Warehouse Terminology Cheat Sheet: Essential Warehouse Vocabulary and Acronyms

11 min read

When you start a new job, there’s a lot to learn. And warehouse jobs come with an extra challenge: learning what seems like a whole new language.

So we compiled a handy cheat sheet of warehouse vocabulary to make settling in easier. You’ll find links to additional resources to level-up your know-how even further, too.

Skip ahead to chapters in this article:

Warehouse Terminology, Initialisms, and Acronyms

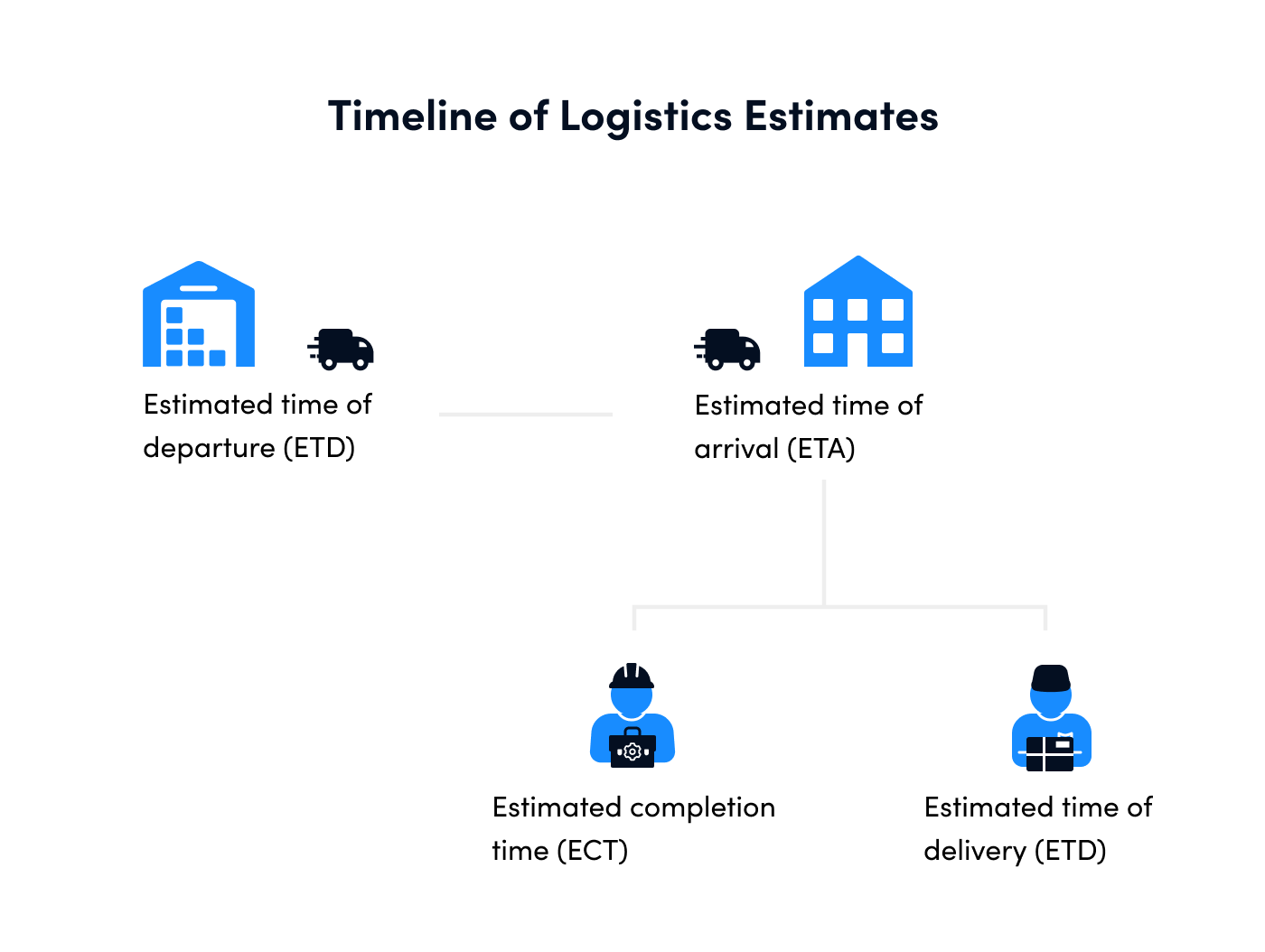

Words and acronyms can have different meanings. “ETD,” for instance, may stand for estimated time of delivery or estimated time of departure— two very different things. So don’t assume your coworker is using the same definition you are, even if yours is correct. If you have any doubts, ask. It’s also a good idea to use full terms rather than initialisms or acronyms when you’re communicating with vendors or clients to avoid any misunderstandings.

And now, here they are—the most common warehouse terms, acronyms, and phrases you’re likely to hear on the job:

3PL: Third-party logistics (see third-party logistics for definition).

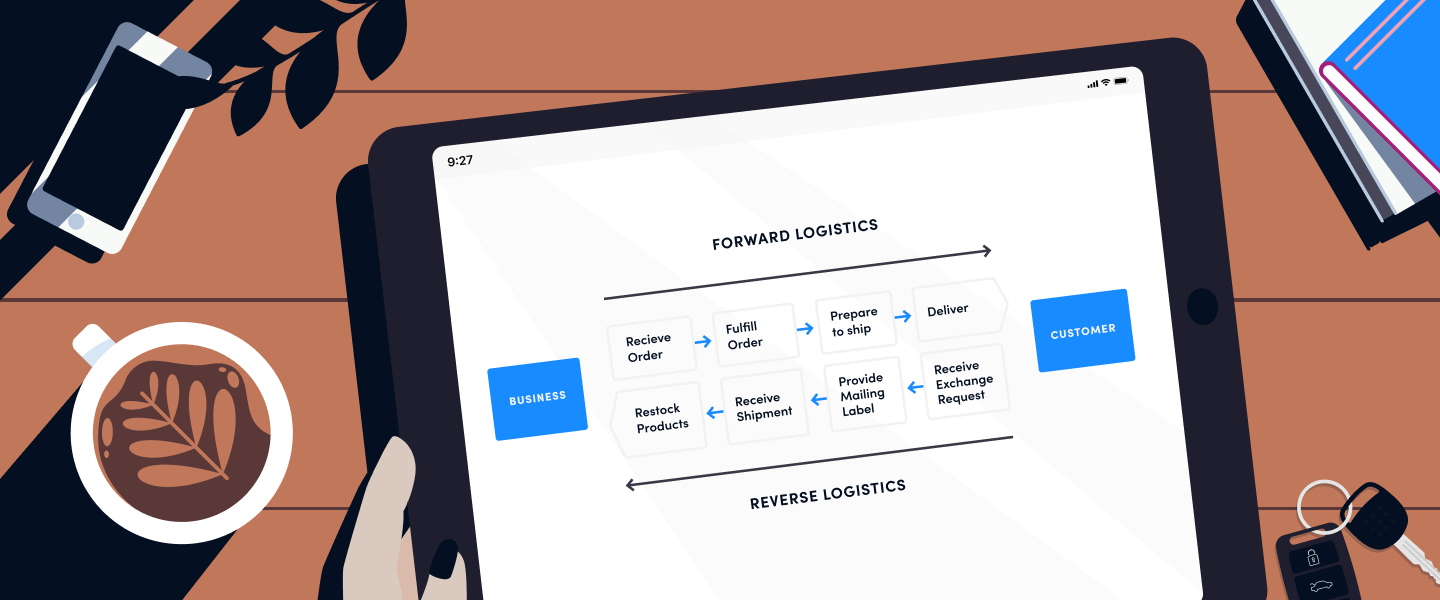

Backhaul: The process of moving goods from what was originally their final destination back to their origin point. In warehousing, backhauls can also be truckloads of goods that customers have returned or for which they have requested an exchange. An incoming backhaul will typically need to be inspected for damage and then, once approved for quality, restocked. Learn more about backhauling and reverse logistics.

Back order: A purchase order for an item that is currently out of stock. When a particularly popular item sells quickly, sometimes the warehouse runs out of stock before they get more from the supplier or manufacturer. Retailers will often continue to sell these items to consumers with a note that they are “on backorder” and will be delivered later than normal. When this happens, warehouse teams need to fulfil existing orders as soon as new stock arrives rather than first moving that inventory to storage.

Bar coding: The machine-readable identification system used to track, scan, and process inventory.

Batch picking: A picking process in which a batch of multiple customer orders containing similar items is gathered from warehouse shelves at the same time. For instance, three separate customer orders including a box of pencils could be batched so the picker needs to walk to the pencil-box storage location only one time rather than three. Learn more about warehouse picking processes.

Bill of lading(BOL): An official document detailing items contained in a shipment. The bill of lading moves with a shipment from the sender to the shipper and then to the consignee (final recipient). When a warehouse receives a shipment from a supplier, it comes with a bill of lading that processing clerks use to verify that the delivered goods match the purchase order.

BOL: Bill of lading (see bill of lading for definition).

Cantilever rack: Storage device with prongs rather than shelves that are used to store long and/or oddly shaped items. Cantilever racks may be free-standing or mounted to a wall.

Cold storage: A section of a warehouse in which refrigerated or frozen products are stored. Cold storage is most commonly found in food-grade warehouses.

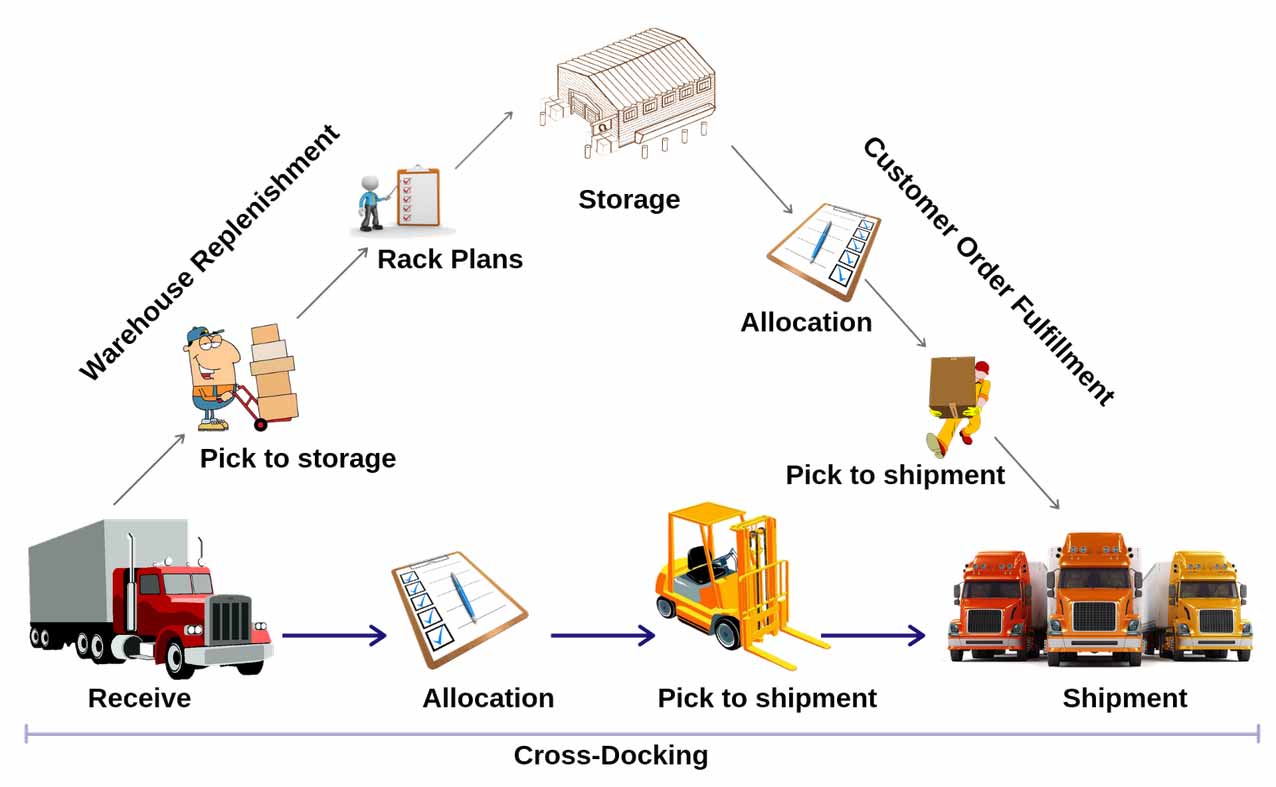

Cross-docking: A distribution process in which goods are received from a supplier and immediately sorted, packed, and shipped to a customer rather than being moved to a warehouse shelf for storage. Cross-docking is often used in warehouses to fulfill customer orders for items that were on back order.

Cycle count: An auditing process in which inventory is counted on a cyclical basis. Inventory is counted in sections on a regular basis to make auditing more manageable and ensure that inventory records are accurate. To learn more, check out our guide to warehouse auditing.

Dimensional weight (DIM): A measurement used by couriers and shipping carriers to determine the cost of sending goods. To calculate the dimensional weight of a package, you multiply the length times the width times the height.

Dispatching: The process of organizing, scheduling, and managing vehicles and drivers. Warehouses that have an in-house local delivery team often have a fleet dispatcher who coordinates packing, vehicle loading, and delivery scheduling. Learn more about fleet dispatching.

Distribution center: A facility where goods are sorted, packed, and processed for shipping to their final destination (the customers). Many warehouses are also distribution centers, meaning they not only store or warehouse goods but also offer picking, packing, and even delivery services.

Drop tailer: A truck trailer that is dropped off for loading and then picked up at a later time. Sometimes couriers will have a driver drop off an empty trailer and pick up a full one to maximize efficiency.

Dry storage: A section of a warehouse in which products are stored in a nonrefrigerated environment that is at or around 50 degrees Fahrenheit. Dry storage may still be temperature-controlled to combat extreme outdoor weather conditions.

Estimated time of arrival (ETA): The expected time a vehicle or vessel will get to its final destination. Warehouses typically receive an ETA for trucks carrying incoming stock. Warehouses may also need to provide an ETA for delivery of outgoing stock. Learn more about delivery estimates.

Estimated time of departure (ETD): The expected time a vehicle or vessel will leave its point of origin. Warehouses often use this to note when a delivery truck or courier vehicle will be completely loaded and depart a loading bay. Learn more about delivery estimates.

Estimated time of delivery (ETD): The expected time goods will be delivered. Suppliers and manufacturers may supply receiving clerks with an estimated time of delivery instead of an estimated time of arrival for incoming inventory. Learn more about delivery estimates.

ETA: Estimated time of arrival (see estimated time of arrival for definition).

ETD: May indicate “estimated time of departure” or “estimated time of delivery” (see estimated time of departure or estimated time of delivery for definition).

FIFO: First in, first out (see first in, first out for definition).

First in, first out (FIFO): An inventory management strategy based on the principle that the first items into the warehouse should be the first ones to leave. Food warehouses often employ this strategy to ensure that products expiring the soonest are the first to be shipped out.

Forward-pick location: An easily accessible storage area in which small quantities of frequently purchased items are placed. Forward pick locations are used to make picking faster when orders come in. Pickers can quickly access items in the forward pick location and then replenish that supply from a secondary location when it won’t impact customer turnaround times.

Gaylord box: A bulk shipping and storage box sized to fit on top of a pallet. Gaylord boxes are frequently used in the logistics industry to transport and easily store goods of many shapes and sizes.

JIT: Just in time (see just in time for definition).

Just in time (JIT): In warehousing, “just in time” is a supply-chain management method with which products are ordered, stored, assembled, or manufactured to fulfill an order just in time. No matter how skilled you are at calculating demand, you will run into incidents where demand exceeds your supply. Many companies store safety stock, or more stock than their predicted demand requires, to cover them when these demand surges occur. The JIT method of inventory management doesn’t use safety stock to cut down on storage costs.

Last mile delivery: The process of transporting goods from a warehouse or distribution center to their final destination (the customer). Last mile delivery refers exclusively to the final stage of the logistics supply chain (and happens after packing and vehicle loading).

Lead time: The time it takes to complete a logistics process. Lead time for final delivery, for instance, would include the time it takes for picking, packing, vehicle loading, and last mile delivery. The lead time for inventory replenishment includes the time required to fulfill a purchase order, transport goods from supplier to warehouse, inspect the shipment, and then restock that inventory.

Less than truckload (LTL): A type of freight shipping in which goods that weigh more than 150 pounds but take up less than a full truckload are transported. Shipping carriers use LTL shipping to move goods for multiple retailers in the same truckload. Each retailer pays only for the cargo space their items take up.

Lights-out warehouse: A warehouse that employs machines and automated systems to manage and move products rather than human labor.

LTL: Less than truckload (see less than truckload for definition).

Packing: Preparing purchase goods for last mile delivery. Packers put purchased items into boxes and prepare them to be loaded onto delivery vehicles.

Pallet: A flat structure, typically made out of wood, used to move goods. Pallets make is easier to move and store large items (or large quantities of items). They can be easily maneuvered with a forklift, pallet jack, or other machinery.

Pick and pack: A common way to refer to the processes of picking and packing within a warehouse (see picking and packing for definitions).

Pick list: The list of items pickers need to retrieve from warehouse shelves or storage. Customer orders are broken down into lists of purchased items or “pick lists,” which are given to pickers to retrieve.

Picking: The process of gathering or picking purchased items from warehouse shelves. When a customer makes a purchase, pickers gather those purchased items from their storage location and bring them to packers. Learn more about warehouse processes.

PO: Purchase order (see purchase order for definition).

Purchase order (PO): A request for goods sent from a buyer to a seller. Warehouses place purchase orders with suppliers and manufacturers for replenishment when stock runs low.

Put-away: The process of taking inventory from receiving and “putting it away” on shelves or storage racks. Workers may use this term to direct you to put return items on shelves as well.

Radio-frequency identification (RFID): A wireless tracking and data-transfer system. In warehousing, RFID tracking is used to monitor inventory. RFID tracking tags are placed on inventory as it comes in, and sensors throughout the warehouse are able to then track those goods as they are moved throughout the facility.

RFID: Radio-frequency identification (see radio-frequency identification for definition).

Receiving: The warehouse intake process. When goods arrive at a warehouse, they first go through receiving, where they are scanned and inspected by a receiving clerk. Learn more about warehouse processes.

Replenishment: The restocking of inventory. “Restocking” is used differently depending on which warehouse department you work in. Receiving clerks, for example, may refer to goods arriving from a supplier to fulfill a back order as replenishment. Pickers, on the other hand, often use replenishment to refer to stock that needs to be moved from a secondary location to a forward pick location.

Reverse logistics: The process of moving goods backward from what was originally their destination (typically the customer) to their origin point. Reverse logistics is used when a customer returns or exchanges an item. The process of retrieving that returned item from the customer, bringing it back to the warehouse, inspecting it for quality, and then restocking it is reverse logistics. Learn more about reverse logistics.

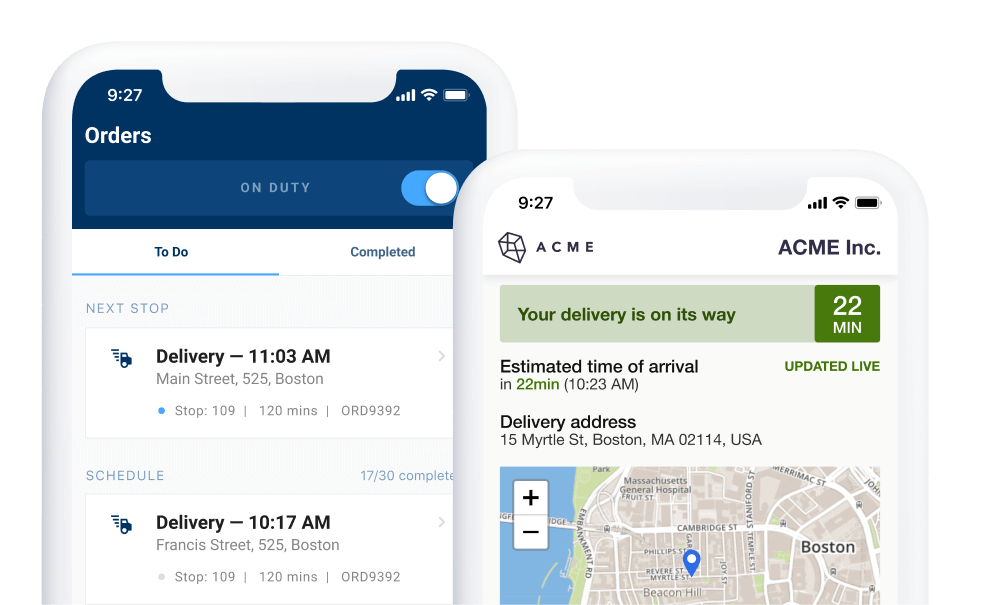

Route optimization software: Dispatch software used to simplify last mile delivery. Route optimization software, such as OptimoRoute, automatically calculates the most efficient routes for delivery teams. Many warehouses and 3PLs integrate route optimization software with the warehouse management system to give management teams end-to-end visibility across their supply chain. Learn more about route optimization software.

Reduce your operational costs by 30%

Increase delivery capacity by 43%

Plan 7x faster

Safety stock: Extra inventory kept on hand (or stored in a secondary storage location within a warehouse) to mitigate stockouts if demand rises unexpectedly or a supplier experiences delays. Safety stock is most commonly used for popular products that do not expire.

SKU: Stock-keeping unit (see stock-keeping unit for definition).

Supply chain: All of the processes used to produce and move products. A warehouse supply chain may consist of receiving, put-away, picking, packing, and vehicle loading. The full logistics supply chain includes manufacturing, warehousing, and last mile delivery. Learn more about the warehouse supply chain and material movement within your facility.

Stock-keeping unit (SKU): A barcode and/or unique identification number assigned to products by a retailer. SKUs typically consist of a scannable barcode as well as a unique numeric or alpha-numeric number. SKUs are different from UPCs because they are managed and assigned by the company selling the product, not by the Global Standards Organization. Because of this, it is possible for products from two different retailers to wind up with the same SKU. It is common for products to have both a SKU and a UPC.

Stockout: A stockout typically indicates that a warehouse has run out of inventory for a certain product, and a new purchase order has not been placed yet. Stockouts can also happen when retailers decide to stop carrying a certain product. Learn how to reduce stockouts using logistics scheduling.

Third-party logistics (3PL): A type of logistics provider that offers product transportation, management, and organizational services in addition to warehousing. A traditional warehouse is simply a space for retailers to store goods until they are purchased, but a 3PL often handles inventory management, picking, packing, and even last mile delivery. The growth of ecommerce has created more demand for 3PL’s. Learn more about third-party logistics.

Universal Product Code (UPC): The unique barcode and 12-digit number assigned to products and managed by the Global Standards Organization. Learn more about the Universal Product Code.

UPC: Universal Product Code (see Universal Product Code for definition).

WMS: Warehouse management system (see warehouse management system for definition).

Warehouse management system (WMS): Management software used by warehouse teams to track inventory and manage warehouse operations. This is the interface you’re likely to access from a scanner, an iPad, or another device while working in a warehouse. Learn more about warehouse management systems.

Zone picking: A picking process in which a team of pickers each picks products from a particular zone and then combines picked items before packing. Zone picking is often used in larger warehouses and those with clearly designated storage areas, such as cold and dry storage. Learn more about warehouse picking processes.

The Future of Warehousing

3PLs (third-party logistics companies) are the future of warehousing. If your warehouse doesn’t already offer picking, packing, and material-handling services, chances are they will soon, which is why we included the most important delivery terminology in this cheat sheet, along with more traditional warehousing terms.

As ecommerce has taken off, supply-chain demands have shifted. Warehouses are no longer a necessity solely of large corporations with massive stock quantities. Small retailers also need warehousing and, even more than that, inventory management.

While brick-and-mortar stores send large amounts of goods from a warehouse to one store location at a time, ecommerce businesses need small customer orders sent all over the globe from their warehouse. And warehouses are adapting to meet this demand by partnering with shipping couriers and even running local deliveries with an in-house team.

Bee Imagine is a great example of a 3PL that is embracing this shift in demand. Bee Imagine, a 3PL with three locations in Southern California, offers full-spectrum warehousing and logistics management. They handle fulfillment, warehousing, last mile delivery, and more—making them a one-stop shop for retailers of all sizes.

Using OptimoRoute, Bee Imagine seamlessly executes 4,000+ deliveries per month while synchronizing last mile delivery and warehouse operations. They’ve even taken full-spectrum logistics one step further by offering real-time ETA’s that their retail clients can share with consumers.

Learn More About OptimoRoute

Interested in learning more about OptimoRoute and how your warehouse can expand services with an in-house delivery team easily? Check out our blog for customer stories, product features, and examples of how other 3PLs are maintaining a competitive edge in a changing logistics world.

Plus, your warehouse can trial OptimoRoute at no cost for 30 days. Click this link to activate a free trial.

Try OptimoRoute™ for Free

No installation or credit card required