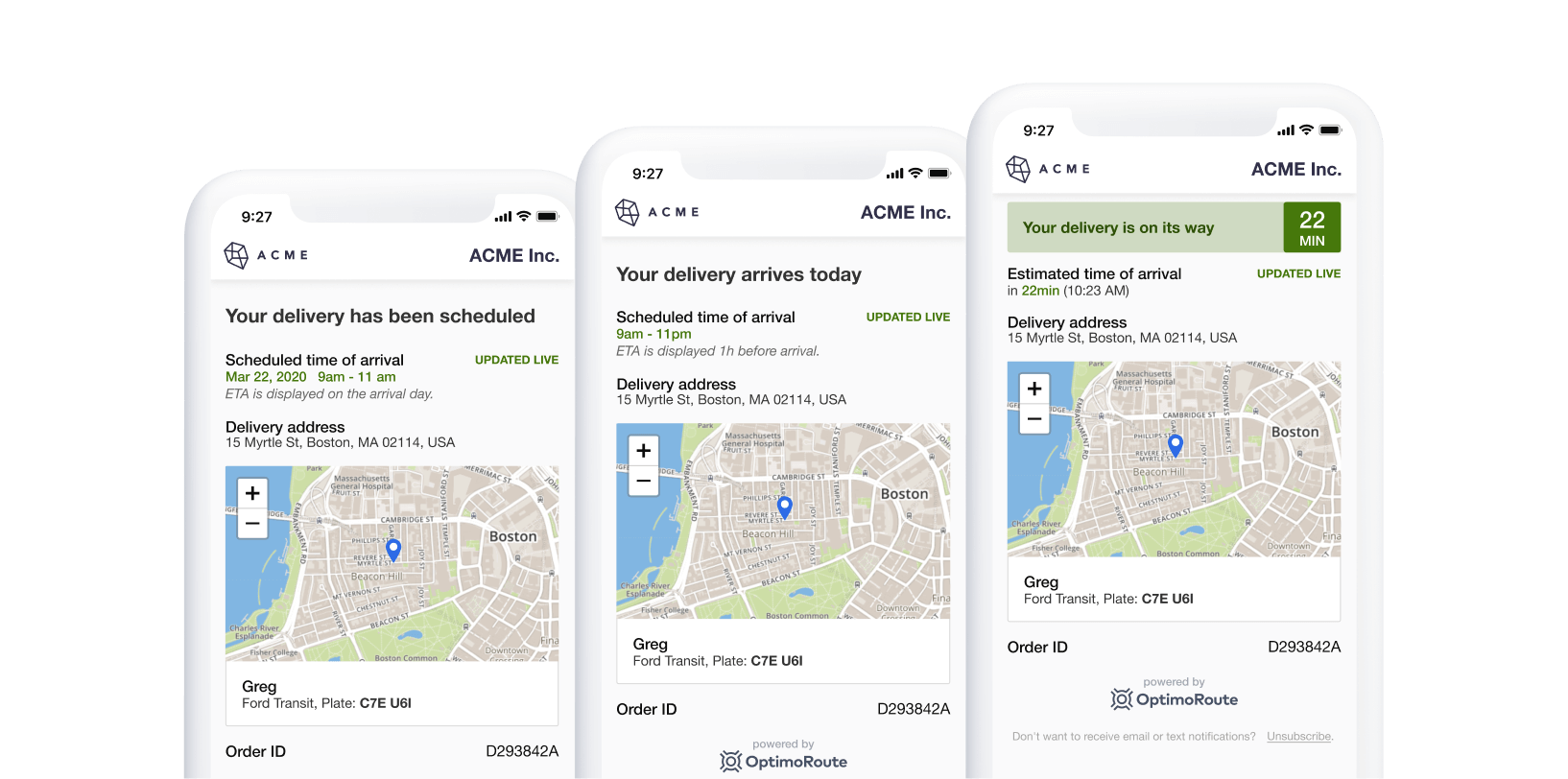

Another thing that can help reduce failed deliveries and stolen packages is Realtime Order Tracking and notifications. Modern customers have grown accustom to expecting delivery/package tracking.

With OptimoRoute, automated order tracking with live updates helps keep your customers in the loop.

7. Track and continually improve accuracy rates

The final step is to track your accuracy rates and strive to optimize them over the long term. Unfortunately, it’s just not feasible for your managers to do this manually.

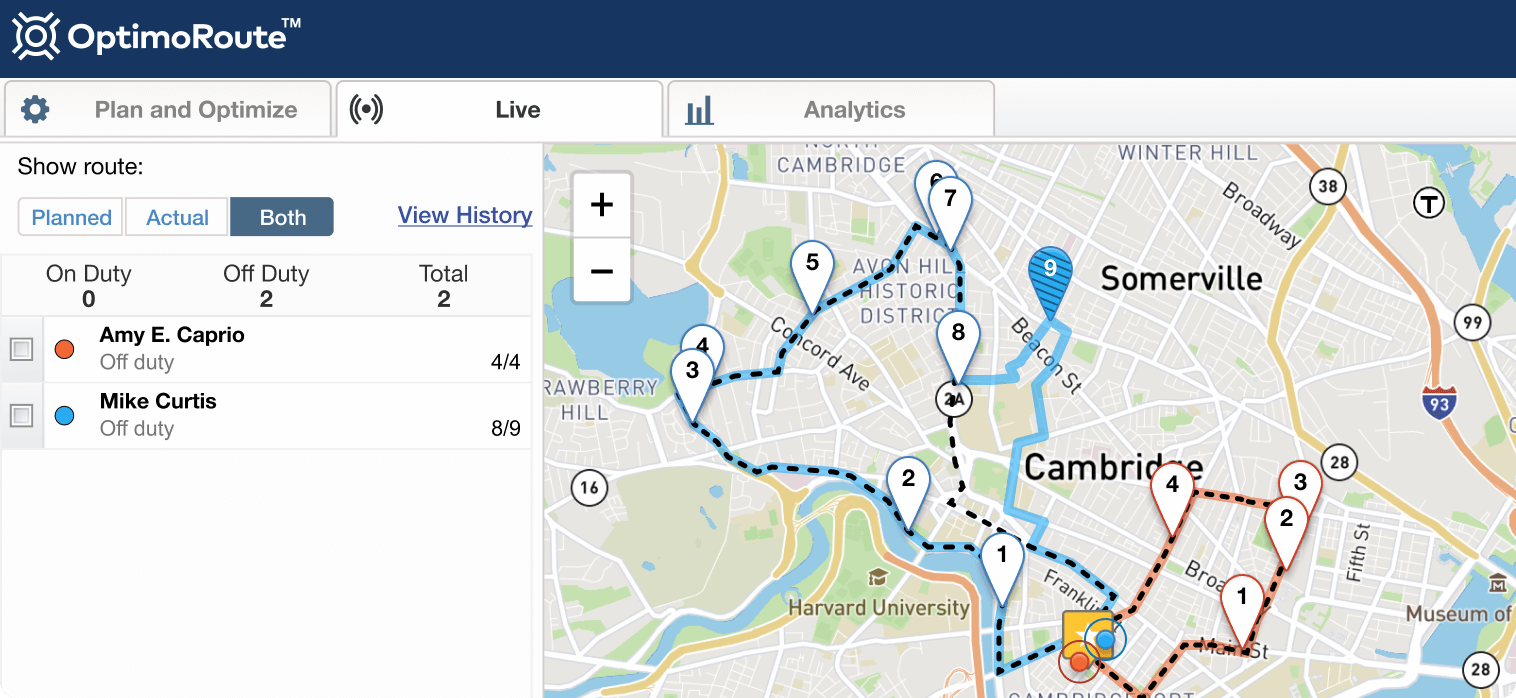

Luckily, with OptimoRoute, you’ve got fleet management features at your fingertips, including live GPS-tracking of all your drivers through the app.

You can even compare historical driver data with our breadcrumbs feature. It shows the real way a truck drove compared to the planned route.

This dashboard makes it easier to determine why they drove there later (road closures, detours, etc.).

Drivers also use the mobile app to confirm delivery statuses, which helps your dispatchers track deliveries in real time.

You can even tie employee incentives like quarterly bonuses to key performance indicators like on-time delivery rates.

How 2 Guys With Knives Optimized Their Shipping Accuracy With OptimoRoute

2 Guys With Knives is a Vancouver-based meal-kit delivery service. Its old solution for planning last mile delivery left a lot to be desired. The founders manually planned the routes, which made missed deliveries and repeated orders a nightmare.

With OptimoRoute’s last mile delivery software, they can quickly reroute drivers to account for last-minute changes like cancellation. Smarter route planning helped the company maximize the amount of on-time deliveries with a limited fleet of delivery drivers.

In addition, real-time order tracking with notifications has helped minimize the amount of failed deliveries due to preoccupied customers. With OptimoRoute’s Live ETA, customers knew precisely when they should expect the knock on their door.

Final Thoughts

If you deal in any type of physical product, the first step of the customer experience is ensuring they receive the right product on time. Failing on this step leads to a bad experience for your customer and bad word of mouth for your company.

By getting things right, you can start building a loyal customer base and minimize unnecessary contacts to customer service.

With OptimoRoute, you get access to enterprise delivery optimization features like live order tracking, real-time route modification, workload balancing, and more. They help you keep your fleet of drivers consistently delivering on time. You will also avoid failed deliveries caused by bad communication, with real-time order data right there in the app.

Try OptimoRoute™ for Free

No installation or credit card required