A Guide to Middle Mile Logistics

6 min read

Middle mile logistics is often overlooked and misunderstood, mostly because companies assume they can’t optimize this step like they can with the last and first mile. But companies like Amazon and Walmart are seizing opportunities to save money, time, and other resources by reviewing their middle mile operations and finding ways to improve them.

Business owners need to fully understand and take control of all three stages of shipping logistics: first mile, middle mile, and last mile. Only by fully understanding every stage of the delivery process can you identify where you can improve efficiency along the way.

Here’s what we’ll cover in this guide:

- What Is Middle Mile Logistics?

- Middle Mile Logistics vs. Last Mile Logistics

- Benefits of Optimized Middle Mile Logistics

- How to Optimize Your Supply Chain From Middle Mile to Last Mile

- Middle Mile Logistics FAQs

What Is Middle Mile Logistics?

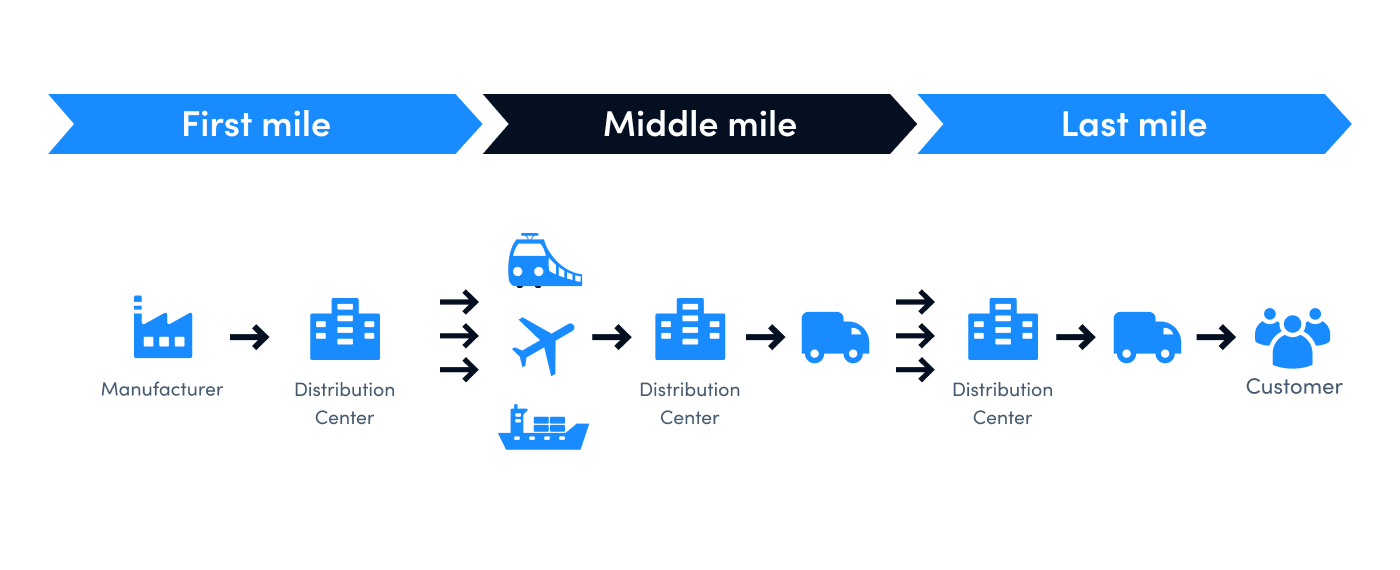

Middle mile delivery is the point in the supply chain where goods are transported from one facility to another, before being picked up for delivery. The route of a middle mile delivery is usually from a holding or fulfillment center to a distribution hub.

Middle mile logistics refers to the operations needed during middle mile delivery. It’s the process of working with truckers to move product from the two locations. Middle mile delivery requires proper planning and scheduling based on trucker availability, order load, inventory, and other factors.

Middle Mile Logistics vs. Last Mile Logistics

In addition to middle mile delivery, there are two other steps in supply chain delivery to optimize: first mile and last mile delivery. The main difference is where the product gets transported to.

First mile logistics

First mile logistics is the operations for delivering product from the manufacturer or retailer’s warehouse to a holding or fulfillment facility. This is the first step in the process of moving the product from production to the customer. Each order needs to be fully accurate from the first mile in terms of labeling, packaging, and shipment to keep the process on schedule. Keeping things accurate in the first mile can ensure on-time deliveries to your customers in the final mile.

Middle mile logistics

Optimizing your middle mile logistics can improve your supply chain. Bottlenecks tend to happen during middle mile delivery while the product goes from a fulfillment facility to a distribution center. For example, let’s say you have one driver picking up 500 orders from a fulfillment center to then deliver to a distribution hub. Now, say the driver gets delayed because of hold-ups at the distribution center. That’s 500 customers who are now likely to receive late deliveries.

But by taking control of the process, you can manage truck driver schedules and look for delays or disruptions at the fulfillment and distribution centers you use. You can coincide with drivers and facilities during first and last mile deliveries, so orders continue moving through the supply chain efficiently.

Last mile logistics

Last mile delivery is the process of getting the product from a distribution center to the customer or a retail store—it’s the last part of the supply chain. Optimizing your last mile logistics means getting your product to the customer as quickly, affordably, and accurately as possible.

Bottlenecks that happen during the middle mile can have a negative effect on last mile deliveries. When you have efficient last mile logistics in place, you can compensate for those obstacles and still get each shipment delivered to the end-user on time and accurately.

Benefits of Optimized Middle Mile Logistics

Optimized middle mile operations give companies better control and organization over the coordination of the supply chain process, from production to delivery.

Improves last mile delivery

One of the biggest challenges with last mile delivery is coordinating large numbers of packages, each to their own unique destination. You need more drivers to deliver smaller numbers of packages. The last mile requires more drivers with lots of stops, complex routes, and more time on the road.

Improving your middle mile logistics can improve last mile delivery and the customer experience. Because of how complex the last mile is, you need your middle mile deliveries to stay on time and move through the process as scheduled. By optimizing the process, you’ll save time and have more leeway to accommodate for problems in the last mile and still deliver on time.

Builds a more efficient & flexible supply chain

When you optimize your middle mile delivery, you have the ability to coordinate trucks and the entire supply chain, which means you’re able to make each step more efficient. You’re able to more quickly identify and fix bottlenecks throughout the route or delivery process. With this level of control and flexibility, you can make changes to routes as needed or communicate directly with the drivers to ensure on-time delivery. For instance, diversifying your fleet of middle mile delivery drivers gives you more flexibility when disruptions happen, like drivers being unavailable or delayed with other deliveries.

How to Optimize Your Supply Chain From Middle Mile to Last Mile

There are different ways to optimize your middle and last mile logistics, like bringing them in-house or using tools to automate different processes. Which of these makes sense for your business depends on where your obstacles happen most often in the supply chain.

Bring middle mile & last mile logistics in-house

To gain full control over middle mile and last mile logistics, bring them in-house so you can manage the processes more directly. The last mile is often the most expensive and the most time consuming. Because last mile delivery accounts for 53% of your total shipping costs, it’s important to make sure everything up to that stage is running smoothly and efficiently. This direct control over your middle mile logistics pays off later, giving you more insight into areas where you can reduce shipping and delivery costs in the last mile.

To bring middle and last mile logistics in-house, you need a dedicated team to handle the planning and coordination. Once you have a team in place, they can start identifying inefficiencies in the middle mile and last mile operations.

Use a warehouse management system (WMS) to optimize warehouse operations

Being able to find and prepare items before they’re even on the truck is crucial to maintaining middle mile efficiency. A warehouse management system (WMS) can help you easily track product in your warehouse by monitoring inventory and order fulfillment levels. With WMS, you can see when new inventory arrives and when it ships out. When you have that level of control over your warehouse operations, you can easily figure out when it’s time to replenish product or when you need to work on reducing inventory and selling the product you have on hand.

Use route optimization software to streamline deliveries

With logistics route optimization software, you can find the fastest delivery routes for your drivers at once and reduce the chances of human error that slows down your crucial final delivery steps. The software uses automation to help you plan the sequence of pick-ups and stops that your drivers need to make during delivery – meeting delivery time windows and minimizing overtime. Route optimization software is essential for coordinating your deliveries quickly and accurately. You’re able to fit more deliveries in each day by finding the most efficient routes for your drivers and making sure the deliveries are distributed among the drivers efficiently.

Route optimization software also lets you give top-notch service to your customers by sending them a message or email with notifications about the delivery progress. These notifications can also include a photo of the delivery location or captured signature upon completed delivery. Proof of delivery and delivery notifications are especially useful when the customer is not present to receive the delivery directly.

Sign up for a free 30-day trial to see how OptimoRoute can help you optimize delivery with our last mile delivery software.

Middle Mile Logistics FAQs

Below, we answer some of the most commonly asked questions about middle mile logistics and its effect on the supply chain.

What is the difference between first mile, middle mile, and last mile?

The difference in each process is in where the product is picked up and dropped off. In the first mile, product is picked up from the manufacturer or retailer’s warehouse and delivered to a holding or fulfillment facility for holding. In the middle mile, the product is picked up from the holding center and delivered to a distribution hub. Finally, in the last mile, the product is delivered to the customer.

How does middle mile logistics affect the supply chain?

Poor planning of the middle mile can slow the supply chain process down. During the middle mile, businesses need to coordinate delivery drivers with the packages that need to be picked up and dropped off from various facilities. A well-coordinated schedule in the middle mile can keep things on track for last mile delivery.

What is the problem with last mile delivery?

It’s expensive, but your customers expect fast and free delivery. That’s where route optimization software can help meet customer expectations while managing transportation costs. The OptimoRoute team can help you plan last mile delivery routes that you can track to make sure your orders are delivered on time, every time.

Try OptimoRoute™ for Free

No installation or credit card required