Types of Capacity Planning & How It Keeps Your Products Stocked and Customers Happy

In an ever-changing world, it might feel like you need a crystal ball to plan for your company’s future. How could you know how much product you’ll need to order in three months, six months, or a year if orders haven’t come in yet? How do you adapt to evolving customer expectations? Or scale your business fast to avoid stock-outs if a surge of orders comes in?

The answers to these questions are simpler than you might think. Successful businesses of all types use capacity planning to answer similar questions every day.

What Is Capacity Planning?

Capacity planning is a type of production planning that involves determining production capacity and workforce needs to make sure your supply chain is equipped to meet demand. Capacity planning lets businesses know how and when to scale, identify bottlenecks, create better design capacity, and mitigate risk, within a planned period of time.

The 3 Types of Capacity Planning

The three types of capacity planning make sure you have enough, but not too much, of three major resources for both the long- and short-term. You’ll want to plan weeks, months, or even a year in advance.

1. Product capacity planning

A product capacity plan ensures you have enough products or ingredients for your deliverables. For a florist, this would be flowers, vases, and cards. For a pool maintenance company, this would be things like chlorine that are required to do the job.

2. Workforce capacity planning

Workforce capacity planning ensures you have enough team members and work hours available to complete jobs. This type of planning will also help you communicate overall business, resource & manpower needs to relevant stakeholders, show you when you need to hire more employees and help you determine how far in advance you need to start recruiting based on the length of your onboarding process.

3. Tool capacity planning

Tool capacity planning ensures you have enough tools to complete jobs. This includes any trucks, assembly line components, or machinery you need to manufacture and deliver your product.

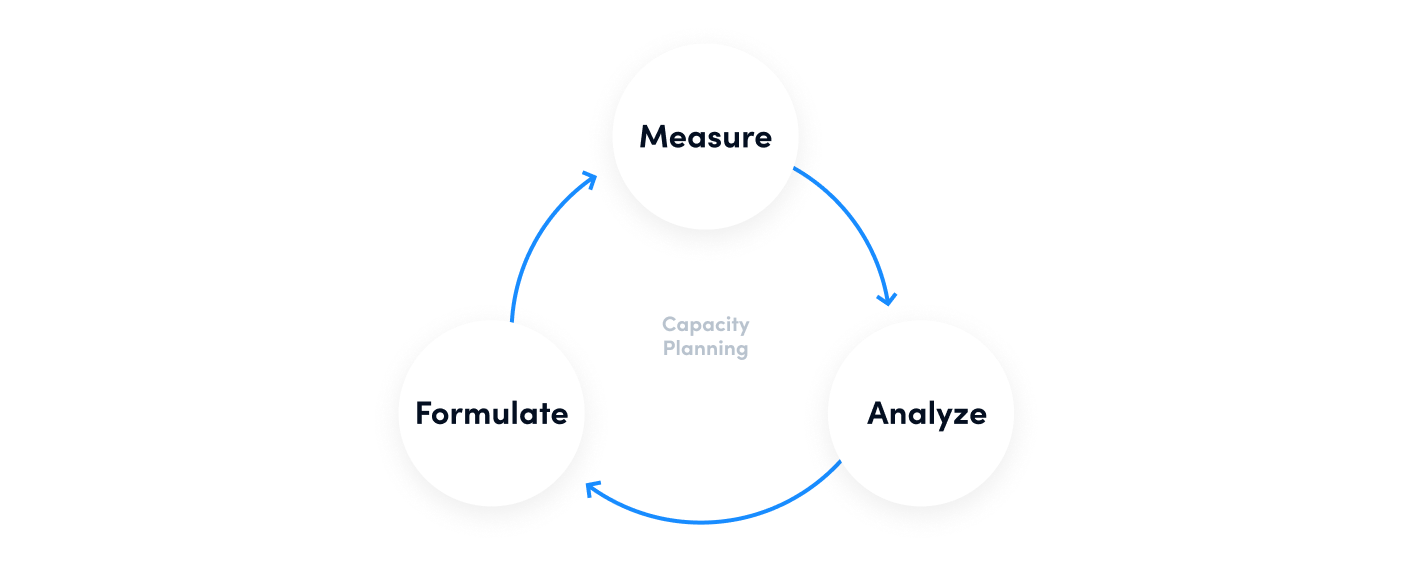

How to Start Capacity Planning

There are three basic steps to capacity planning.

1. Measure

First, you’ll need to measure your resource capacity. How many deliveries can each of your drivers make in a given period? How many orders can fit onto each of your trucks? How many hours does it take your fleet manager to plan 50 deliveries? It’s important to answer these types of questions as accurately as possible because the rest of your plan will be based on these numbers.

2. Analyze

Once you have accurate measurements, you can spend time analyzing this information and determining whether or not you have insufficient capacity or excess capacity, or if you’re fully utilizing all available resources. Making graphs will help you understand the numbers and make demand forecasting easier.

3. Formulate

The final step is taking all of the information you’ve gathered and formulating a plan. You can make calculations to see how much it will cost to fund new projects or hire a full-time employee vs. bringing on seasonal part-time workers. You could also calculate the ROI for upgrading a piece of machinery or adding assembly lines to your production facilities. The formulation stage helps you see what the likely outcomes are for various options, so you can make the best decision.

How Is Capacity Planning Different From Resource Planning?

Resource and capacity planning sometimes get confused with one another, but they are different things – and you need both. Capacity planning is more high level and helps you determine what and how many resources you need to meet demand. Resource planning is more about analyzing resource utilization: you use it to takes the number of resources available (as determined by your capacity planning) and allocate them to individual projects.

For example, let’s say you run a flower shop like The Little Posy Co., and Valentine’s Day is your busiest time of the year. You would use capacity planning to determine if you need to hire more employees, bring on seasonal workers, or increase your stock of flowers before February 14. Once you’ve determined how many workers and how much stock you’ll have in February, you would use resource planning to allocate those resources. So, if most of your demand is for vases of red and pink posies, you could allocate the largest portion of your resources to creating those floral arrangements.

Reduce your operational costs by 30%

Increase delivery capacity by 43%

Plan 7x faster

3 Strategies for Using Capacity Planning

There are three methodologies behind capacity planning. In order to choose the right strategy, you’ll need to consider the type of business you run, the level of risk you can safely assume, and the lifecycle of your products.

1. Lag strategy

Lag strategy is planning to have enough resources to meet true demand (not projected). Lag strategy is a conservative method of capacity planning that ensures your costs are as low as possible. The potential downside to this strategy is that it can create a lag in the delivery of products or services to customers, which is where the name comes from. If you get a sudden surge in orders or land a large new client who wants fast turnaround times, lag strategy may prevent you from meeting due dates.

2. Lead strategy

Lead strategy is planning to have enough resources to meet your demand forecasts. Lead strategy assumes more risk than lag strategy. For example, if you hire new workers and don’t wind up with the orders you were predicting, you could lose money paying employees to sit around. The major benefit of this strategy is that if you do have a sudden uptick in orders, you will most likely be able to keep all of your customers happy and meet due dates.

3. Match strategy

Match strategy is the middle ground between lag and lead strategy. Using match strategy, you do strategic capacity planning more frequently. You closely monitor true demand, projected demand, and market shifts/trends. Based on this information, you adjust your capacity management to meet demand in increments. This strategy offers the most flexibility with less risk than lead strategy, but it has more ability to scale than lag strategy.

The Benefits of Capacity Planning for Modern Business

The goal of capacity planning is to ensure that your supply chain is always ready and able to meet demand. Incorporating this type of strategic planning into your process will help you meet due dates, effectively scale your business, and increase your bottom line.

☑ Reduces stock-outs

Customers don’t like to wait, and if they don’t have to, they won’t. The internet has made it easy for consumers to find products somewhere else if you’re out of stock, so you need to reduce stock-outs if you want to minimize customer churn.

You could lose a third of your potential sales for an item if it’s out of stock and, worse yet, that customer may never come back.

In 2004, the Harvard Business Review published the results of a global study where they assessed the behaviors of more than 71,000 customers faced with stock-outs. Depending on the retail category, 21% to 43% of consumers went to another store to purchase an item if it was out of stock. You could lose a third of your potential sales for an item if it’s out of stock and, worse yet, that customer may never come back.

Capacity planning can help you avoid stock-outs and improve profitability. And the more you do it, the better you will understand your unique demand. The capacity planning process will help you see how demand fluctuates during different seasons (such as holidays) or how it is affected by events (like kids going back to school). You’ll be able to use this insight as a guide for overall decision making and supply chain management.

☑ Increases delivery capacity

McKinsey and Company published a 104-page compendium that illustrates the importance of delivery capacity in your retail distribution strategy. Shoppers not only want to be able to have products and food delivered to their door; they want quick turnaround times, which means your delivery process needs to be operating at maximum efficiency. McKinsey’s report explains that e-commerce has made up more than 40% of retail sales growth in the United States since 2016, and it isn’t showing any signs of slowing down.

As online sales grow ever more popular, delivery capacity is becoming an essential component for many businesses. In another global consumer study conducted by Oracle Retail, 92% of retail shoppers said they would like or love “free one-day delivery by whatever means is most expedient.” Capacity planning ensures you have the workers available to deliver products whenever needed, keeping your business competitive.

☑ Identifies process inefficiencies

When you start capacity planning, you have to ask, “what is the maximum capacity of this resource?” It’s easy to lose sight of these limitations in real-time when you’re struggling to patch together a supply chain. By taking a moment to assess available capacity and capacity requirements, you’ll gain insight into what factors limit capacity, and you’ll be able to easily spot bottlenecks that can be fixed or improved.

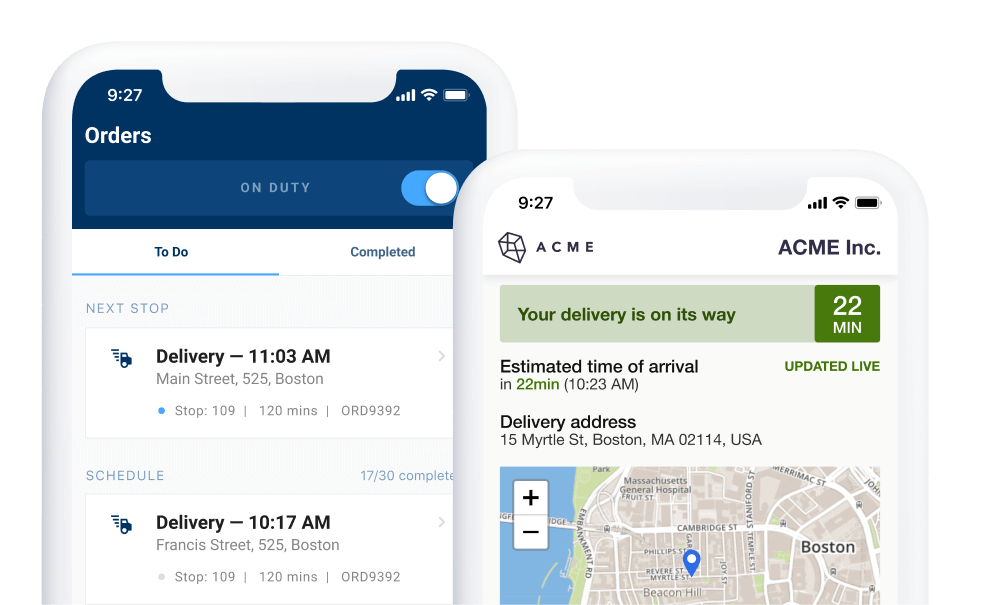

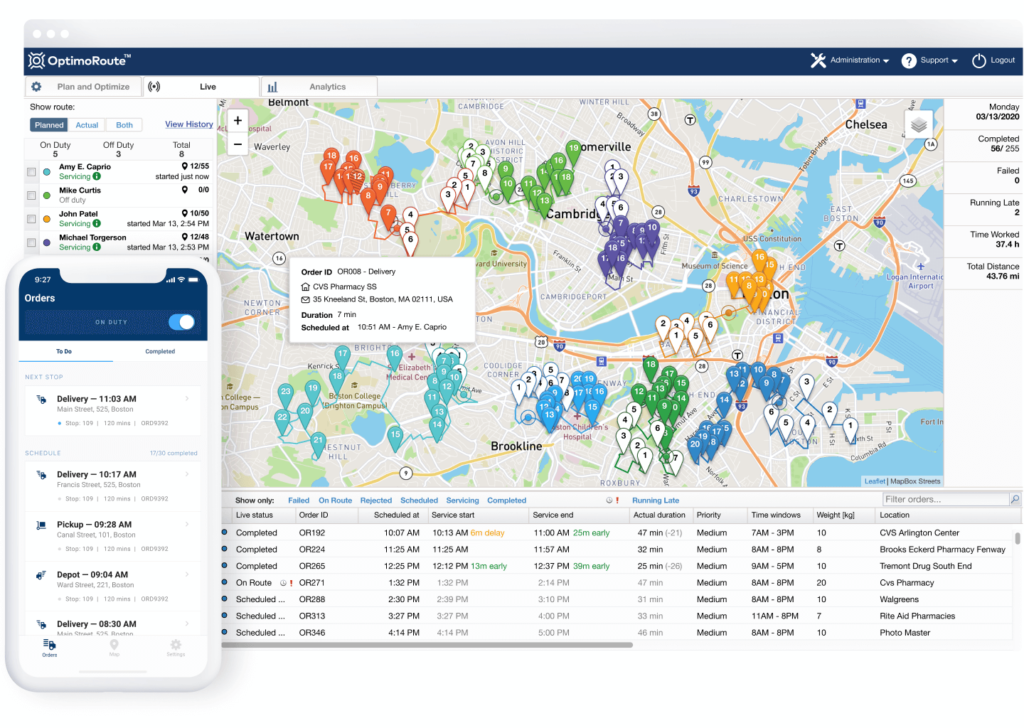

For example, let’s say you run a delivery business. Capacity planning reveals that the amount of time it takes your fleet manager to plan routes is preventing your business from being able to take on more deliveries. You realize that even though you have the trucks, drivers, and products to deliver more orders, your fleet manager requires a lot of lead time in order to effectively plan routes for new orders. You could use this insight to replace your manual planning system with route optimization software. In fact, one of our clients doubled their scheduling capacity by doing just that.

Southern Star is in charge of transporting natural gas to seven states in the U.S. In a single week, Southern Star’s 250 technicians can perform up to 2,500 maintenance activities on pipelines that span 5,800 miles. Capacity planning helped Southern Star spot inefficiencies in their scheduling process. As a result, they started using OptimoRoute, and now they are able to fit 100% more tasks into pipeline maintenance and service schedules.

☑ Facilitates risk management

At its core, effective capacity planning is a roadmap for your business. Both short- and long-term capacity planning help businesses understand their strengths, weaknesses, and limitations. You’ll be able to make informed decisions about how fast you should scale your business, when is the best time frame to launch a new product, and when you need to hire new employees.

Capacity planning will better prepare you to overcome obstacles, too. No matter how much planning you do, you’ll still need to be able to respond quickly when unexpected challenges arise. If your supplier suddenly goes out of business or three of your 10 drivers come down with the flu, you’ll need to have high-level plans in place to use as a guide, so you can make smart adjustments quickly.

Capacity, Route Planning, and Scheduling: An Efficient Trifecta

Once you’ve got your high-level (capacity) plan in place, you can use it as a guide for scheduling and route planning. You’ll want to use all three together to achieve the highest level of logistical efficiency.

We are here to help with all three. From high-level planning to managing drivers in the field, route optimization software can help you refine your delivery process and increase overall efficiency. OptimoRoute enables businesses to do delivery and route capacity planning up to five weeks at a time. You’ll be able to easily adjust the number of drivers, orders, and constraints to see where you can save money or take on more orders.

Learn more about scheduling and route planning in the deep-dive articles on these subjects on the OptimoRoute blog.

Try OptimoRoute™ for Free

No installation or credit card required