Accurate Inventory Optimization and How It Can Transform Your Business

For many business owners, inventory and warehousing is nothing but a source of stress. They definitely don’t consider it a business opportunity.

By erring on the side of caution, you not only incur unnecessary holding costs, you also lock up working capital.

Of course, if you run out of stock, you risk losing loyal customers because consumers can easily find another retailer on the internet.

Inventory optimization is all about balancing your priority on satisfied customers with preserving as much capital as possible.

In this article, we’ll explain what inventory optimization is, why it’s important, and different ways you can start an optimization process within your company.

To navigate to the section which interests you the most, click below:

- What Is Inventory Optimization?

- Why Is Inventory Optimization Important?

- How Do You Optimize Inventory for Your Company?

- Speed Up Your Logistics to Make Smaller Inventories Possible

What Is Inventory Optimization?

Inventory optimization is the process of finding the optimal amount of inventory to keep for your business.

The goal is to avoid going out of stock and making your customers wait. At the same time, you want to invest the smallest amount of working capital in inventory.

It may sound like the two ideas are fundamentally at odds, like cats and dogs, but they’re not. It’s not like you’ll mindlessly reduce your stock.

Instead, you should follow a slow-and-steady process to optimize your supply chain. That will give you the space to reduce inventory without risking stockouts.

But what’s the big deal anyway? Why is it essential for further growing your business?

Why Is Inventory Optimization Important?

Inventory optimization is key to establishing a healthy business operation with a good cash flow.

Out-of-stock events can cost you loyal customers

If you just jump in and try to cut your inventory, you’re guaranteed to go out of stock of certain SKUs.

And telling a customer who’s paid for a product that it’s out of stock is bad for business. Usually, it’s a surefire way to lose a sale. The negative experience may even put repeat business from loyal customers at risk.

More inventory means less available cash flow to invest in growing your business

The more capital you have locked up in inventory that won’t sell for months, the less cash you have on hand.

That means you may not be able to rush that R&D project or develop a new marketing campaign.

Sure, you could choose to get a loan for other projects. But business loans have interest rates as high as 8-10% and involve spending extra time and energy on jumping through hoops.

Overstocking is a mistake that can severely impact your company’s ability to grow.

Excess inventory means extra holding costs

Holding or carrying costs are estimated to be between 15-25% depending on the product and industry.

So the difference between having one month’s and three months’ inventory on-hand is massive.

You could end up paying 50% of what the products originally cost in extra ongoing costs by keeping that much inventory.

The key is to find inventory levels that avoid stockouts while still tying up a lot less cash and warehouse space.

Let’s examine the how behind achieving your ideal inventory more in-depth.

How Do You Optimize Inventory?

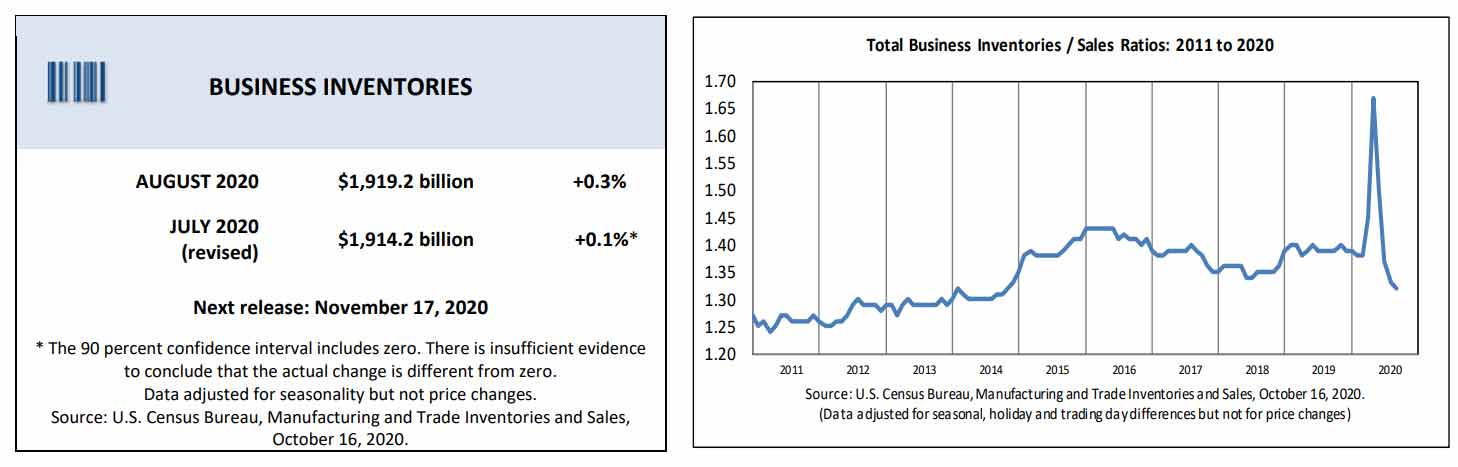

According to the US Census Bureau, US companies held, on average, $1.32 in inventory for every dollar of product sold in August 2020.

That’s a little over one month of sales in excess inventory.

If your inventory is a lot larger than that, you should probably start by safely reducing your stock.

Identify the ideal reorder points for your products

The first step towards lowering your inventory levels is to find the ideal reorder point for each product in your inventory.

Thankfully, it sounds a lot more complicated than it is. All you have to do is multiply your average daily sales with the lead time for the product.

After that, you add a safety buffer to make sure that unusually high sales or long lead times don’t lead to stockouts.

Read our dedicated guide on the inventory reorder point to learn the exact formula for calculating it.

Calculate a safety stock to avoid running out of stock

To set viable reorder points, you also need a buffer or safety stock level for each product.

Safety stock is all about figuring out the standard deviation for sales and lead times. By predicting worst-case scenarios, you can prepare for them in advance.

You don’t need a Mayan calendar to predict a situation that could lead to a stockout. You just need to run the numbers.

Increase your inventory turnover

On the individual product-level, reorder points are the go-to solution to follow. On a macro scale, you want to measure and increase your inventory turnover.

Measuring your turnover rates helps you improve your long-term inventory planning. You can also compare your metrics to leading companies in your industries.

The rates will give you a real sense of what stock levels to keep and how to time replenishment.

Use an ERP to manage and track your inventory and speed up replenishment

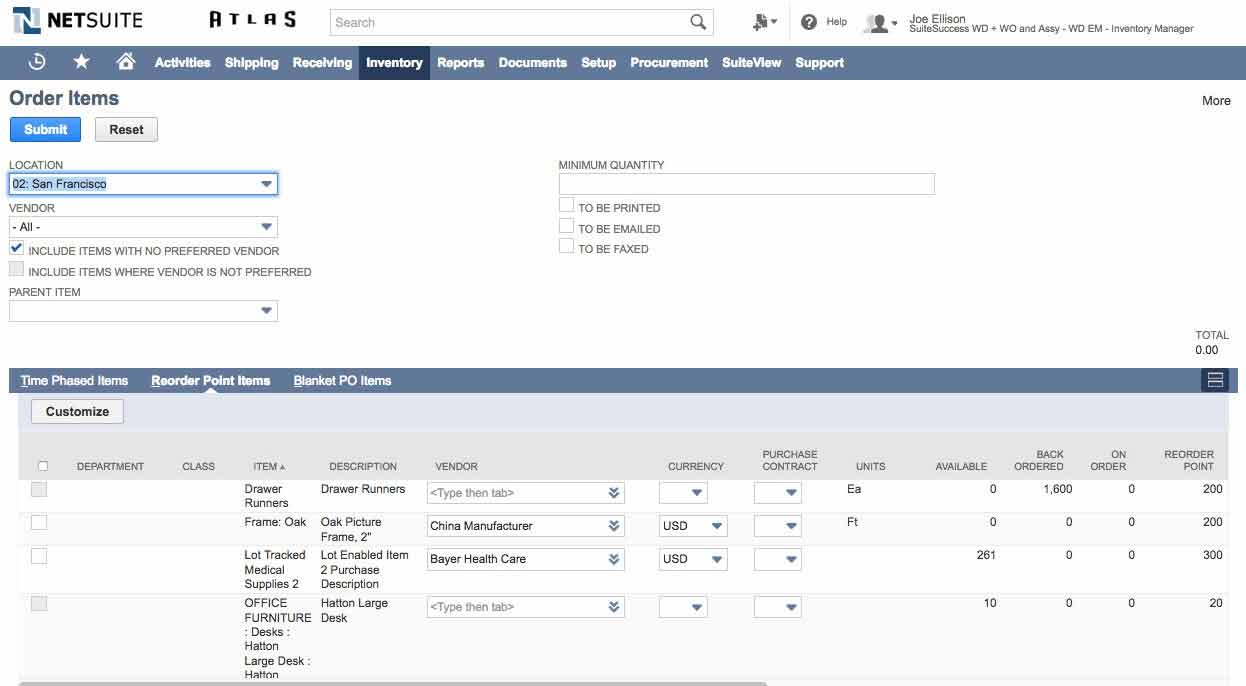

An enterprise resource planning (ERP) solution can help you manage and track your inventory.

It will monitor the number of product units throughout the supply chain and let you know when you should reorder.

That makes it easy to keep the optimal inventory at all times.

You can even register multiple suppliers (including payment methods) and easily place replenishment orders.

An ERP makes following a detailed inventory policy a lot easier for everyone involved.

But even with an ERP, many businesses face issues with phantom inventory or inaccurate records.

After all, it’s humans who are inputting and checking the data.

Improve the accuracy of your inventory data

Data in an ERP is only helpful if it shows the right inventory. If not, the fill rate and other KPIs will be wildly inaccurate.

Run regular cycle counts and compare the real numbers against your records to counteract this. Read our guide on improving inventory accuracy for more information.

Some extra effort for data control is the tradeoff for much better supply chain management.

But even with 100% accurate inventories, there are some problems an ERP can’t solve.

When it comes to the actual shipping or movement of goods, you need a dedicated solution.

To keep up with customer demand and reduce your inventory costs, you must speed up your logistics.

Speed Up Your Logistics to Make Smaller Inventories Possible

The first part of inventory management is reducing inventory and improving processes in warehousing.

But that alone is not enough. You also need to optimize your logistics and speed up the lead times in your supply chain.

If your supply chain has multiple echelons, then this can seem like an impossible task. You have to map out and improve the lead time between each factory, warehouse, and distribution center.

Manually, it’s impossible to do this kind of planning and routing efficiently. But with route optimization software like OptimoRoute, you can find the ideal route in mere minutes.

Easily plan resupply shipments at scale with OptimoRoute

OptimoRoute makes it easy to plan resupply shipments to all your distribution centers and warehouses.

Our software supports long-haul multi-day routes and lets you plan for up to five weeks in advance, in just a few minutes.

It also accounts for real-life variables like driver schedules, delivery time windows, vehicle capacities, capabilities (loading ramp, refrigeration), and more.

Instead of spending hours or days in a spreadsheet, the shipments will be on their way in no time.

Save time with more efficient routes and shipment distribution

When routing manually, it’s almost impossible to distribute orders efficiently. Most companies follow a simple zip-code or service area system.

That rarely leads to optimal delivery times.

Our software can help you reduce mileage by 20% or more across your entire fleet.

Use data-based insights to improve efficiency

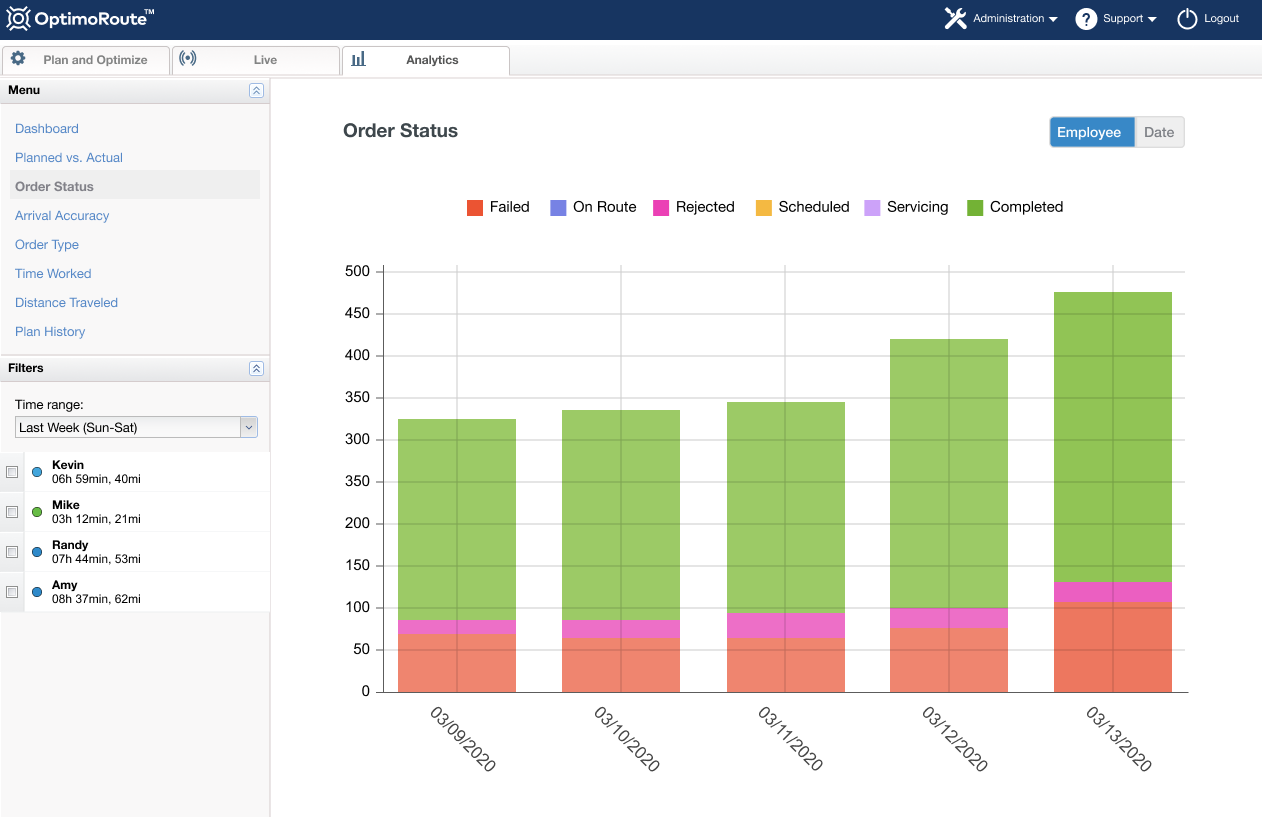

Use our analytics dashboards to check essential KPIs. Identify issues in your logistics chain and fix them.

We provide access to real-time data from the OptimoRoute Mobile App, which uses GPS tracking and delivery prompts to track each driver’s progress.

You can easily discover problems, like underutilized drivers or vehicles, unusually busy weekdays, underserved areas, and more.

You can also use the historical data of deliveries for demand forecasting and planning your inventory. Seasonality is only a problem without data to guide your planning.

Conclusion

Overstocking is a bad business decision, but it’s often born out of necessity.

If you have a slow or unreliable supply chain, you have to compensate with a larger stock.

With OptimoRoute you can tackle this issue, and speed up your lead times and your internal distribution process.

That way, you can reduce your inventory with much less risk of running out of stock.

Start your 30-day free trial of OptimoRoute today and speed up your logistics.

Try OptimoRoute™ for Free

No installation or credit card required