Operational Efficiency: Lessons From Apple’s History

8 min read

Whether you’re a local pool-maintenance business or a multimillion-dollar corporation, improving your operational efficiency is a low-effort, high-impact strategy to streamline your business. If you’re not keeping an eye on your operational efficiency, you’re missing out on an easy strategy to increase your profit margins and the long-term viability of your business.

Small businesses can see how important operational efficiency can be for them by studying one of the most valuable companies in the world: Apple Inc. In 1997, Apple’s success was far from certain. That year, it posted a $1 billion loss and nearly went bankrupt. But it was able to turn its business around in one year just by focusing on improving its operational efficiency.

Here are the topics we’ll cover in this article:

- What Is Operational Efficiency?

- How Do You Calculate Operational Efficiency for a Business?

- How Do You Improve Operational Efficiency?

- Three Business Areas Apple Made More Efficient

- Maximize Your Operational Efficiency by Following Apple’s Playbook

What Is Operational Efficiency?

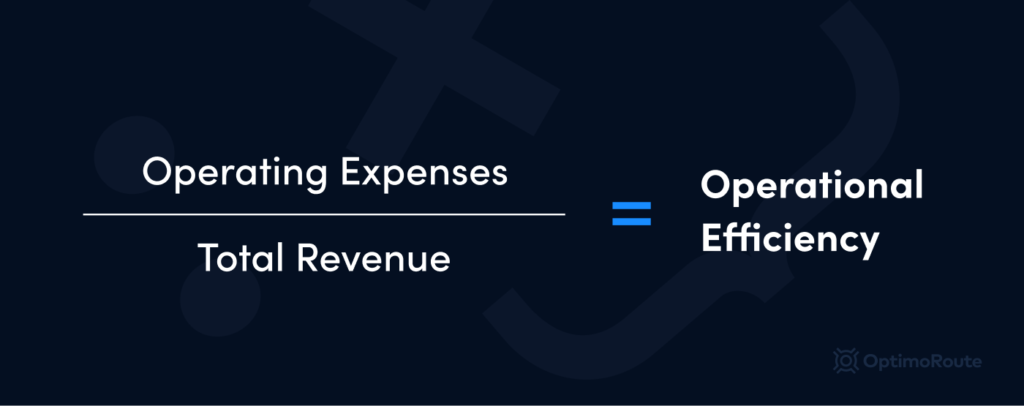

Operational efficiency is the ratio of your business’s inputs (the costs of producing your products and services) to outputs (the revenues generated by selling those products and services). Put simply, if your costs are x and your revenues are y, then your operational efficiency is x/y.

Operational efficiency is an important performance indicator for businesses—the higher your operational efficiency, the lower your costs are to generate the same or more revenue.

Large companies and enterprises tend to focus on improving their operational efficiency regularly through means like automation because they often use more resources than they need to hit their revenue goals. While small businesses tend to operate more efficiently, focusing on improving their operational efficiency can significantly boost their bottom line. Bain and Company recommends that all businesses should incorporate an efficiency mindset into their business model to avoid adding excess resources that only provide limited benefits.

How Do You Calculate Operational Efficiency for a Business?

To calculate your business’s operational efficiency, tally all of your operating expenses and divide the sum total by your total revenue.

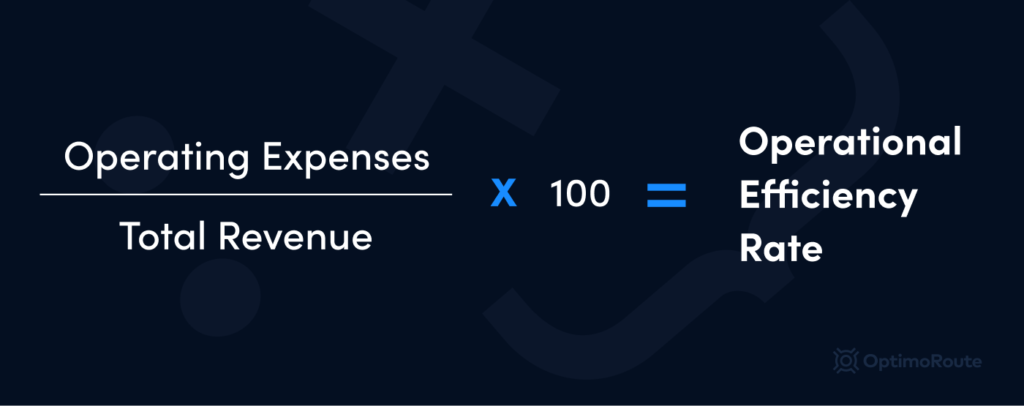

Let’s say your business generated annual revenue of $100,000 and incurred $30,000 in operating expenses. In that case, your operational efficiency ratio is 0.3. You can convert this ratio into a percentage to calculate your operational efficiency rate.

What if, in the following year, your business generated annual revenue of $200,000 and incurred $20,000 in operating expenses? Your operating efficiency rate would be:

As you can see in this example, generating the same or more revenue in a more cost-effective manner reduces your operational efficiency rate. It might seem counterintuitive to understand, but it’s important to remember that the lower your operational efficiency rate, the greater your business’s operational efficiency and sustainability.

How Do You Improve Operational Efficiency?

Improving your operational efficiency involves identifying any expenses you can avoid and replacing them with process improvements for more efficient operations.

Here’s a basic step-by-step framework to help:

1. Audit cost centers

Make a list of all your expenses associated with producing your products.

When Tim Cook joined Apple in 1998, he was tasked by Apple’s co-founder and CEO Steve Jobs to streamline Apple’s operations and improve its operational efficiency. One of the first things he did was audit Apple’s operating expenses.

In this process, one major cost center he learned about was Apple’s inventory management costs. At the time, Apple incurred $400 million just to store and manage parts and unsold Apple machines.

2. Conduct a root cause analysis

Take a look at whether each expense line item is necessary for your business operations. Use the “5 Whys” method to get to the root of each expense. Once you’ve arrived at the root cause of each of your costs, you’ll be able to identify which costs are actually inefficiencies or bottlenecks.

Cook dug into Apple’s inventory management costs by conducting a root cause analysis. He figured out that Apple didn’t have a real-time forecasting system to help it evaluate how many MacBooks it needed to produce every quarter to meet demand. As a result, it often manufactured too many machines and had to hold on to them in its warehouses.

3. Design an alternative business process

Once you’ve identified an inefficiency in your operations, design an alternative process to fix this inefficiency. As part of this step, make sure that you forecast the efficiency gains you expect to have with this new approach. Then, set a target metric or key performance indicator (KPI) against this forecast to benchmark against and help you evaluate whether this strategy is actually working once you’ve implemented it.

To address the inventory problem, Cook decided to invest in a state-of-the-art enterprise resource planning (ERP) system from SAP. The system linked Apple’s resellers and its online store with its manufacturers and parts suppliers so that everyone had real-time data on how many machines actually needed to be manufactured at any given time. Another popular method that businesses often use to improve operational efficiency is an operations management system (OMS).

The metric that Cook sought to improve was inventory turnover time—the number of days Apple held on to its inventory after production before delivering it to a customer. If Apple could reduce its inventory turnover time, it would not need as many warehouses to store its machines, which would reduce its inventory management costs.

3. Test alternative processes

Test your alternative approach by setting some rules around your efficiency experiment:

- Set a fixed time period to test your process. No team wants to execute a defective process for longer than they have to. With a fixed time period, you can motivate your team to rally around a goal and make your efficiency exercise collaborative. McKinsey argues that many strategic initiatives often fail because of a lack of conviction in the organization.

Make sure whatever time period you go with matches your target metric. For example, if your strategy is aimed to improve quarterly revenue, make sure your strategy spans an entire quarter, not just two months. - Assign dedicated team members to help execute the process. These members are sponsors who will shepherd the new process from start to finish. They’ll also keep the team motivated so that they don’t lose sight of why the new process is being implemented by the organization.

- Establish a clear tracking framework to record the progress and any issues associated with executing the strategy.

4. Review the test and decide next steps

After your test period, review the results by consulting with your team and looking at the reports generated during the experiment. Did you achieve the target metrics you set for the experiment? This is a good time to figure that out.

If your experiment was positive and you achieved the efficiency gains you expected, then tweak the process to fix the issues that were identified in the experiment and continue running it in your organization.

If your experiment didn’t achieve your expected efficiency gains, go back to Step 3 and design another strategy based on the new information you got from this test.

In Cook’s first seven months at Apple, he focused on fixing the company’s inventory management issues, and the inventory turnover time dropped from 30 days to six. Apple’s inventory stock worth $400 million also dropped to $78 million. By 1999, Cook was able to reduce Apple’s inventory turnover time even further to just two days’ worth of stock.

Since improving your operational efficiency is a process of continuous improvement, you may want to consider investing in a financial planning and analysis (FP&A) tool to give you real-time insights into which cost centers require efficiency improvements.

3 Business Areas Apple Made More Efficient

In addition to improving the operational efficiency of its inventory management, Apple was able to improve its operational efficiency in its manufacturing, administrative, and delivery operations.

1. Manufacturing costs

If you’re a manufacturing company like Apple, reducing the labor and materials costs associated with your manufacturing processes will result in an increase in your operational efficiency.

In the 1980s and 1990s, Apple owned and operated its own factories to produce its Macintosh computers. Jobs envisioned Apple’s factories as state-of-the-art and highly automated, but they proved expensive for the company to maintain and operate.

Labor

Cook identified Apple’s manufacturing process as another business area that could be made more efficient by several orders of magnitude. Between the late ’90s and early ’00s, Cook outsourced Apple’s manufacturing operations to China, working with Chinese manufacturers like Foxconn to meet its manufacturing requirements.

Outsourcing improved the operating efficiency of Apple’s manufacturing operations because Chinese labor was significantly cheaper than American labor.

Materials

Apple has consistently negotiated favorable deals with its suppliers in an effort to improve the operational efficiency of its supply chain

When Cook joined Apple in 1998, he negotiated with NatSteel, Apple’s outsourced circuit board supplier at the time, to establish their plants close to Apple’s factories to reduce manufacturing time. Apple’s ability to negotiate the best deals with its suppliers continues to this day; recent reports suggest that Apple pays roughly half of what Samsung pays for modem chips in its devices.

With modern procurement tools, you can monitor your spend on materials and vendor relationships to effectively evaluate what you can remove, replace, or negotiate for a lower price.

2. Administrative spend

Regardless of which industry your business operates in, reducing excess or unnecessary team members will increase your operational efficiency.

When Apple was focused on turning around its business in 1997, it reduced its administrative spend with layoffs; Jobs laid off 4,100 Apple employees at the time.

One way Jobs was able to achieve this quickly was by laying off the general managers of all of Apple’s business units and consolidating those units in a single balance sheet. He restructured Apple from operating as a conventional organization, where non-technical managers were responsible for the performance of individual products, to operating as a functional organization, where technical leaders managed technical teams across multiple products.

This restructuring removed an entire layer of management in the organization, which not only increased Apple’s operational efficiency but also made it more effective. Now, team leaders, managers, and other stakeholders had the technical expertise required to make complex decisions that not only affected their teams but the entire organization as well.

3. Delivery management

In October 2020, Apple decided to ship its products to customers from local Apple stores. The decision was made because customers were unable to visit its stores in person due to the COVID-19 pandemic, and Apple wanted to reduce the inventory held by its nationwide network of nearly 300 Apple stores. According to Apple, this would cut costs and potentially improve its profit margins.

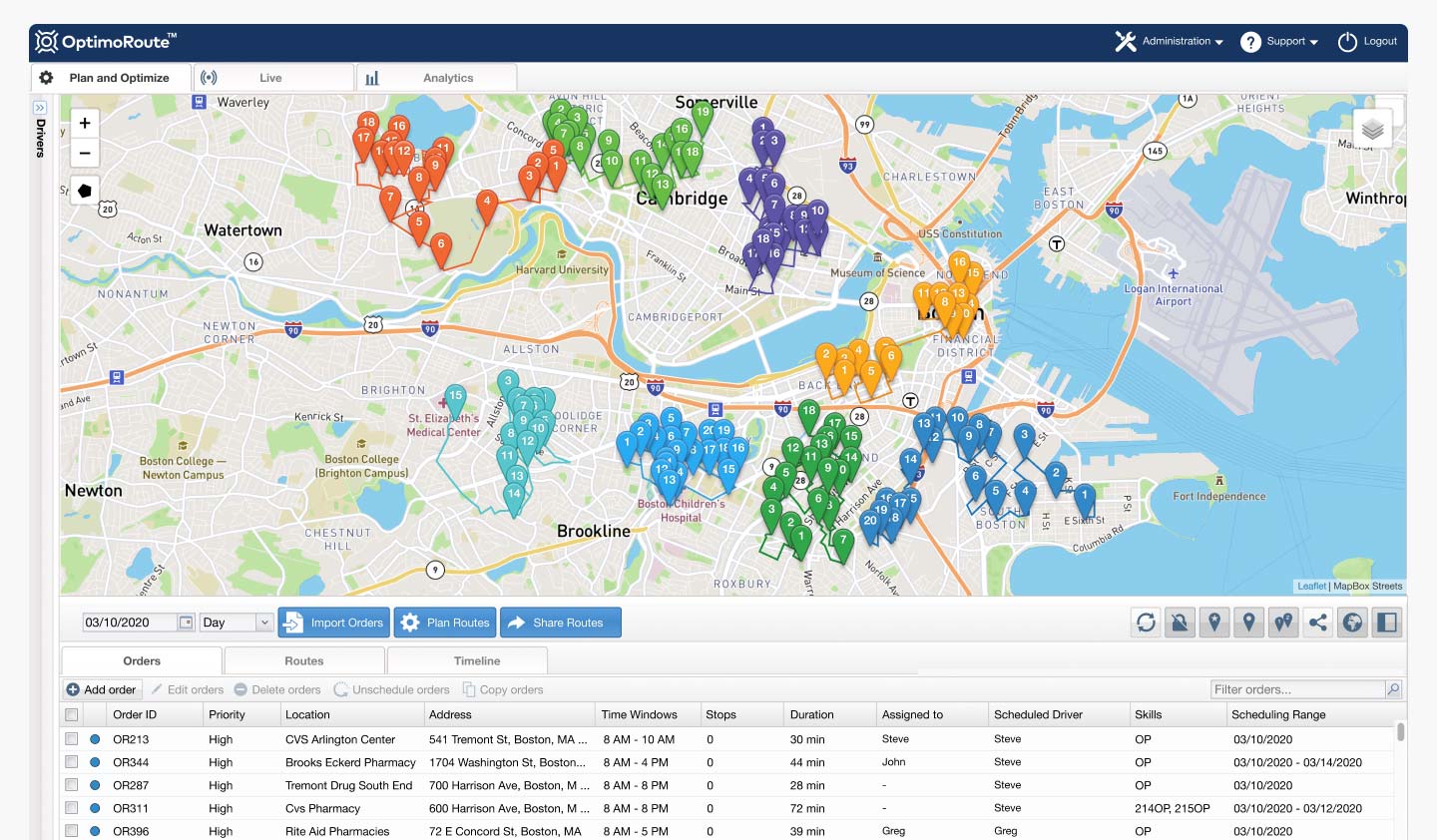

Another method of improving the operational efficiency of your delivery operations is to reduce the number of dispatchers and drivers you need to execute your deliveries. This will increase efficiency in your delivery operations.

Route optimization tools like OptimoRoute can plan hundreds of orders for delivery fleets in seconds, reducing the need to have multiple dispatchers planning routes for your team. They can also free up capacity within your existing fleet so that you can deliver more orders without having to add more resources.

Maximize Your Operational Efficiency by Following Apple’s Playbook

Apple’s turnaround over the last 20 years wasn’t rocket science—it was good business management, and it was assisted by a focus on improving its operational efficiency.

It didn’t take Apple long to see positive results––in 1998, buoyed by Cook’s streamlining efforts and the release of the iMac, Apple turned a profit of $309 million. And this was before Apple released some of its most popular products like the iPod and the iPhone.

Looking to take a page out of Apple’s playbook and improve your operational efficiency? OptimoRoute enables you to improve the efficiency of your delivery operations instantly. Try us out today with a 30-day free trial to get started!

Try OptimoRoute™ for Free

No installation or credit card required