Order Fulfillment Strategies & How to Speed up Your Process

6 min read

How fast you get your order to your customers can make or break your business.

In a 2019 survey by Digital Commerce 360, 44% of consumers who didn’t complete a purchase said they canceled because the product wouldn’t arrive on time.

Consumers are less patient than ever. According to Statista, in 2019, only 34% of consumers are willing to wait more than two days for an order to be shipped and delivered.

By optimizing your order fulfillment process, you can speed up your deliveries and order accuracy. Less waiting time means happier customers, and more orders and revenue for your business.

In this guide we’ll cover the basics of order fulfillment, the three main models, and how you can speed up and optimize your order fulfillment services.

Let’s dive right in.

To navigate to the section which interests you most, click below:

- What Is Order Fulfillment?

- What Is the Order Fulfillment Process?

- 3 Main Order Fulfillment Models

- How to Optimize In-House Order Fulfillment With OptimoRoute

What Is Order Fulfillment?

Order fulfillment is the receiving, processing, packaging, and shipping of an online (or mail) order to customers.

It’s the process of taking an order and preparing and delivering the right products. Like a waiter, but on a national, or even international scale.

The process of order fulfillment involves a lot of steps, including some you may not have thought about before.

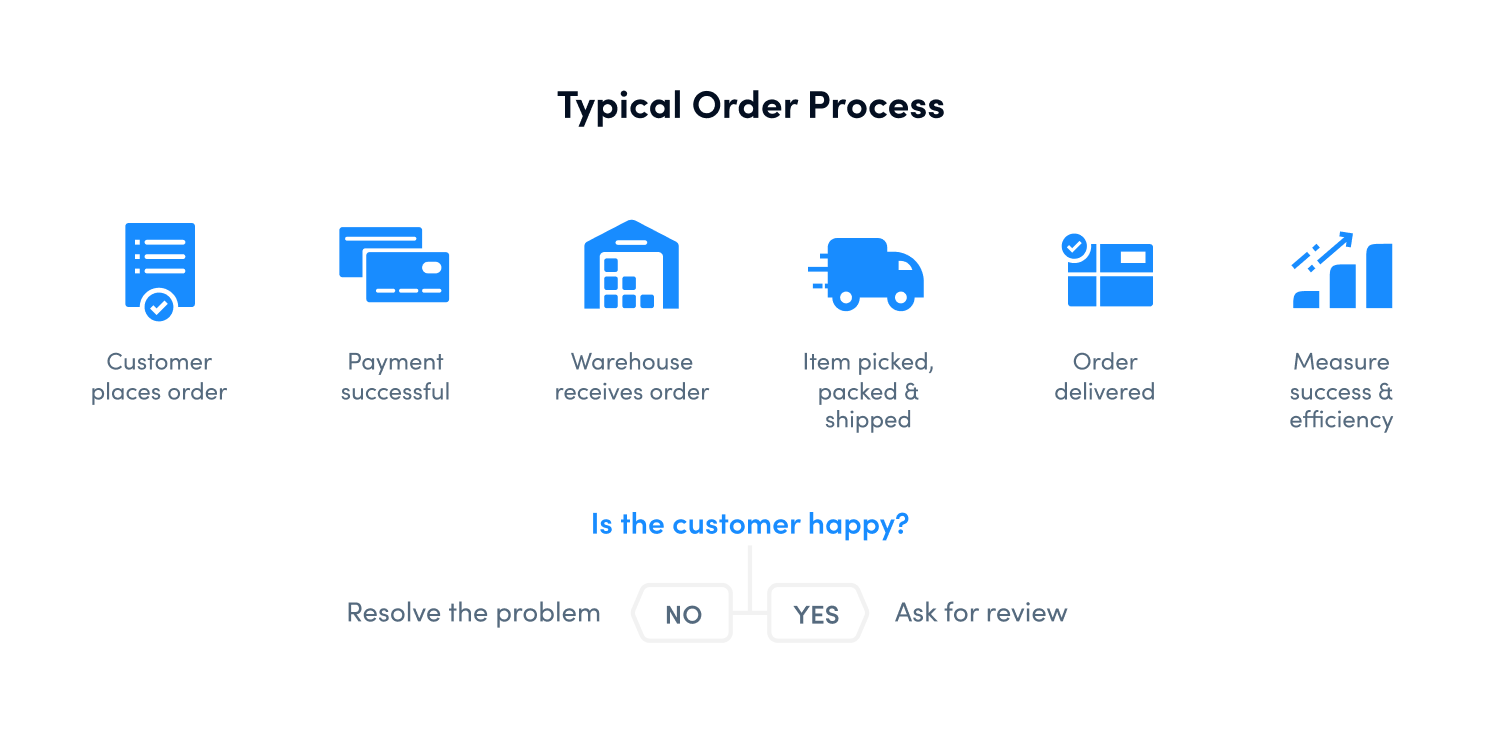

What Is the Order Fulfillment Process?

The order fulfillment process includes everything from inventory and warehousing to order processing and the packaging and delivery of ordered products.

Outbound logistics is another term that covers many of the same processes.

Let’s take a closer look at the step-by-step process of fulfilling an order.

Inventory management

The first step happens before the customer even places an order.

Retailers must keep extra inventory in warehouses and distribution centers at all times.

If not, they can’t ship ordered products to customers on time. It’s that simple.

That’s why most companies keep at least a month’s supply. According to the US Census Bureau’s 2020 report, US companies keep 1.37 times monthly sales in inventory, on average.

Order processing (picking and packing)

After a customer places an order and you confirm the payment, the nearest warehouse must process the order.

First, they must find and pick the products, then package and prepare them for shipping.

Shipping and last-mile delivery

When the ordered items are ready, it’s time to ship them. You can either deliver the package with an in-house delivery fleet or outsource last-mile delivery to another company.

The modern customer doesn’t like to wait. They expect the whole process, from order to delivery, to happen within two days or less.

And that’s on average. Have you ever met a millennial? Anything slower than next-day and they’re not buying from you again.

Returns processing

Finally, you need to handle requests for returns and replacements. If a customer really received a faulty product, you need to replace it ASAP. If you don’t, your reputation is at risk.

With more impatient consumers than ever before, each step of the process has to be optimized and handled efficiently.

But the method depends on how you handle fulfillment.

Check out our page on returns management for more.

4 Main Order Fulfillment Strategies

Let’s take a closer look at how businesses manage order fulfillment operations. Every business does it differently, and some models have more going for them than others.

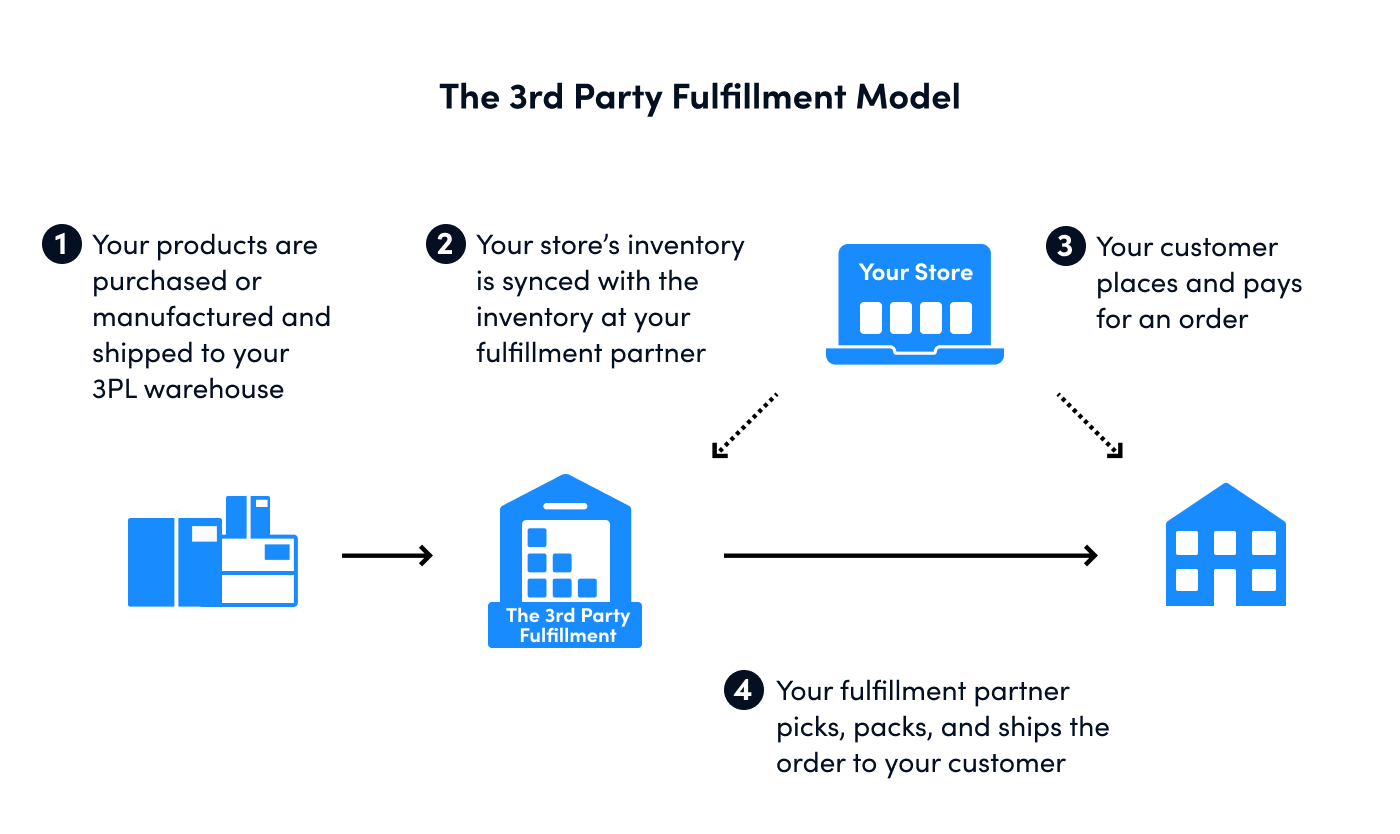

1. Third-party fulfillment

With the complete third-party fulfillment model, you leave everything up to a fulfillment service. That includes warehousing, inventory management, and shipping.

A common example would be a manufacturer using Amazon FBA fulfillment centers to handle its online order fulfillment from top to bottom.

According to Korn Ferry’s 2019 Third-Party Logistics study, 69% of companies that use a 3PL service outsource warehousing, and 81% outsource domestic transportation.

So the majority of companies that go third-party leave everything to their partner.

Pros

- No need to rent warehouse location

- Less staff on payroll

- Easy to set up

Cons

- Limited control over package and order handling

- No control over shipping accuracy

- Can complicate returns management and frustrate customers

2. Partial third-party fulfillment (delivery)

Some companies only outsource the delivery aspect of fulfillment, handling warehousing and inventory in-house.

Think large retailers like Target that work with UPS and FedEx to ship orders, and local stores that use a service like DoorDash.

Pros

- Full control over package/order handling

- Less staff on payroll

- Easy to set up

Cons

- Warehouse/distribution centers needed

- Limited control over shipping accuracy

- Can complicate and frustrate customers

3. The self-fulfillment model

This is often a great option for local businesses and large-scale ecommerce businesses alike. Just consider your local newspaper boy and Amazon Prime.

Pros

- Full control over package/order handling

- Full control over shipping accuracy and on-time delivery rates

- Faster in-house returns management which can boost customer satisfaction

Cons

- Warehouse/distribution centers needed (non-issue for local businesses)

- Need more staff on payroll

- Difficult to manage process (without the right tools)

It’s difficult to handle fulfillment in-house unless you have the right tools at your disposal.

To do it all without a logistics management system, you’d need Rain Man on your payroll.

Luckily, OptimoRoute can help you plan, schedule, and route deliveries at scale, while considering real-life variables like time windows and loading times. And warehouse management systems (WMS) like Logiwa can help you with warehousing, picking, and packing.

4. The dropshipping model

Dropshipping is when you forward orders to a third-party wholesaler or manufacturer. You have nothing to do with the supply chain beyond the sale of the product.

Because you don’t handle any of the fulfillment, you have zero control over the speed or handling of your orders.

Pros

- Requires no inventory storage or warehousing.

- Lower staffing costs (no delivery drivers, etc.)

- Low or no shipping costs.

Cons

- No control over the entire fulfillment process.

- Minimal control over customer satisfaction.

- Low profit margins.

How to Optimize In-House Fulfillment With OptimoRoute

If you’re handling it internally, you’re probably wondering how can my order fulfillment process be improved?

With OptimoRoute, you can optimize your in-house ecommerce order fulfillment from start to finish. Automatically divide customer orders equally (by work hours or order volume) among your delivery drivers, and consider other factors like vehicle capacity, time windows, and more.

Speed up order planning and scale with increased demand to always deliver on time

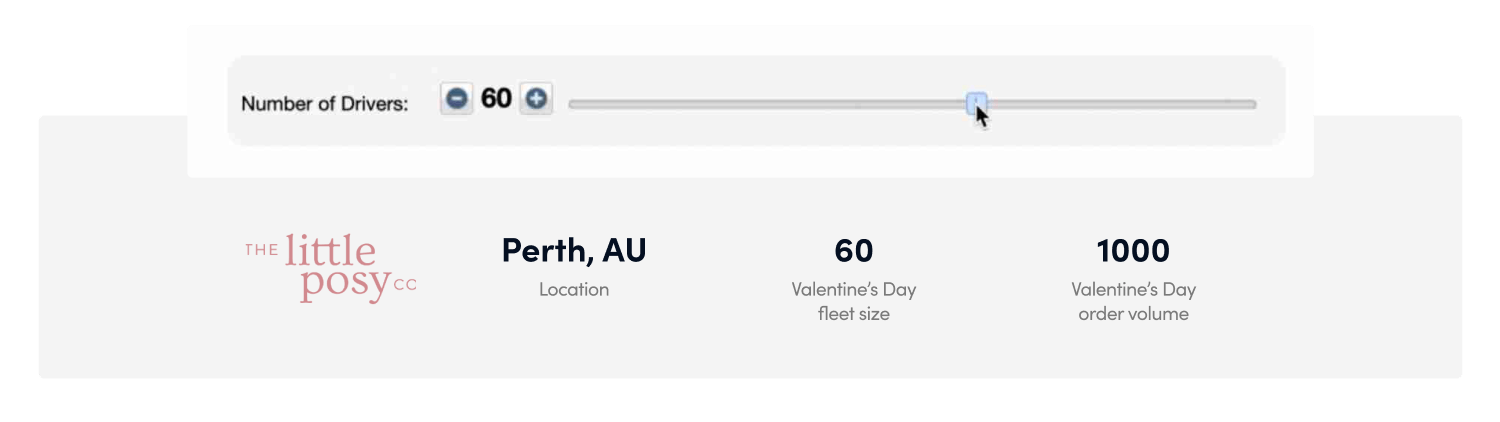

With OptimoRoute’s effective route planning tools, you can complete your delivery route planning in minutes, rather than hours. This speed, along with OptimoRoute’s flexibility, makes it easy for companies to scale with demand, and still keep their deliveries on time.

OptimoRoute client The Little Posy Co, for instance, was able to deliver five times their normal number of orders around Valentine’s Day.

With our smart features, they scaled their fleet and met the increased demand without issue.

Faster deliveries = more loyal customers

With up to 82% faster planning and more efficient routes, the bottom line is that your deliveries will be faster. But what’s the big deal?

Customers that receive packages faster are more likely to buy from you again. According to a 2019 study by Convey, the delivery experience impacts the brand loyalty of 98.1% of consumers.

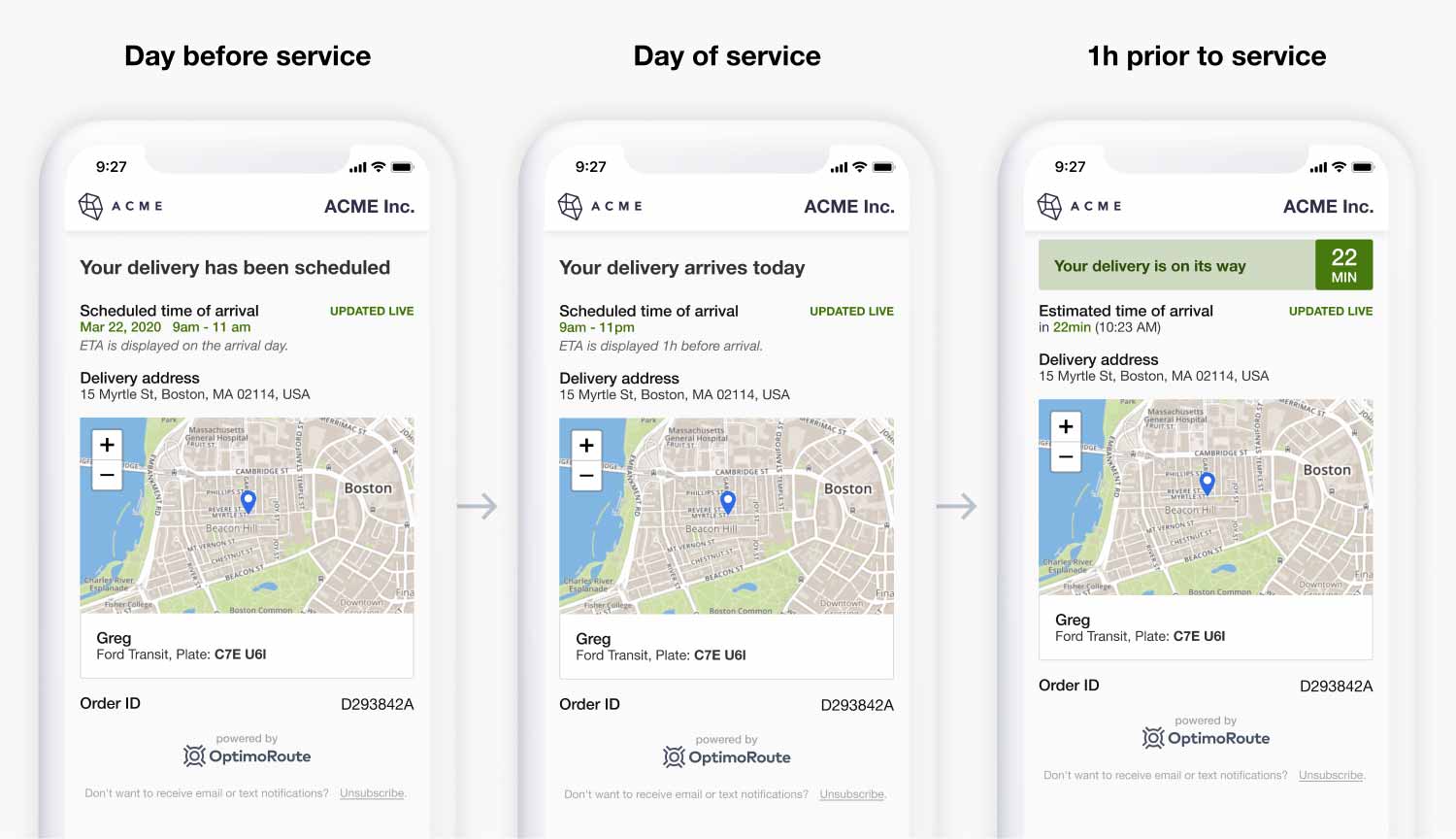

Improve customer experience with real-time order notifications

Customers don’t like surprises (unless they involve the word “free”). Improve your customer’s experience with real-time ETAs of their orders.

Not only will your customers be happy, you’ll reduce failed deliveries at the same time.

Third-party app integration through our robust API

You can easily use our API to import or export necessary information, to create an even more fluid order fulfillment process.

You could for example automatically import driver schedules from your ERP system.

Our API has all the endpoints and hooks your developers could dream of. They can easily use it to create complex workflows that eliminate most of the tedious manual labor.

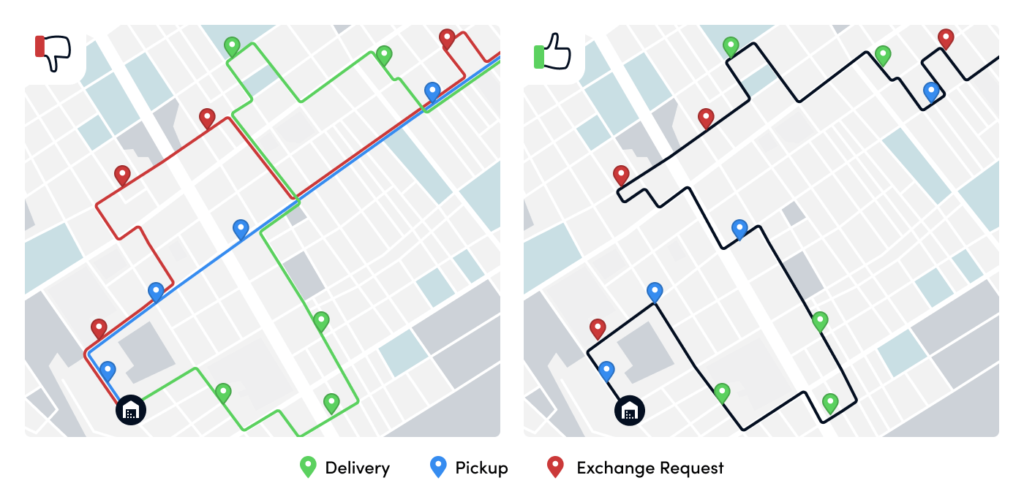

Combine reverse logistics pickups with your deliveries

Do you use reusable containers or packaging to deliver products to your customers?

With OptimoRoute, you can integrate your reverse logistics into your driver’s daily delivery routes.

There are pros and cons to every order fulfillment model, but doing everything in-house sure has its advantages.

With full control over package handling and delivery, you can make sure to meet all customer expectations.

OptimoRoute will help you manage the complex process of planning and routing deliveries. Your dispatchers will go from feeling understaffed, to having too much free time on their hands.

A better customer experience will help you build a loyal customer base and improve your bottom line.

To see how OptimoRoute can help with your order fulfillment start your 30-day free trial today.

Try OptimoRoute™ for Free

No installation or credit card required