Guide to Demand Forecasting for Businesses

8 min read

You might not be able to actually see into the future, but demand forecasting allows you to do the next best thing—estimate it. Internal data, market research, and competitor analyses provide a lot of insight into what your future demand will look like. You just need to know what to look for.

In this article, we explain how demand forecasting affects your revenue, provide examples for how to conduct demand forecasting, and give you tips for responding quickly if your forecasts are wrong.

Jump to the section that interests you most:

- What Is Demand Forecasting?

- How Demand Forecasting Increases Profit Margins

- How to Conduct Demand Forecasting

- Demand Forecasting Software

- Your Predictions Were Wrong: Now What?

What Is Demand Forecasting?

Demand forecasting is the process of analyzing historical sales data and seasonal or economic trends to predict future sales. A demand forecast, or sales forecast, is an educated guess businesses use as a demand guideline, which they then use for resource and capacity planning.

Say, for instance, you own a flower shop like The Little Posy Co., and you want to know how many orders you’re likely to get in the two weeks leading up to Valentine’s Day. You would use demand forecasting to assess early February order volume from previous years and make an educated guess about how much demand you’re likely to see this year.

How does demand forecasting help with resource and capacity planning?

In order to conduct capacity and resource planning, you first need a demand forecast.

Demand forecasting estimates upcoming order volume, which you can then use to determine how many resources (workforce, supplies, and tools) you’ll need to meet demand (capacity planning). And finally, resource planning helps you allocate those planned resources and assign precise shifts to individual employees.

How Demand Forecasting Increases Profit Margins

Demand forecasting helps you avoid over- or underallocating resources, which mitigates your expenses—and protects your bottom line.

Reduces overstock and stockouts

Without accurate predictions of consumer demand, businesses wind up with too much or too little inventory. And both have a negative impact on revenue. According to RetailWire, “Overstocks are responsible for 3.2 percent in lost revenue for the average retailer, and out-of-stocks, 4.1 percent.”

The drivers of this lost revenue are numerous. When you overstock, you overpay for storage. And if you sell products with expiration dates, you also run the risk of your products going bad before they’re sold. Stockouts cost you money in lost sales (customer churn), increased procurement expenses, and more.

Many consumers will abandon their purchase when faced with a stockout, and if it happens more than once, some of your customers will never come back.

To replenish your stock quickly and keep your customers, you may wind up paying higher than normal shipping fees for rush orders. And all of these expenses are compounded, because when one product is out of stock, some customers will substitute another item from your store, which then throws off your inventory costs and demand forecasts across multiple SKUs.

Luckily, with an accurate demand forecast, it’s much easier to ensure that you have just enough inventory on hand (not too much and not too little).

Reduces overstaffing and understaffing

Understaff your business and you won’t be able to meet deadlines. You’ll have unhappy customers and, likely, lost sales. But overstaff and you’ll pay workers to stand around with nothing to do. Much like demand forecasting enables you to manage inventory levels, it also enables you to plan your workforce needs appropriately.

This is particularly important for businesses that experience seasonality, such as HVAC companies. Demand forecasting and advance scheduling are essential for effective workforce planning when weather changes and holidays cause dramatic shifts in sales.

How OptimoRoute Helps: You can use OptimoRoute to plan last mile delivery routes and schedule drivers up to five weeks in advance. Our route optimization software clearly indicates shifts that are understaffed, so you have plenty of time to find coverage or even hire additional drivers.

Helps you schedule maintenance and repairs at the best times

Without a demand forecast, it’s difficult to plan machinery maintenance or delivery-truck servicing at times that will have the least impact on your business. You don’t want to have tools out of commission at your busiest time of the year, because it slows down production, decreases your on-time delivery rate, and ties up cash when you’re likely to need it most.

Demand forecasting helps you spot peaks and valleys in demand, so you can schedule maintenance and repairs when you have less demand and these tasks are less likely to negatively impact your customers.

How OptimoRoute Helps: When it comes to last mile delivery, OptimoRoute helps you get the most out of each vehicle by accounting for individual vehicle capacity. If one truck is out of commission for repairs or maintenance, you can easily ensure that every remaining truck is operating at maximum capacity to make up the difference.

Helps manage cash flow

We’ve covered many of the ways demand forecasting reduces costs and helps mitigate expenses. And all of these cost-savings also help to protect your cash flow, or the amount of cash you have on-hand at any given time. All businesses have monthly, quarterly, and/or yearly expenses (cash going out). Demand forecasting helps you line these expenses up with sales (cash coming in) so you always have a healthy cash flow.

How OptimoRoute Helps: You can also use demand forecasts to scale up or down on software subscriptions such as OptimoRoute as demand fluctuates. OptimoRoute’s flexible pricing makes it easy to choose precisely the level of service you need from month to month.

How to Conduct Demand Forecasting

Demand forecasting consists of three phases.

1. Define your prediction parameters

Select your products and define the period of time you want to predict demand for. Typically, your parameters will be dictated by a particular goal; for example, maybe you need to gauge short-term demand to decide how large your upcoming replenishment order should be. You could use long-term forecasting to help determine how much safety stock you should have on hand an any given time throughout the year.

2. Collect data

Gather any and all information at your disposal related to potential sales, including historical sales charts, market trends, and current events insights:

- Look at historical internal sales data to determine what your sales trends have been in the past. The farther back you can go, the better.

- Keep an eye on your competition. If Apple, for instance, launches a new iPhone, it’s likely to diminish sales for competitors like Samsung unless Samsung also releases a new product at the same time.

- If you have data on how your own product launches have affected sales of your other products in the past, gather those, too.

- Compile market research and trend analyses related to your industry.

The suggestions above are not a complete list. The key is to gather as much relevant information as you can for your specific business.

3. Analyze and assess

Now it’s time for the fun part. Analyze all of the information you’ve gathered to predict what your demand will be within your defined period.

Let’s say you own a greeting-card business. You’re conducting demand forecasting for your entire product line for Q4 of 2020. You have historical sales data for the last five years. Your sales have increased at an average rate of 200 cards year over year (YoY), but as much as 250 YoY. Your Q4 sales last year were 1,400 cards. So it would be safe to estimate that your demand this year will be approximately 1,600 to 1,650 cards.

However, you also know that COVID-19-related shutdowns have caused an unprecedented spike in greeting-card sales in 2020. So you compare 2020 sales for Q2 and Q3 to the same period last year. You see that you sold 2X as many cards in 2020 compared to 2019. So you adjust your demand forecast to 2X what you sold in Q4 of last year (2,800 cards).

As you can see, demand forecasting is not an exact science. And the best types of demand forecasting vary from industry to industry. Qualitative demand forecasting methods rely more heavily on market trend and competitor analyses. Quantitative methods, on the other hand, rely more heavily on precise measurements (sales records and numeric data points). Many businesses get the best forecast accuracy when they combine these two methodologies.

Demand Forecasting Software

Here are three software options you can use to automate demand forecasting processes and get the answers you need faster.

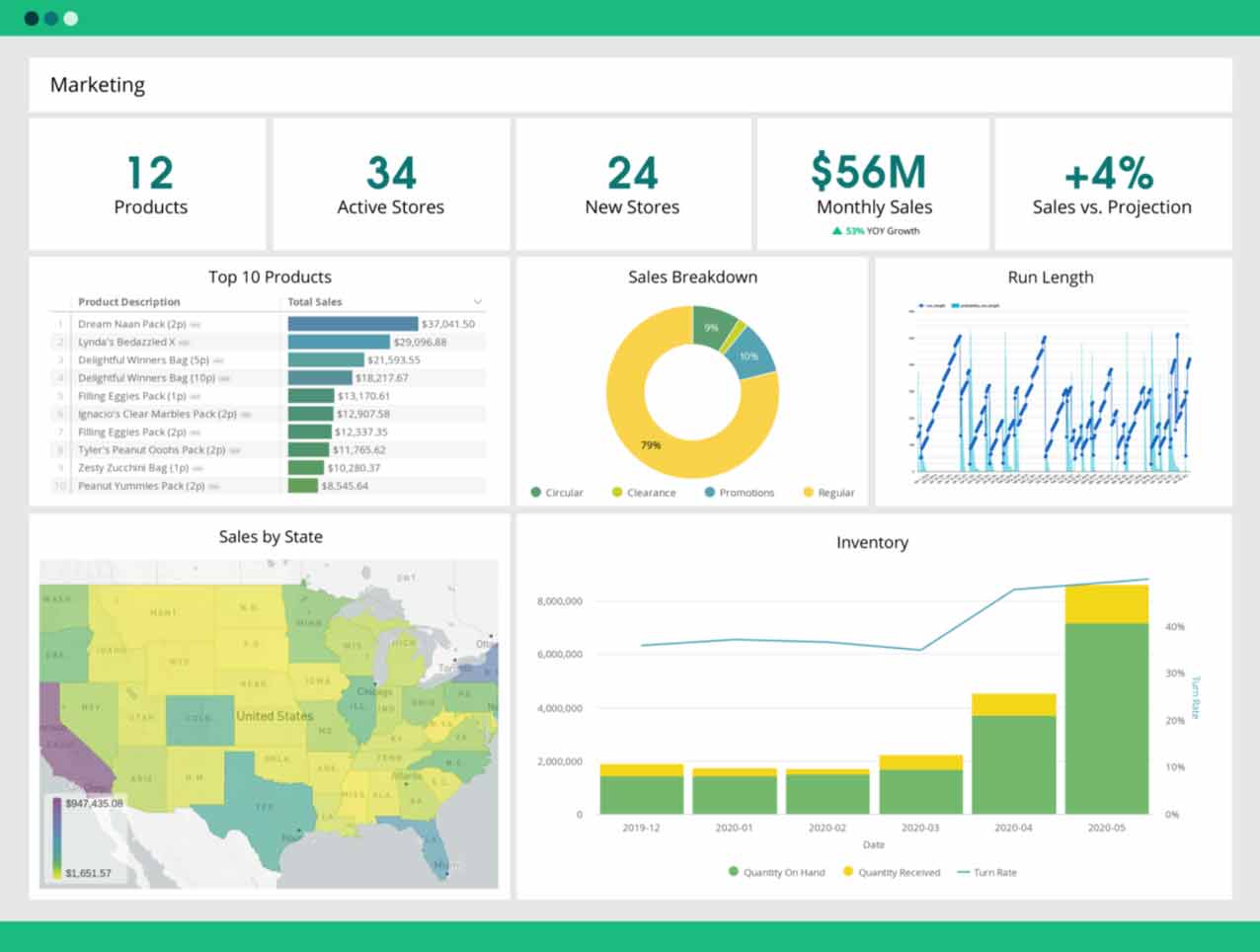

- Crisp uses AI, machine learning, and real-time supply-chain monitoring to deliver powerful analytics. Crisp makes demand forecasting easy and helps you understand what drives your demand, so you can create better sales and marketing initiatives and even refine your inventory management strategies.

- Avercast boasts more than 200 demand forecasting formulas, so you can estimate demand for as many or as few of your products as you want to— within whatever timeframe you desire. Avercast is a great choice for international businesses because it automatically calculates unit conversions and simplifies cross-cultural logistics management.

- SAFIO Solutions is demand planning software that helps with forecasting and analysis. SAFIO Solutions delivers easy to understand reports and analytics that business leaders can use to make informed strategic decisions.

Use API integrations to connect your demand forecasting software, warehouse management system (WMS), and route optimization software—and get better visibility across your supply chain.

Your Predictions Were Wrong: Now What?

Unfortunately, all of the historical data and market analysis in the world can’t guarantee that your demand forecasts will be accurate every time. So how do you protect your business in the event that there’s, say, a global pandemic, and customer demands suddenly shift in an unforeseeable way? You ensure that your systems are agile so you can respond quickly.

Adopt software that enables you to adapt quickly

Make sure your business can pivot quickly when demand shifts. Automate time-consuming processes and inventory-management tasks with a WMS such as Fishbowl and route optimization software such as OptimoRoute.

Fishbowl makes it easy to send new work orders and stock replenishment requests by tracking your inventory and saving templates for quick reordering. OptimoRoute’s dynamic replanning makes it easy to reroute drivers, and adding more orders, trucks, drivers, and deliveries takes a fraction of the time compared with manual planning.

Keep your customers in the know with updates in real time

The most important thing to do when your demand forecasts are off is to keep your customers updated. Consumers are likely to be more forgiving about delays if you notify them right away.

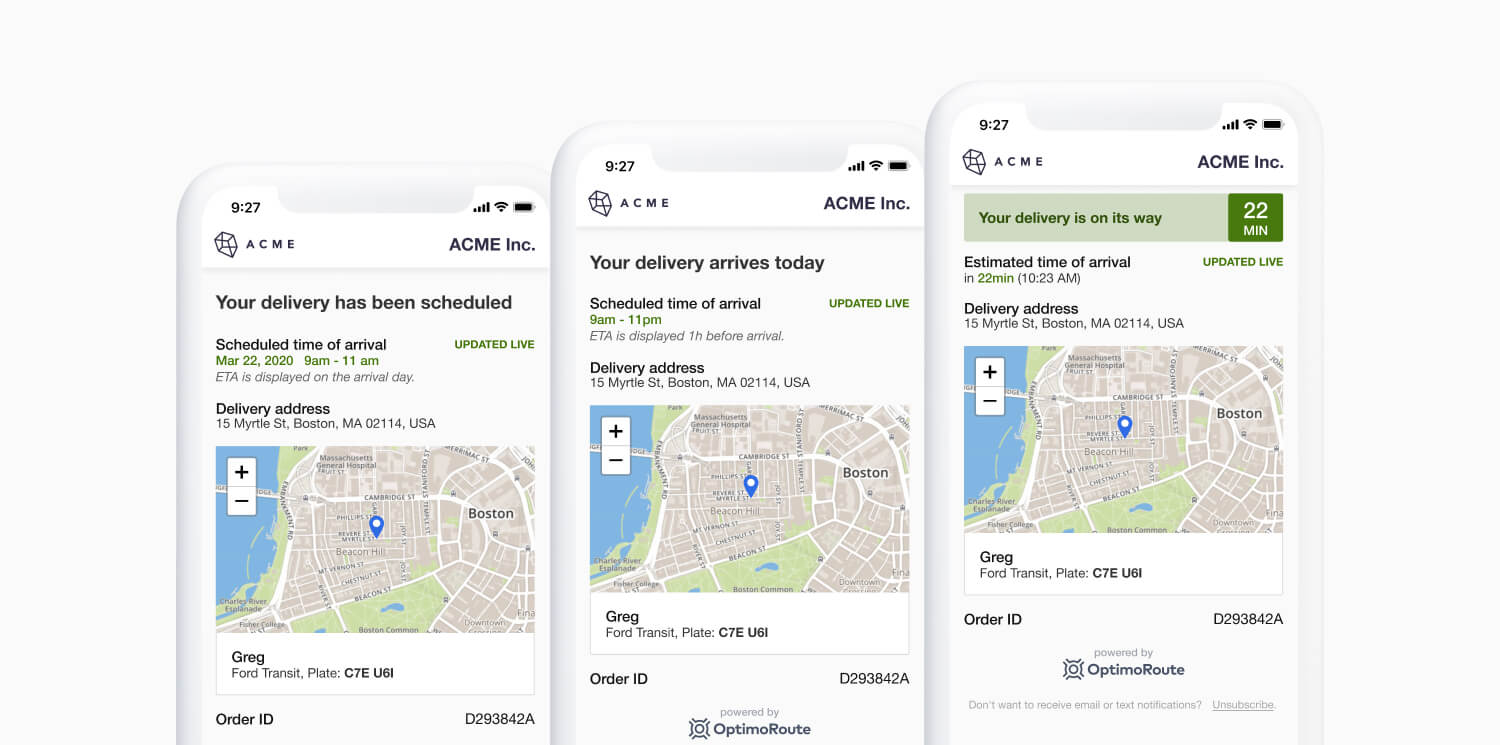

If one of your products is on backorder, make sure it’s clearly indicated on your website before customers make a purchase. And provide an estimate of when that product will be back in stock. Once your customer does make a purchase, send them a Realtime Order Tracking link so they know precisely when to expect their delivery.

If you have an in-house delivery team, you can use OptimoRoute to automatically send live tracking updates to your customers when their order is on its way. Simply customize your messaging, and set notifications to go out when a package is out for delivery, is nearing its destination, and has been dropped off. Not only does this boost your overall customer experience, but this feature has reduced incoming customer service calls for OptimoRoute clients by as much as 70%.

Try OptimoRoute Free for 30 Days

At OptimoRoute, we’ve helped hundreds of product and service businesses streamline operations to keep up with shifting demand. See what last mile delivery agility can do for your business. Start a 30-day free trial of OptimoRoute today.

Try OptimoRoute™ for Free

No installation or credit card required