How to Use Safety Stock to Protect Your Bottom Line

6 min read

Stockouts hurt your bottom line—and lost sales are only part of the problem.

When consumers see an “out of stock“ notification on your ecommerce site or in your store, they begin to lose trust in your brand. If this happens too many times, your customers will take their business somewhere else—permanently.

Safety stock is a failsafe that protects your bottom line by mitigating your risk of stockouts. It’s a sort of inventory management insurance policy that gives you some breathing room if your supplier is slower than normal delivering replenishment or your customer demand rises unexpectedly.

Read on to learn:

- What Is Safety Stock?

- How Do Stockouts Hurt Your Bottom Line?

- How to Calculate Safety Stock

- More Ways to Reduce Stockouts

What Is Safety Stock?

Safety stock, sometimes referred to as buffer stock, is a backup supply of products or raw materials. It’s extra inventory beyond what you predict you will need within a certain time frame. Safety stock covers your business in case your demand forecasts are off or your supplier is slow sending a new batch of products.

Businesses may use safety stock for:

- Popular items that drive a large portion of sales and profits (their biggest hits)

- Items with a long lead time (it takes a long time to procure them from a manufacturer or supplier)

- Products that are at high risk of procurement delays (international shipments, etc.)

The biggest advantage of safety stock is that it reduces your risk of stockouts.

How Do Stockouts Hurt Your Bottom Line?

Stockouts are products that are out of stock or not currently available in your warehouse—meaning that when an order is placed by a customer, that order can’t be shipped out right away. Stockouts are bad news for three reasons:

1. Stockouts drive up your expenses.

When a stockout happens, many businesses place a rush order to restock inventory faster than normal. But rush orders come with extra fees. That means you’re paying more for inventory, but you’re not charging the customer more, so your profit margin on each item is reduced.

Stockouts also drive up your workforce expenses. Say, for instance, a customer purchases three items from your ecommerce store, but one is out of stock. Your last mile delivery team now needs to make two separate trips to that customer’s address—one to deliver the two items that are in stock now, and one later to deliver the out-of-stock item when your replenishment comes. These two separate deliveries also require twice the amount of packaging and create more work for your warehouse team.

How much do these extra expenses add up to? One study found that “reducing stockouts and overstocks can lower inventory costs by 10%.”

2. Stockouts hurt your customer experience (and cost you sales).

You don’t want your customers to associate your brand with the feeling of disappointment that inevitably comes from stockouts. It kills your customer experience—and your revenue.

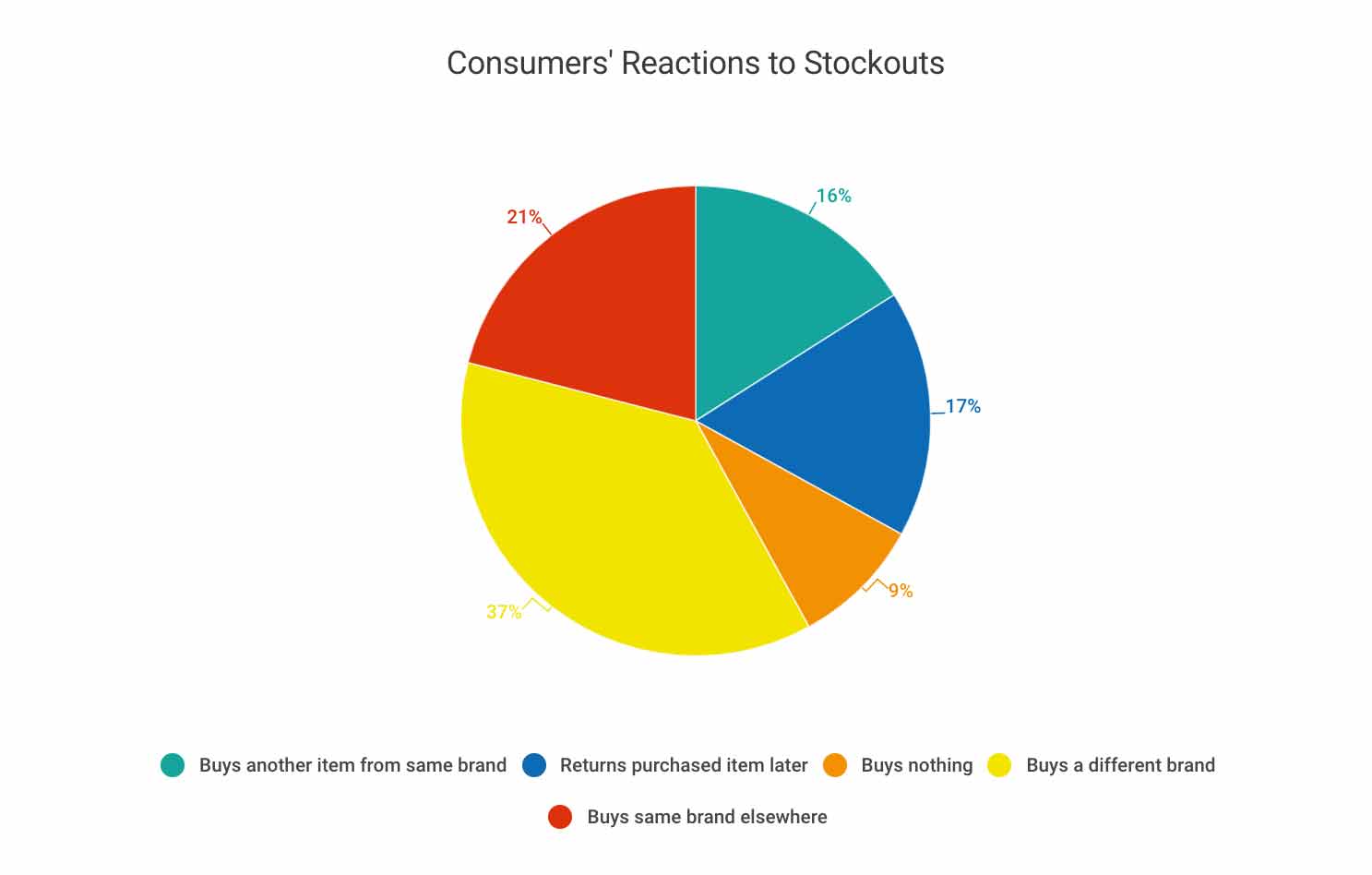

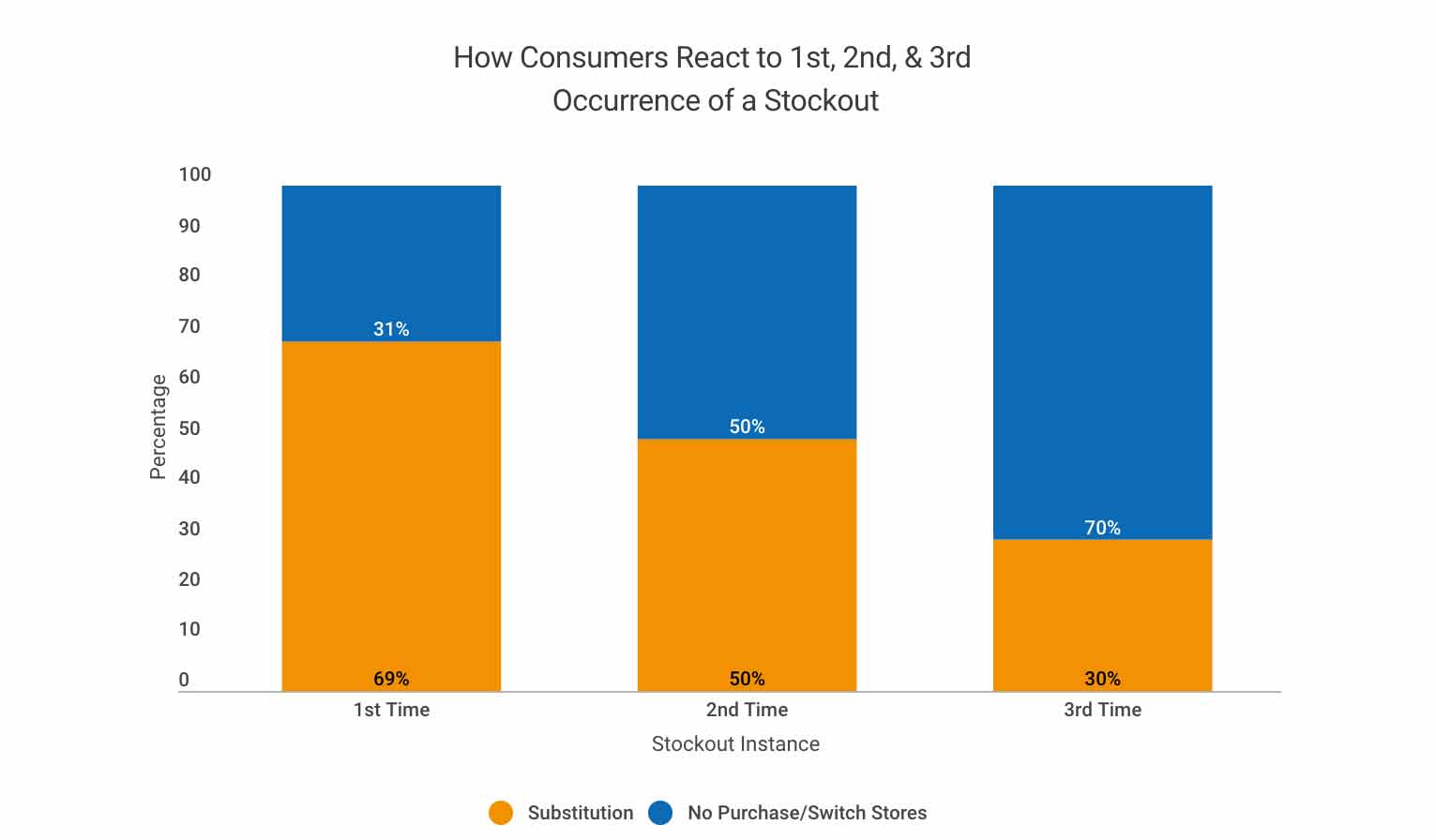

Consumer behavior research has shown that “consumers exposed to a stockout are substantially less likely to return to the same store on their next shopping trip.” When confronted with a stockout, 30% of consumers will either abandon their purchase or go somewhere else to buy the item they were going to purchase from you.

The second time this happens, you lose 50% of your customers, and the third time that number rises to 70%.

Unfortunately, consumers aren’t very forgiving when it comes to stockouts. So, unless you sell a product that is truly one of a kind, and customers simply can’t get it anywhere else, you need to work very hard to maintain your inventory levels.

3. Stockouts cause ripple effects in your entire stock inventory.

Stockouts have negative ripple effects across your entire inventory. Because while 30% of consumers won’t make a purchase from your store at all, 53% will substitute the item they were going to purchase with a different SKU (based on the pie chart above, 37% buy an item from a different brand, and 16% buy a different item from the same brand). When this happens, it can cause unexpected spikes in demand for additional products—or rippling stockouts.

Say, for instance, that you own a grocery store. Due to a delay with one of your suppliers, you run out of red bell peppers. So 53% of your consumers who wanted to buy red bell peppers purchase orange bell peppers instead—which causes an unplanned-for spike in orange bell pepper sales. As a result, you run out of orange bell peppers. Now, 53% of customers who come into your store intending to buy both red and orange bell peppers buy yellow bell peppers instead, and you quickly run out of those, too.

This is how one stockout can snowball into an entire category stockout (and a big problem for your inventory management team).

How to Calculate Safety Stock

Since safety stock is designed to protect your business from unforeseen circumstances, there are many complex methods for calculating safety stock. Here are three of the most popular formulas:

1. The max – average formula

There are four factors you need to know before you can use this equation to calculate safety stock:

- Maximum units sold daily

- Maximum lead time

- Average units sold daily

- Average lead time

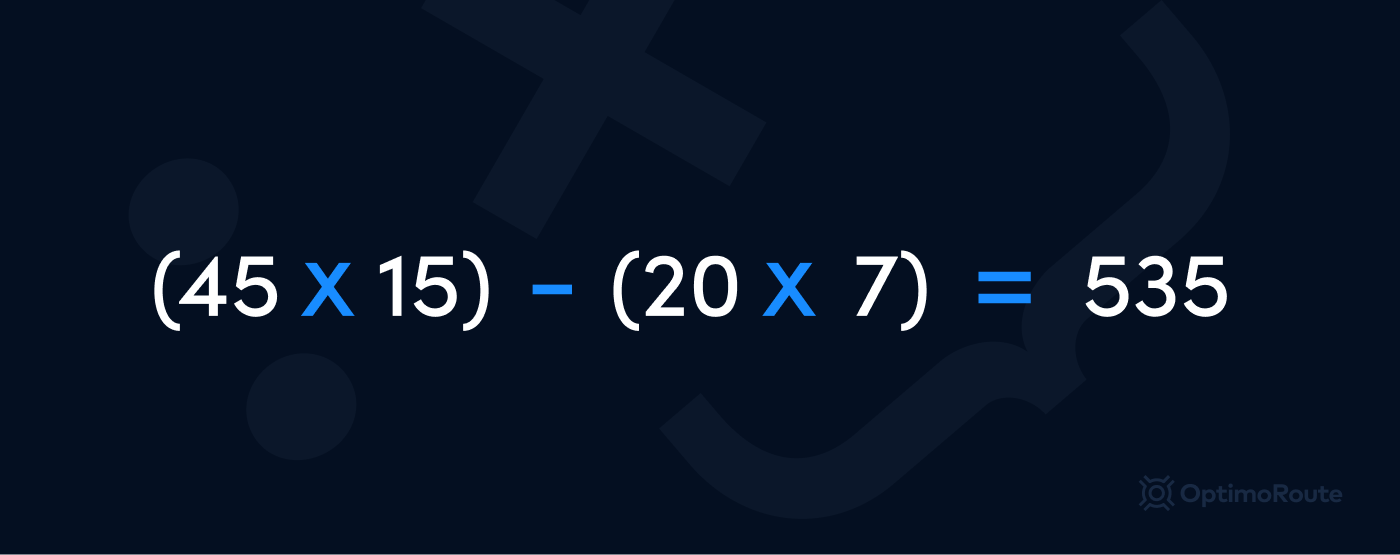

Say you’re a fashion-accessories retailer, and baseball caps are your most popular item. You average 20 sales per day, but last year you sold as many as 45 in one day. Your average lead time (the amount of time it takes for you to receive new caps from your manufacturer after you place an order) is seven days. But COVID-19-related shipping delays have caused longer lead times—as much as 15 days.

To determine how much safety stock of baseball caps you should have on hand, multiply 45 (your maximum number of units sold in one day) by 15 (your maximum lead time in days) to get 675. Then, multiply 20 (your average number of sales per day) by 7 (your average lead time) to get 140. Finally, subtract 140 from 675 to get 535 units.

The problem with this formula is that it doesn’t account for seasonality. So if your maximum lead time or maximum daily sales differ drastically from your averages, your safety stock calculation will be unnecessarily high. And if your safety stock levels are too high, you’ll overpay for holding costs.

Say, for instance, you own a flower shop, and, on average, you sell 10 dozen red roses. The most red roses you sell in one day from March through December is 15 dozen. If your supplier is super reliable, and your lead time is a consistent five days, this would mean the level of extra stock you should have at any given time is 25 dozen.

But your flower shop sees a steep uptick in demand (5x your normal daily average) leading up to Valentine’s day. If you use the same equation but base it on a full year of sales, your safety stock jumps up to just over 158 dozen—which may be necessary for a couple of weeks leading up to Valentine’s Day, but it’s way too much for the rest of the year. So the period you use for your calculations is very important.

2. The basic safety stock formula

Another formula for safety stock is to simply multiply your average daily sales for an item by the number of days you want to have a reserve for.

Taking the same accessories company example from above, if you sell an average of 20 hats per day and you want enough safety stock to cover you for one week of average demand, simply multiply 20 by 7 to get 140. This simplified formula is a great place to start, especially if you’re a small business with a limited product line.

3. Formula variations

Calculating safety stock can be a confusing endeavor, and it isn’t a one-size-fits-all formula. Myriad safety stock formulas exist, and new approaches are being thought of all the time. Think of safety stock as more of a work in progress than something you achieve and move on from.

These resources provide more safety stock formulas for an array of applications:

- Safety Stock Formulas and Safety Stock Calculation-The Ultimate Guide

- A New Safety Stock Formula – Part 1

- Inventory Parts Planning

Manufacturing consultant Michael Baudin wrote, “No calculation or simulation, however, is a substitute for keeping an eye on what actually happens on the shop floor during production.” The important thing is to consider your unique business model, supply chain, and objectives when placing orders for safety stock.

More Ways to Reduce Stockouts

Safety stock is just one tool available in your arsenal for avoiding stockouts and keeping your customers happy. Check out these OptimoRoute articles for more strategies, tips, and tricks to reduce stockouts, protect your profits, and streamline your supply chain logistics:

- How Logistics Scheduling Keeps Everything on Track (and How to Simplify It)

- What Is Capacity Planning?

- Distribution Center Processes and Practices You Need to Know

- Warehouse Management: Definition, Challenges, and Why It’s Crucial for Business

- Why & How to Improve Process Efficiency in Your Business

- Warehouse Layout + Route Optimization Software: The Essential Tools for On-Time Deliveries

Try OptimoRoute™ for Free

No installation or credit card required