Forward and Backward Scheduling: Definitions, and How You Can Use Them to Compete

Missed deadlines mean lost customers.

This is true whether you’re shipping products, performing installations, or delivering food. Imagine you run a cable company. You have a customer that rearranged their day and stayed home from work to let your installation specialist in during a 4 hour service window. If your worker shows up late, you’re probably going to lose that customer (and likely get a bad review). Fortunately, there are two proven strategies that can help you stay on top of deadlines, increase customer satisfaction, and earn repeat sales: backward scheduling and forward scheduling.

What Is Forward and Backward Scheduling?

Forward scheduling and backward scheduling are planning strategies. Both methods are useful for strategic planning at all levels of complexity. Whether you’re mapping delivery routes for multiple drivers or scheduling maintenance appointments for service teams, you can benefit from using one or both of these strategies.

What is forward scheduling?

Forward scheduling is planning with the primary objective of completing a task as soon as possible, with plenty of lead time. In production and manufacturing, forward scheduling typically means planning to ensure that each step in a process is completed immediately when the time or resources are available.

For a coffee company, forward scheduling would mean planning shipments to go out as soon as the beans are roasted and packaged.

The following forward scheduling examples in personal life and in business illustrate some of the key benefits of this strategy:

1. Let’s say you have a weekend to-do list consisting of yard work and washing your car. If your preference would be to knock-out these tasks first thing Saturday morning, your personality is likely aligned with the forward scheduling method. Crossing things off your list early will allow you to enjoy the remainder of your weekend without stressing about chores.

2. For a business example, let’s say you run a pool maintenance company. You have a client that needs their pool serviced the last week in June. Using forward scheduling, you would schedule this client’s maintenance appointment for the first open appointment slot within that last week of June and get the job done as soon as possible.

What is backward scheduling?

Backward scheduling is planning with the primary objective of completing tasks right on time. Backward scheduling is optimized for flexibility and allows businesses to easily incorporate last-minute changes or customizations.

For a florist, this would mean scheduling bouquets to be arranged as close to the delivery window as possible.

1. Taking the same weekend to-do list example from above, let’s say you live in a climate with unpredictable weather. Washing your car is one of your must-do tasks because you have a client meeting Monday morning, and you want to roll up in a polished vehicle. You could use backward scheduling to tackle your to-do list Sunday evening. That way, there would be less of a chance that your car would get dirty again before your client meeting.

2. Using the business example from forward scheduling, let’s say you have the same client that needs their pool serviced the last week in June. Using backward scheduling, you might decide to schedule this customer’s maintenance appointment for the last day in June, so you have more open time slots at the beginning of the week for new customers.

3. Backward scheduling can also be very beneficial for businesses that offer free returns or exchanges to their customers. Let’s say you run a pet-product company and you have backorders for leashes that need to be shipped on June 10. You receive the inventory of leashes on June 3. Using backward scheduling, you would still schedule shipments for June 10. That way, if a customer decides they want a different color or alternate length leash in the next 7 days, you can still fulfill the order on time and avoid incurring any order exchange or return costs.

Which is better: forward or backward scheduling?

Both backward scheduling and forward scheduling offer advantages. Neither one is better than the other, and each has its own trade-offs; some logistics coordinators even benefit from using a blend of the two. To choose which strategy works best for your business, you’ll need to consider two main factors: what type of business or delivery service you run and how you prefer to organize schedules.

If we refer back to the weekend to-do list example, you could also apply a blend of forward and backward scheduling to accomplish your tasks. You could complete all of your yard work Saturday morning (using forward scheduling) and save just washing the car for Sunday evening (using backward scheduling). That way, you would have peace of mind knowing most of your chores were out of way, along with the assurance that even if it rained Saturday night, your car would still look good for your meeting Monday morning.

Reduce your operational costs by 30%

Increase delivery capacity by 43%

Plan 7x faster

4 Business Challenges Solved by Forward and Backward Scheduling

Using forward and backward planning can help you overcome many of the common challenges modern businesses have with scheduling. These scheduling strategies help you increase process and production efficiency, ensure that you meet delivery dates, balance workloads across employees (and avoid employee burnout), and allow yourself the flexibility to accommodate order changes. Here are a few ways you can overcome business obstacles using backward and forward scheduling.

Meeting due dates

Forward scheduling and back scheduling can help teams meet important deadlines and avoid showing up to appointments late (or early). One of the advantages of forward scheduling is that it can show product pickup and delivery services where they have room to accommodate more orders. Those product pickup and delivery services can then use these open windows to make early deliveries and exceed customer expectations. Backward scheduling helps maintenance and repair companies with standing monthly or quarterly service appointments balance schedules to meet a multitude of deadlines.

Balancing employee workload

A combination of backward and forward scheduling can be used to evenly distribute work across teams of employees and/or drivers. For example, a grocery delivery company could start with delivery windows and work backward to plan routes while making sure each driver was assigned the same number of deliveries. That same company could then use forward scheduling to have their packing team assemble orders as soon as they have time. This ensures that workloads are balanced. Ensuring that your employees aren’t overworked will increase morale, and minimizing underworking employees will reduce wasted spend.

Accommodating changes

Backward scheduling is a valuable tool for certain types of production planning because it allows you to build in time for adjustments to orders. This is particularly advantageous for businesses that create custom products and are familiar with production scheduling. For example, let’s say your business makes custom windows. You guarantee delivery within 30 days, and it takes 15 days to manufacture a window. Using backward scheduling, you could start at the 30-day mark, allot 7 days for shipping or delivery, and then plan your production schedule so that the start date is 8 days after receiving a new order. That would give you the flexibility to accommodate changes for the first week after an order has been placed.

Planning weeks in advance

Both forward and backward scheduling can help you plan further in advance, which will give you a clear projection of revenue and show you process inefficiencies that need to be improved. Combine this with route optimization software, such as OptimoRoute, and you’ll be able to clearly see where you can fit more orders in, when you need to hire more workers to fulfill existing orders, or when you should decrease your workforce based on demand.

How OptimoRoute Makes Scheduling Easier for Businesses

Without backward or forward scheduling, you’re likely to find yourself rushing from job to job, barely making it on time. The following guide can be used to schedule everything from maintenance appointments to food deliveries. Plus, you can get all of these things done faster using route optimization software. OptimoRoute automatically calculates the most efficient schedule up to 5 weeks in advance in just seconds, while factoring in your unique priorities and constraints.

Start weekly planning and get ahead of the curve

Get a jump on order or service requests using the following weekly planning guide. You can use these breakdowns to schedule days, weeks, or even months in advance. We’ve laid out step-by-step planning processes for scheduling using route optimization software or doing it by hand (manual planning). You can use backward and forward scheduling with either of these processes and using OptimoRoute will make it even easier.

Manual planning

- Assemble your existing customer orders or service requests.

- Separate orders by delivery or production process constraints. For example, if you are a maintenance company, you may need to send workers with specific certifications or expertise to some jobs, but not others. You will also need to take into account employees’ work schedules, truck capacities, and lunch breaks.

- Identify deadlines and due dates. Depending on your business, you may want to start with appointment times and use backward scheduling, or you may want to start with orders and plan deliveries based on which orders were received first (forward scheduling).

- Plan routes or service appointments, factoring in constraints and deadlines. You will need to allot significant time for this, especially if your business is complex and has multiple constraints. It is important to note that planning more than a few days in advance can be extremely time consuming and challenging if you are doing it manually.

- Preplanned schedules will then need to be modified each morning before deliveries go out to accommodate order changes or the possibility of your staff calling in sick.

- Reach out to customers to provide service window or delivery updates.

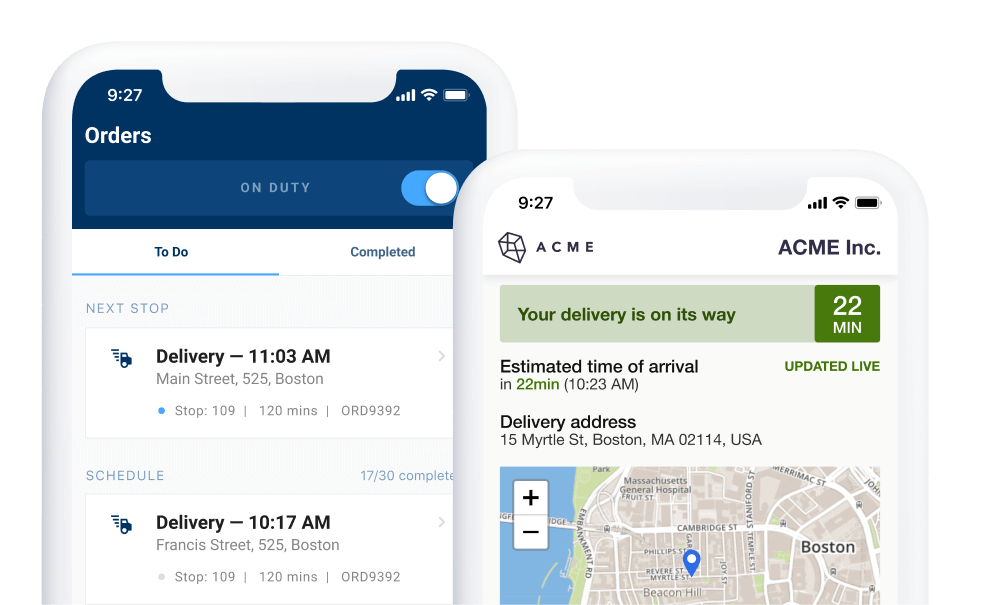

Planning with route optimization software

You can save time, plan further in advance, and adapt to changes more easily by using routing software. OptimoRoute gives you the ability to plan 5 weeks at a time, quickly make changes if an order is cancelled or a driver calls out sick, and much more.

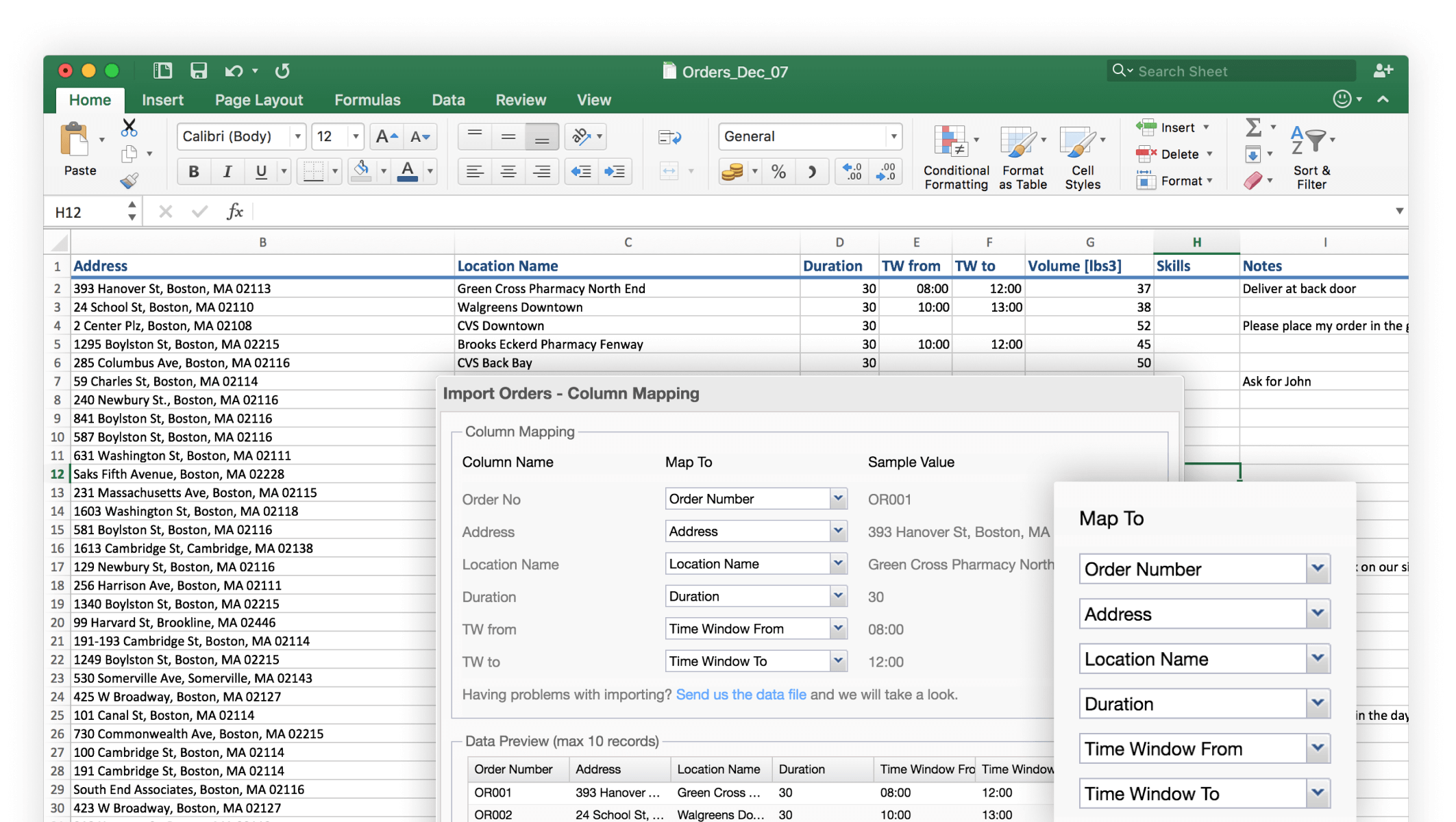

- To begin, upload orders into OptimoRoute from an excel spreadsheet or other source.

- Input all of your service constraints. These can be saved to save you time on future plans.

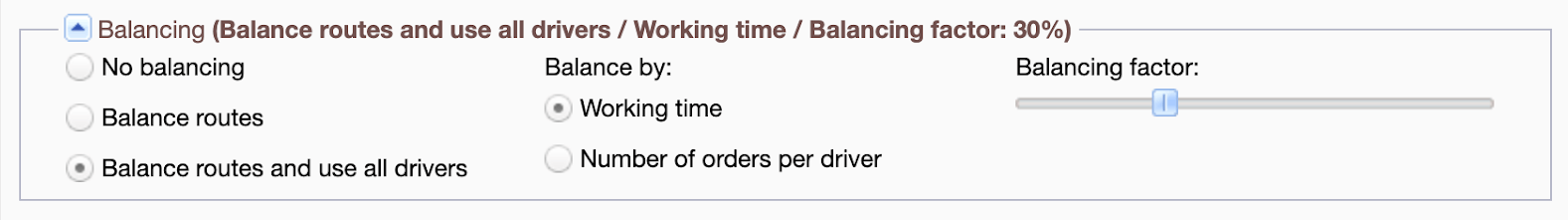

- Decide whether you want OptimoRoute to plan deliveries for efficiency or balance the workload across drivers (or a blend of the two).

- Click “Plan Route.” You’ll get results in just a few seconds whether you’re planning for the next day or the next five weeks!

- Preplanned schedules should be sent to drivers daily so you can make any last-minute adjustments, such as accommodating new orders or having the software quickly replan routes if a driver calls in sick.

- Using OptimoRoute, you can easily text or email your clients a tracking link with real-time order updates so they’ll know exactly when their delivery or their repair professional will arrive.

- Click “Plan Route.” You’ll get results in just a few seconds whether you’re planning for the next day or the next five weeks!

- Preplanned schedules should be sent to drivers daily so you can make any last-minute adjustments, such as accommodating new orders or having the software quickly replan routes if a driver calls in sick.

- Using OptimoRoute, you can easily text or email your clients a tracking link with real-time order updates so they’ll know exactly when their delivery or their repair professional will arrive.

How to optimize delivery/technician routes and logistics with OptimoRoute

Whether your priority is sending drivers on the most efficient driving routes or balancing deliveries across drivers, OptimoRoute can quickly optimize your routes. Advanced features allow you to customize drivers’ shifts, vehicle specs (such as cargo capacity), and maintenance or service requests that require specific skills.

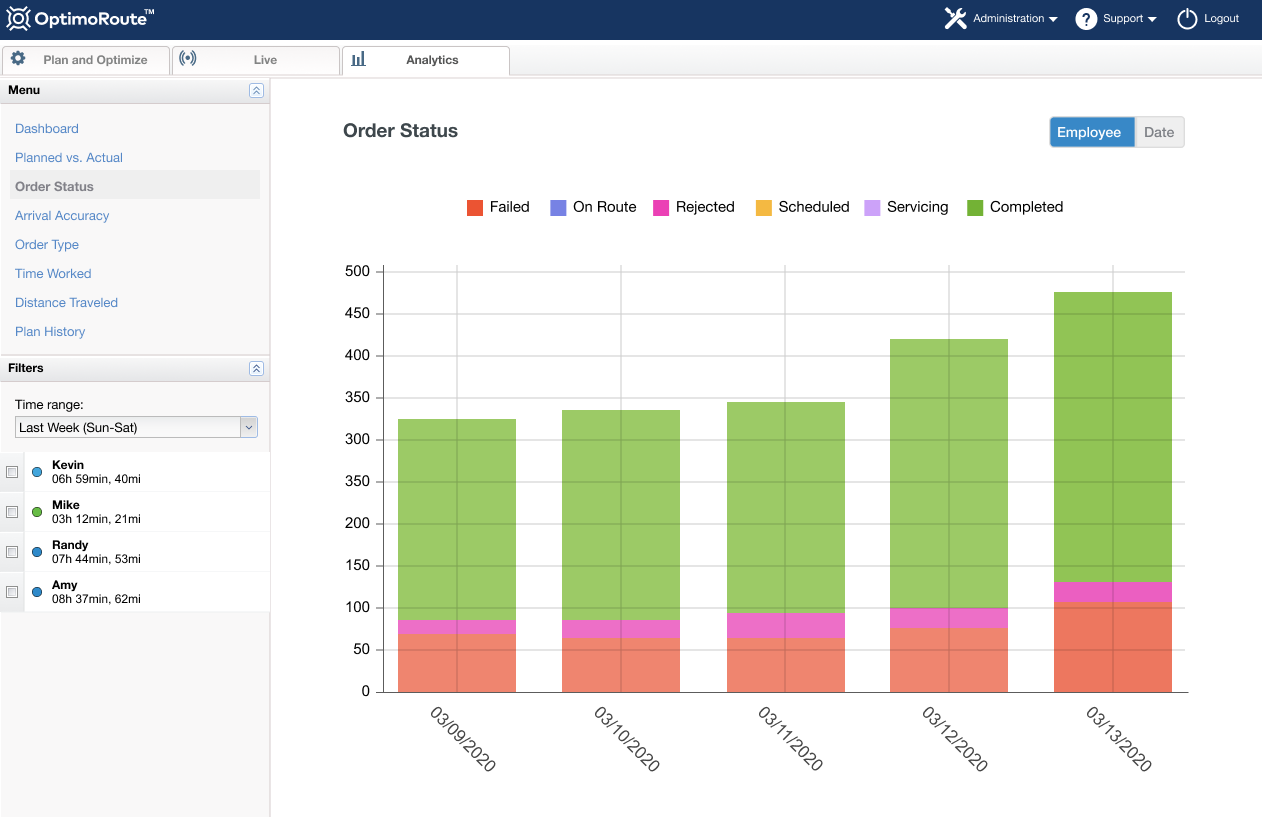

In addition to calculating the best route based on your constraints, OptimoRoute will also help you identify areas where you are excelling or where you can improve. For example, the built-in analytics will show you how each delivery driver or service professional is performing (how often they are on time, whether they typically run late, or whether they could take on a heavier workload). OptimoRoute can also show you when it might be time to hire an additional team member or invest in advanced training for your current employees to fulfill more orders.

Optimize Your Schedule to Adapt With Confidence

Scheduling can be complex and time-intensive, but using backward and/or forward planning strategies will help you get the job done. The most important thing to remember is that a plan is just that—a plan. Even the most thorough plans can quickly go awry when confronted with life’s unpredictability, so forming one that can be adapted if challenges arise is key.

Route optimization software helps you adapt quickly, so you can meet deadlines no matter what challenges arise. With OptimoRoute, you can quickly redistribute deliveries if a driver calls in sick, factor in drivers returning to a depot to reload, and use live tracking to see if a driver changes course due to construction or unforeseen events. Planning days and weeks in advance is easier and more efficient with a solid strategy and the right software.

Try OptimoRoute™ for Free

No installation or credit card required