Inspection Management Software: Definition, Benefits & Best Tools [2024]

In 2019, workplace fatalities in the U.S. rose to all-time highs because inspections conducted by the Occupational Safety and Health Administration (OSHA) of America fell to record lows.

Inspections are essential to keep employees safe and operations running. One of the best ways for businesses to keep up with inspections is by using inspection management software, which helps organizations of all sizes efficiently conduct regular audits and inspections of their facilities.

In this article, we’ll break down what inspection management software does, the pros and cons with using inspection management software, and share the highest-rated inspection management software tools.

Jump to the section that’s most relevant to you:

- What Is Inspection Management Software?

- What Types of Inspection Management Software Are There?

- Pros and Cons of Using Inspection Management Software

- Why Route Optimization Matters for Inspection Management

- 3 Top Inspection Management Software Solutions

What Is Inspection Management Software?

Inspection management software is a category of digital tools—including checklists, work order management systems, and reporting and analytics dashboards—used to verify the safety of an organization’s facilities. They help organizations remain in compliance with health and safety codes prescribed by public sector authorities like OSHA.

Field inspection and field service professionals use inspection management software when they tour an office building or a corporate plant and make sure the location is safe for work. Examples include making sure a facility has an adequate number of entrances and exits that can be used in the event of a fire or an emergency and checking that fire extinguishers are located throughout the property and have gone through their annual maintenance.

What Types of Inspection Management Software Are There?

Inspection management software is a broad category and can be broken down into multiple verticals:

- Safety Inspection Software—these are general-purpose inspection tools used by field service management teams.

- Automotive Inspection Software—these are tools for vehicle and automotive inspection teams.

- Property Inspection Software—these are tools for residential and commercial inspections teams. They’re often used by property managers in conjunction with other property management software.

Pros and Cons of Using Inspection Management Software

Inspection management software helps increase employee safety, maintains a business’s productivity and compliance with government regulations, and creates digital records that help with regular maintenance. However, most tools in this category add to a business’s costs because they lack important route planning and optimization features. This leaves employees to take long and expensive routes to service locations, costing a business time and money.

Pros

- Increase Employee Safety

Teams can identify and resolve safety issues faster with inspection management software, which keeps employees safe.

Without a software tool, inspection teams use pen and paper as they tour a facility and record possible hazards in their paper reports. This often slows down the process of fixing issues on-site because paper reports need to be copied and shared with additional team members before any repair work can begin.

With software, work orders can be instantly created and assigned to technicians to be fixed. - Maintain Business Productivity

When a workplace incident or an equipment failure occurs, a facility is usually shut down.

With inspection management software, businesses can address safety hazards based on their priority. This makes sure the most serious issues are resolved first and keeps the business running smoothly. - Ensure Regulatory Compliance

As compliance needs change, it can be difficult for inspection teams to keep up to date. Inspection management software updates compliance requirements in real-time, so you don’t have to worry about new compliance needs slipping through the cracks. - Create Digital Records for Maintenance

Inspection management tools capture important information, like the seriousness of an issue or the type of repair work that may be needed, that can be used by businesses to schedule preventative maintenance and take corrective actions.

If a possible facility or equipment hazard gets flagged, inspection teams can create work orders in their maintenance management software so hazards can be quickly addressed by technicians.

Maintenance teams can analyze equipment failures or facility issues by looking at digital inspection data so those same issues don’t occur again.

Cons

- Longer Planning Times

Dispatchers can’t plan efficient routes for their inspection teams with these tools. They’re forced to plan routes manually, which takes longer and is prone to error. - Limited Service Capacity

Inspection teams are forced to travel along inefficient routes to job sites because inspection management tools don’t have route optimization features. This limits how many sites they can visit and service in a day.

With route optimization, businesses can increase the number of jobs serviced per employee by 20-30% every day.

Why Route Optimization Matters for Inspection Management

Route optimization software reduces planning time for your dispatchers, saves time for your inspection teams in the field, and increases their service capacities.

Take the case of Telgian, a worldwide provider of fire, life safety, and security services. The company is based in Phoenix, Arizona, and it manages a distributed team of inspectors. OptimoRoute’s route planning and optimization software enabled it to become more efficient and grow its service capacities by 20% annually.

Reduced Planning Times

Before using OptimoRoute, Telgian had a team of three dispatchers routing their inspectors across the country. Planning was manually done, and it took this team three weeks to plan all their routes.

After moving to OptimoRoute, Telgian was able to reduce its dispatcher team from three people to one person and reduce planning time from three weeks to one week. In total, that was a reduction of 312 man-hours to 56 man-hours for planning their routes.

Increased Service Levels

Telgian provided around 3,000 inspections a month before they used route planning software. Since they were planning routes manually, their routes were inefficient, and their inspectors were losing valuable time in the field.

After moving to OptimoRoute, Telgian was able to grow its service capacities to 5,000 inspections a month in three years. Moving to route optimization software allowed Telgian to take on nearly 70% more orders than before.

When you look at the numbers, the math is pretty simple—route optimization software reduces your planning costs and grows your revenues by increasing your service levels.

3 Top Inspection Management Software Solutions

If you’re in the market for an inspection management software solution, these three options offer best-in-class custom checklists, scheduling features, and reporting and analytics for your inspection needs. They also offer iOS and Android mobile apps for inspectors to log hazards and conduct inspections from their mobile devices offline.

iAuditor

iAuditor is a 2021 Capterra Top Performer and has a 4.6 rating out of 170 reviews. It’s used by both family-run businesses like Burt Brothers Tire & Mechanic and large enterprise organizations like Schneider Electric. In addition to features like checklists and reporting, it offers businesses the ability to automate workflows so they can create standard inspection processes.

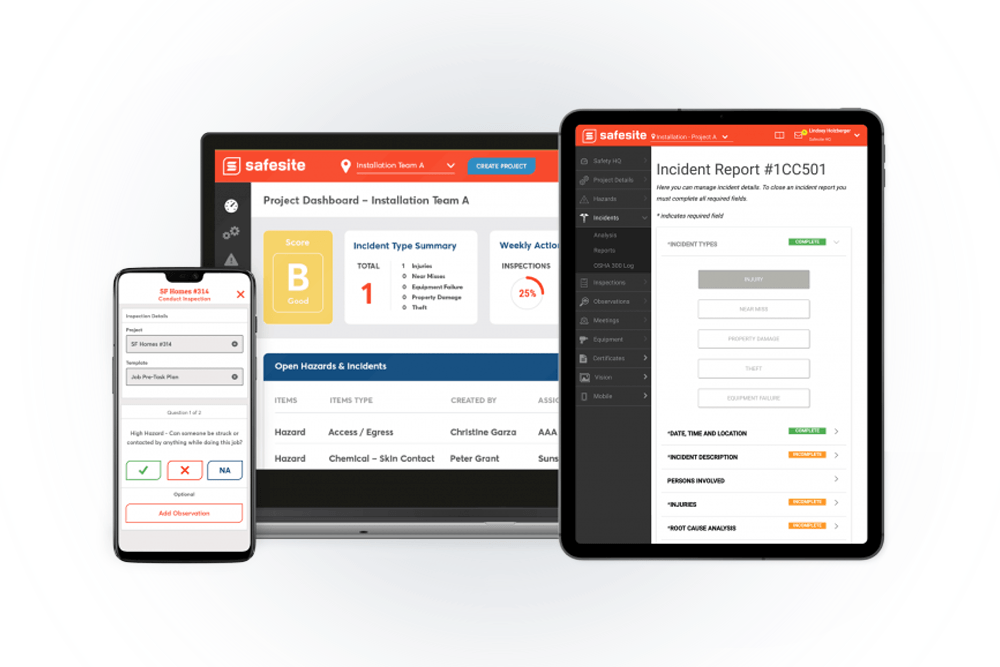

SafeSite

SafeSite is an inspection management software tool with a team based in the U.S. It’s also a 2021 Capterra Top Performer with a 4.7 rating out of 73 reviews. It offers inspection templates for a range of different industries like agriculture and manufacturing. It also offers a team of dedicated compliance professionals who are available on-call for your business.

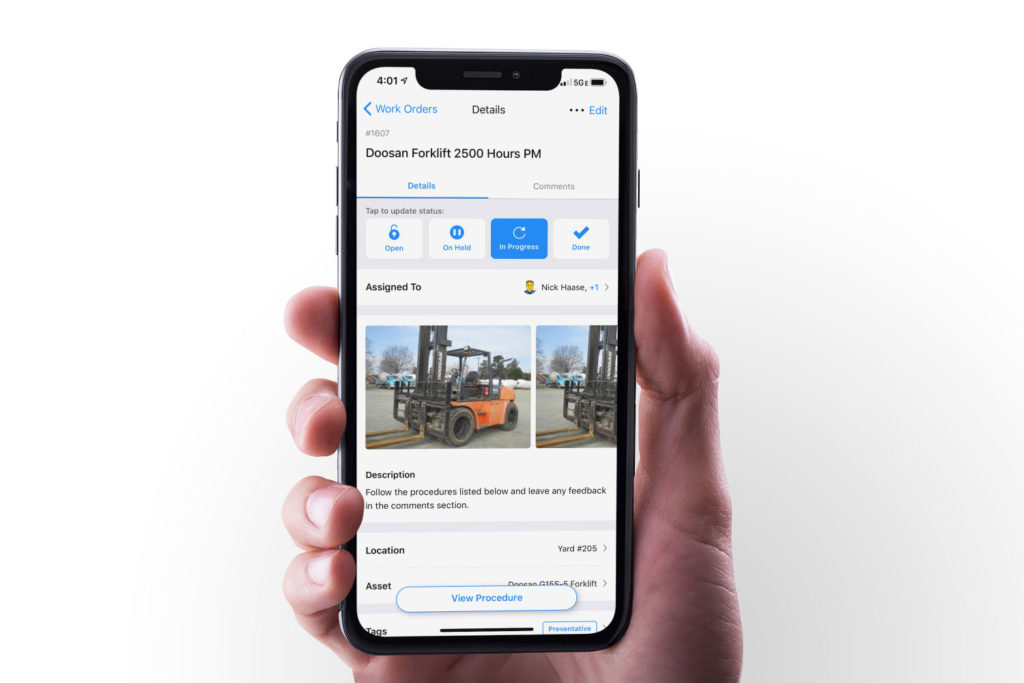

MaintainX

MaintainX is a Canada-based maintenance management software tool with inspection management features. By bringing together maintenance and inspection management together in one place, it makes it easier to identify safety issues and get them resolved.

Manage Your Inspections Faster With OptimoRoute

You can’t go wrong while choosing an inspection management software, but you should consider adding a route optimization tool like OptimoRoute to give your inspection teams more efficiency in the field.

It’s easy to get started with OptimoRoute — just sign up for our 30-day free trial today!

Try OptimoRoute™ for Free

No installation or credit card required