The Returns Management Process: How to Make the Most Out of Returns and Exchanges

Last year, an average of 8.1% of all products that were purchased were returned.

The rates can be even higher for companies that rely 100% on e-commerce sales and offer free returns. Handling outbound logistics is already a challenge, but if one in five products you deliver are sent back, it becomes a massive and costly operational challenge.

But if you do returns management right, you can ensure that you keep the business impact of returns to a minimum.

In this article, we’ll cover the actual step-by-step process of managing returns, best practices, and real examples of companies using returns management as a competitive advantage.

To navigate to the section which interests you the most, click below:

- What Is Returns Management?

- Returns Management Process

- Returns Management vs. Reverse Logistics

- What Is a Return & Refund Policy — And How to Use It to Drive More Sales

- 3 Examples of a Returns Process as a Competitive Advantage

- Returns Management Best Practices

- Returns Management FAQ

What Is Returns Management?

Returns management is a process in retail and e-commerce that starts with customers wishing to return a product, and ends with the business collecting, organizing, and restocking that product. By properly managing returned products you can significantly cut losses by using undamaged returned items to restock warehouse inventory for resale.

Returns management, or reverse logistics, goes beyond the final delivery and is not used for every customer order. A returns management process is part customer support, part logistics, and part inventory management.

Returns Management Process

The process of returning a product purchased depends on whether it was purchased in-store or online.

For e-commerce businesses and large appliances with home delivery options, these are the stages the product will go through:

1. Customer receives product, is unhappy, and requests a return or refund

The returns process starts when a customer decides they aren’t happy with the product. Maybe the product was damaged, or in the case of apparel, it might just be the wrong size or color.

The customer requests a return, refund, or exchange from the company that delivered the product using the proper channels.

2. Company approves or disapproves the return, exchange, or refund

Your service staff or dedicated gatekeepers will decide whether or not the customer is eligible according to your company’s returns policy.

3. The company picks up the product from the delivery address

Companies that handle returns internally often struggle to optimize the routes of both deliveries and pickups as last-minute orders are difficult to adapt to.

Companies that rely on third-party logistics (3PL) providers will typically use digital prepaid shipping return labels if they cover product returns.

4. The product is delivered back at the sorting facility or warehouse and inspected

A delivery driver returns the product to a dedicated sorting facility or major warehouse. The product is sorted, organized, and inspected for quality.

Why did the customer return the product? Was it damaged during the delivery and return process? Is this product good enough to restock?

After the products are sorted, an auditor will inspect all the returned products and try to answer those questions.

5. The product is restocked and put back in inventory

If the product is in a suitable condition, it will be restocked on the warehouse shelves, added to the inventory count, and can now be sold to a future customer.

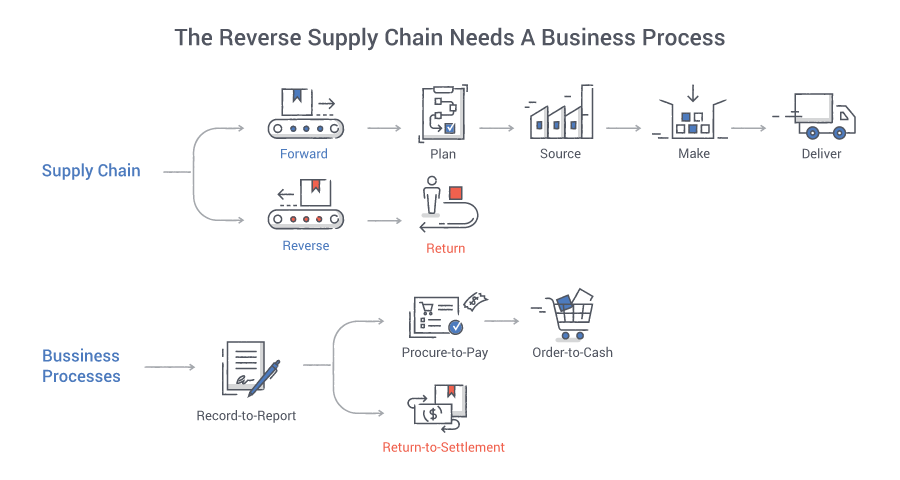

Returns Management vs. Reverse Logistics

Reverse logistics is the process of retrieving returned products, rental products after term, or reusable packaging from customers, and sorting and delivering it to appropriate locations.

Having a tried and tested reverse logistics process is a great way to optimize how quickly returns are picked up and processed, and minimize the gas and time expenses that are used in picking up a return. Another option is to hire a reverse logistics company to take care of the process for you.

Logistics is, of course, a key part of returns management, but managing returns also involves preventative measures, software integrations, and other things not typically considered when using the term reverse logistics.

Reduce your operational costs by 30%

Increase delivery capacity by 43%

Plan 7x faster

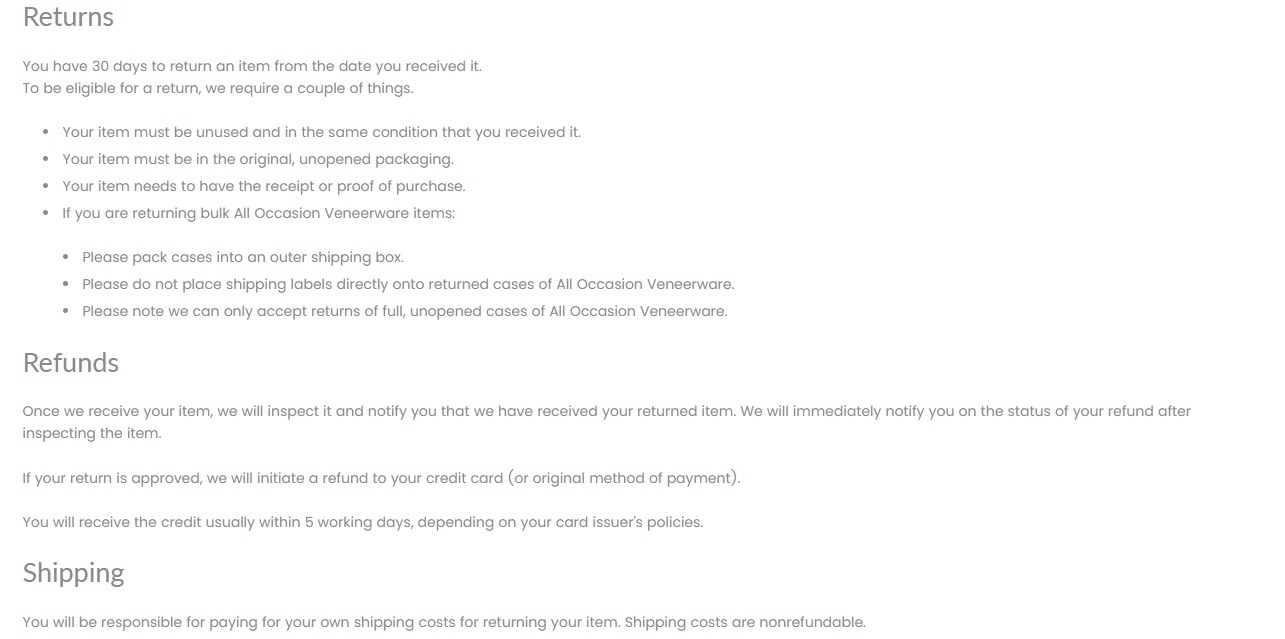

What Is a Return & Refund Policy And How to Use It to Drive Sales

A return and refund policy is just what it sounds like — a policy that lays out the terms for returning or applying for a refund for one of your products.

You need to cover the conditions for the return, like the valid period, whether the product can be used, if it needs to be in the original packaging, as well whether or not you cover shipping.

Most companies include their return & refund policy as an afterthought as part of their shipping policy. But that’s not enough.

73% of consumers in 2019 said the returns experience affects whether or not they would keep shopping with a brand.

If you can meet these expectations, make sure your policy is visible on your website and in your online store. By doing so, you can win customer loyalty and set up a competitive advantage for your business.

3 Examples of a Returns Process as a Competitive Advantage

In this section, we’ll explore three companies that have used a properly-managed returns process and aggressive return policies as a competitive advantage to conquer their industries.

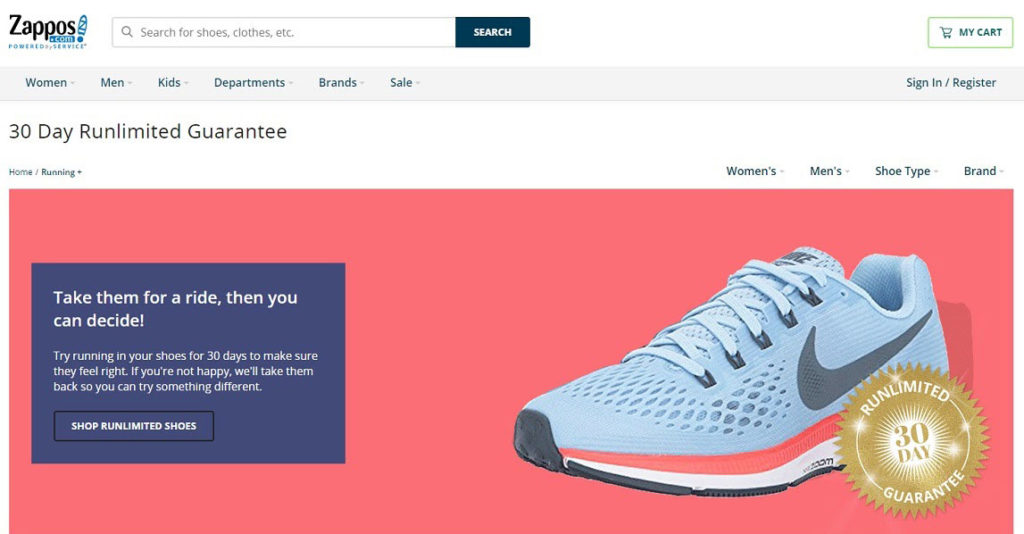

Zappos Allows Free Returns of Used Shoes

Unlike established competitors, Zappos understood that the fit of a shoe is integral to whether or not a customer will be happy with a purchase, not just price or shipping times.

So rather than competing on price with other e-commerce giants, Zappos differentiated itself by allowing customers to try on shoes and return them if the shoe didn’t fit.

This wouldn’t be possible without effective returns management and proper quality control.

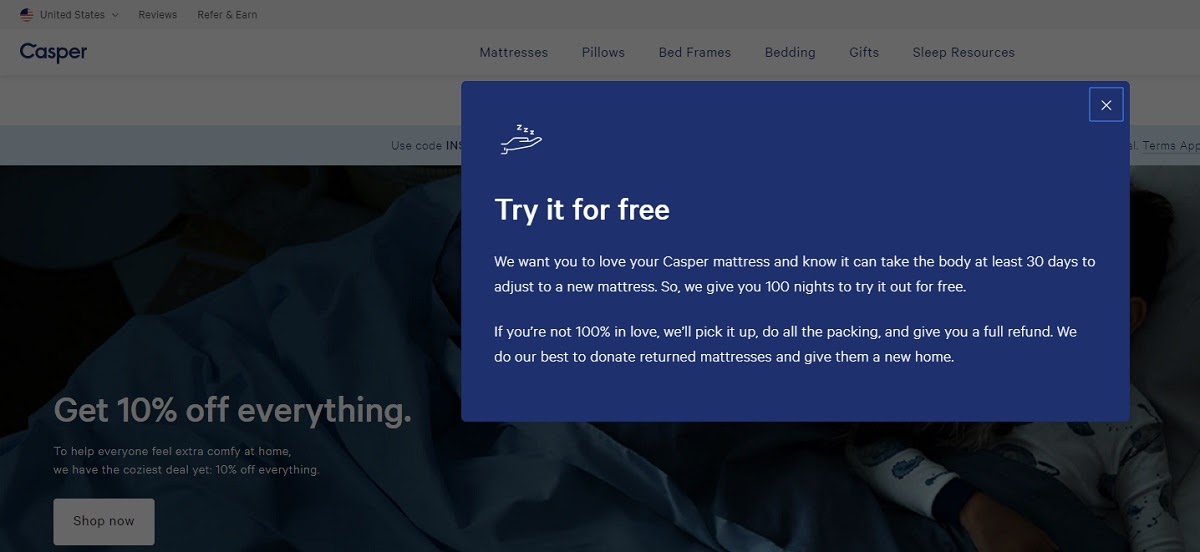

Casper Makes a Splash with a 100-Night Return & Refund Policy

The mattress industry is notorious for its “you break you buy” policies, typically meaning if you even lie in a mattress once, you won’t be able to return or exchange it unless you can prove a manufacturing flaw.

Then, Casper came along and changed that with its 100-night (get it?) return and refund policy, and changed the game. The policy became a huge competitive advantage and driver of word of mouth marketing and customer loyalty.

Casper works closely with UPS and other shipping partners to make this happen, tracing products from warehouse to door, and coordinating on logistics so their own staff can come in and help customers with the mattress as part of the delivery process.

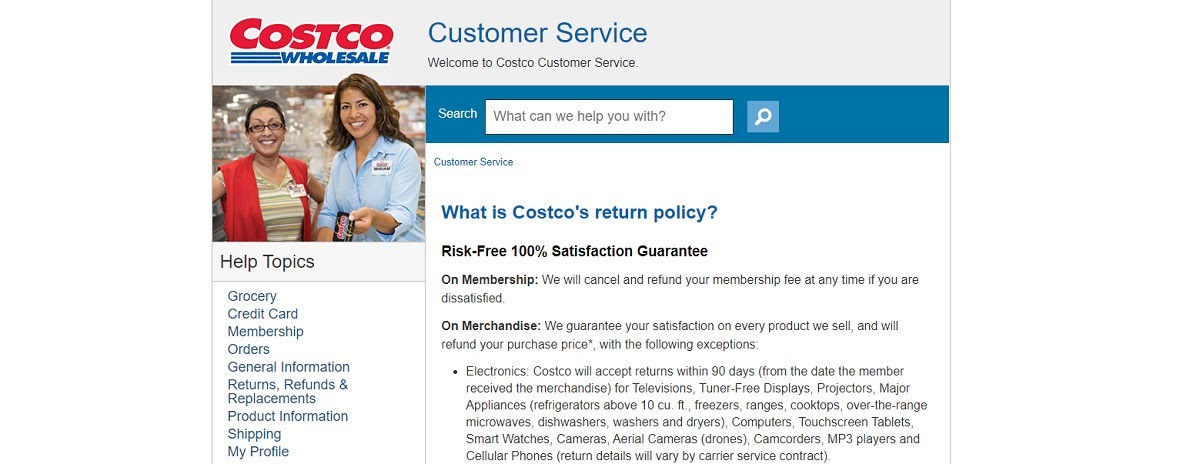

Costco Puts Customer Satisfaction First

While the online policy highlights a lot of specific conditions, most customers experience the process of returning items as quickly and painlessly as possible.

You can even return online purchases to stores, even if your local store doesn’t carry the product you bought.

Costco has entered a partnership with InstaCart to manage online sales and deliveries, as well as the related uptick in returns that usually comes with e-commerce sales.

Returns Management Best Practices

For large companies with thousands of outgoing deliveries and incoming returns each week, it can be difficult to efficiently manage your workforce and maintain your profit margins.

By following these best practices, you will be able to provide better customer service and improve your bottom line:

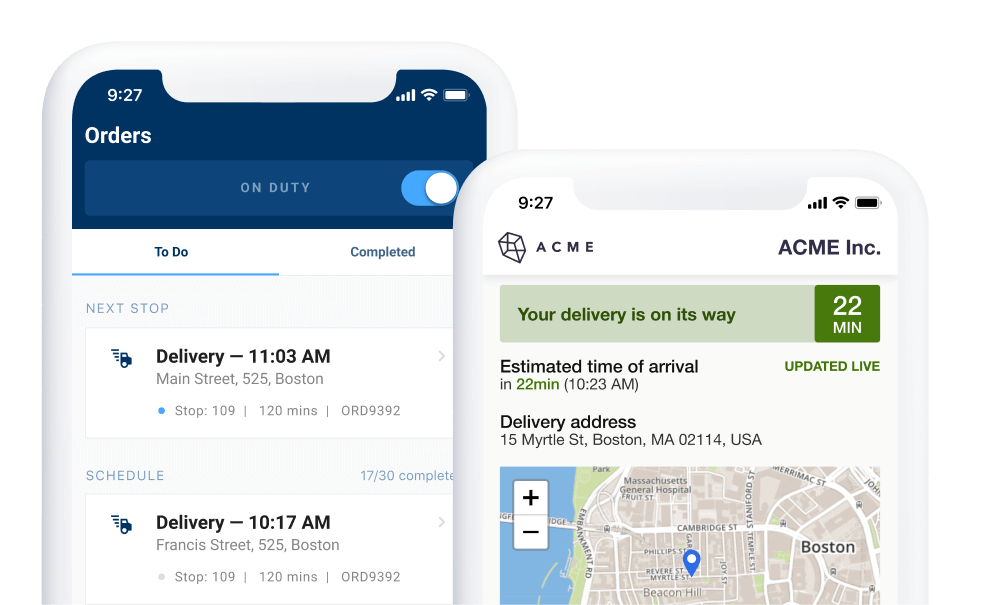

Incorporate reverse logistics into your deliveries

If you haven’t already, start incorporating reverse logistics processes into your regular deliveries.

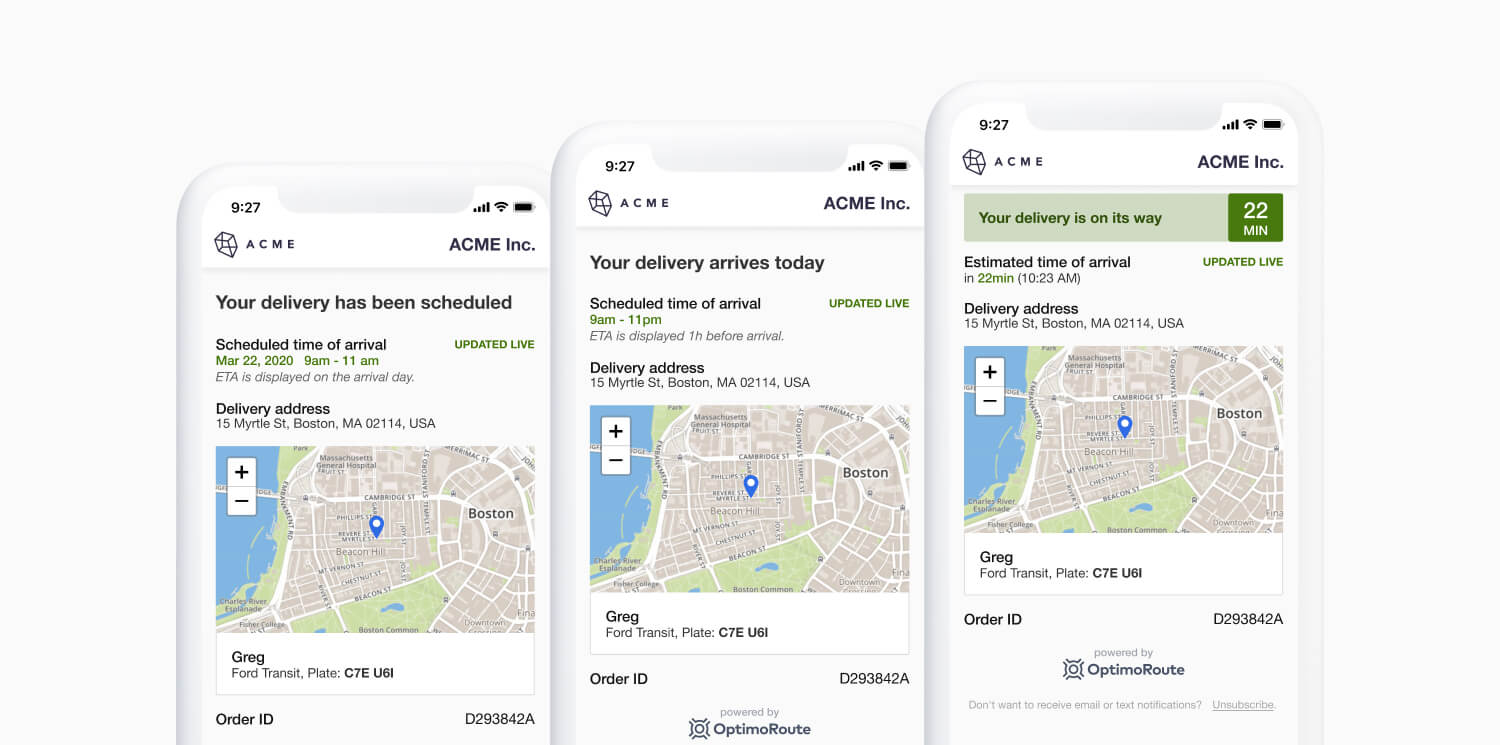

With OptimoRoute’s real-time driver tracking, it’s easy for dispatchers to redirect drivers to respond to last-minute orders or returns.

If a delivery driver is already in the neighborhood, the ability to quickly redirect them to make a return pickup delivers a great customer experience and helps your company save mileage and working hours.

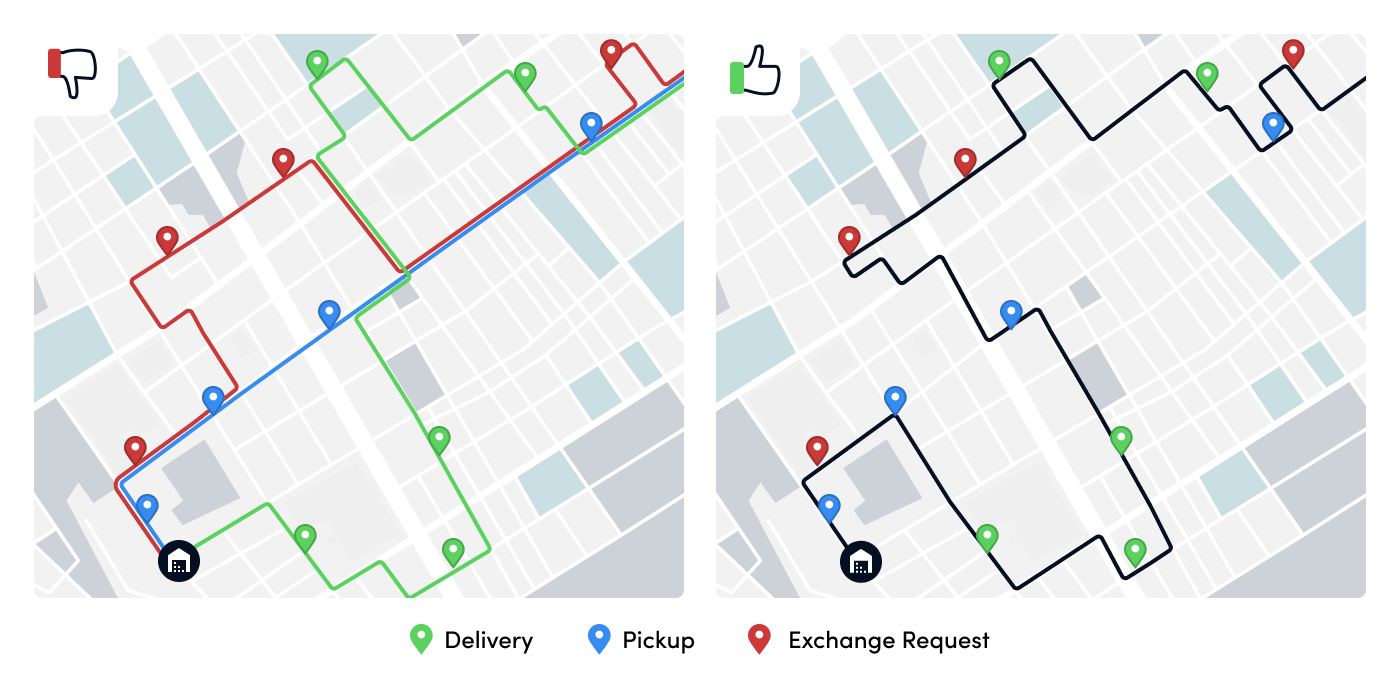

Plan routes for both returns and deliveries

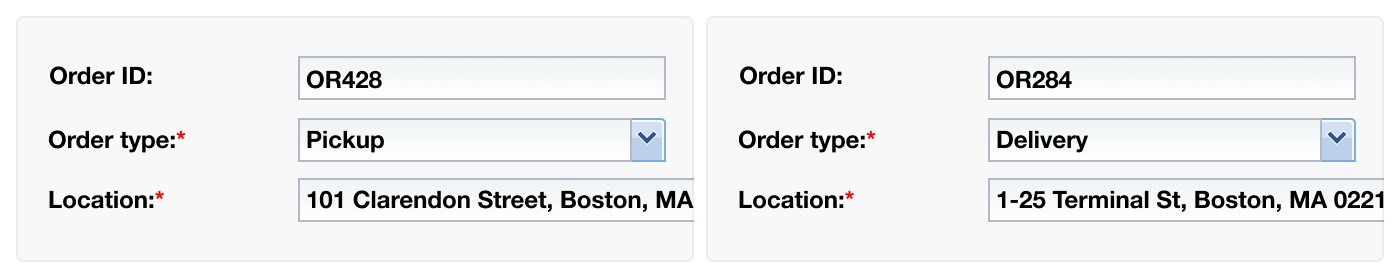

When planning a schedule and routes for deliveries, include product returns into the process as well.

With OptimoRoute’s smart planning features, dispatchers can automatically plan efficient routes that include both deliveries and return pickups, while considering both delivery and pickup time windows.

Thanks to OR’s efficient route optimization features, Hardie’s Fresh Foods’ drivers always get the most efficient routes and save, on average, 20% in mileage. The delivery fleet also increased its delivery capacity by 14% without adding new vehicles or drivers.

Plan ahead with returns in mind

When planning delivery routes, leave a realistic buffer based on the average quota of returns you’ll need to pick up.

Expected product returns should also impact your plans for resupplying products in warehouses.

OptimoRoute’s weekly planning features help you manage fluctuating demand without increasing your workforce or delivery fleet.

Increase capacity for holidays

It’s not just sales, you will face a strong increase in product returns during the holiday season.

The gift-giving culture leads to a significant surge in both return and refund requests, due to wrong sizes or duplicate products.

Customers returned over $41.6 billion in products purchased online during the 2019 holiday season.

Without proper planning, this can become a huge operational headache and slow down your delivery fleet.

OptimoRoute’s flexibility makes it easy to add and remove temporary delivery drivers to your fleet and assign routes and schedules that take them into account.

Returns Management FAQ

Below we answer some of the most frequently asked questions about returns management.

What is a return merchandise authorization (RMA)?

An RMA is an authorization used by e-commerce or mail-order businesses to allow the return of a product from a customer.

Having a reliable process to inspect other potential issues (like installation and setup) before issuing an RMA can help alleviate return and exchange costs, and lead to happier customers (since their issue is fixed faster).

How do you handle customer returns?

Your company should handle returns by upholding your policies and giving your customers as little hassle as possible.

You can do this by working with a reliable shipping partner, or if you handle your own deliveries, integrate pickups and returns as part of your delivery process through reverse logistics.

What is gatekeeping in reverse logistics?

Gatekeeping in reverse logistics is the process of evaluating and accepting return requests and inspecting if returned products meet the requirements for a product exchange.

A gatekeepers’ job is basically to stop unjustified returns and make sure that only products that had a defect (not customer-caused damage) are replaced with a new problem.

What is gatekeeping avoidance?

Avoidance is the process of working to minimize returns through optimizing not just your supply chain, but also manufacturing quality control and overall product usability.

While gatekeeping focuses on handling return requests from dissatisfied customers, avoidance is focused on minimizing the number of dissatisfied customers in the first place.

A good avoidance strategy can save your company a lot of time and money, and improve your reputation with your customers.

Final Thoughts

You don’t need an expensive returns management software solution to start improving how you process returns.

With flexible route planning and fleet management software like OptimoRoute, you can include return pickups as part of your delivery process. Improving the convenience and speed of the returns service will help deliver a better customer experience, and improve your bottom line.

To learn more about how OptimoRoute can optimize your logistics, start your 30-day free trial today.

Try OptimoRoute™ for Free

No installation or credit card required