Cold Chain Logistics 101 for Small Businesses

The distribution of COVID-19 vaccines has brought global focus to the concept of cold chain logistics. Over a billion doses of vaccines have been administered globally, but the vaccine distribution process has faced multiple challenges, including unused vaccines and vaccine storage issues. These challenges aren’t unique to the vaccine rollout; they’re common in the world of cold chain logistics.

Cold chain logistics are highly specialized and complex. No matter what size your business is, it’s tough to get right, so it’s important that business owners do the research necessary to develop in-house cold chain processes.

In this article, we’ll break down the cold chain logistics process, common cold chain logistics challenges, and six best practices for managing goods that require cold chain transport.

Click below to navigate to the section that interests you the most:

- What Is Cold Chain Logistics?

- What Does the Cold Chain Logistics Process Involve?

- Common Cold Chain Logistics Challenges

- Six Best Practices for Managing Cold Chain Transport

- Simplify Your Cold Chain Logistics With OptimoRoute

What Is Cold Chain Logistics?

Cold chain logistics involves the transportation and distribution of temperature-sensitive products. It is frequently used in the food, produce, health care, and pharmaceutical industries to transport perishable products that require temperature controls in storage and transit.

For example, meat products like chicken and fish have to be stored at sub-zero temperatures to prevent spoilage from harmful bacteria. Cold chain logistics preserves the integrity of shipments like meats and vegetables that require specific temperatures in their supply chains.

What Does the Cold Chain Logistics Process Involve?

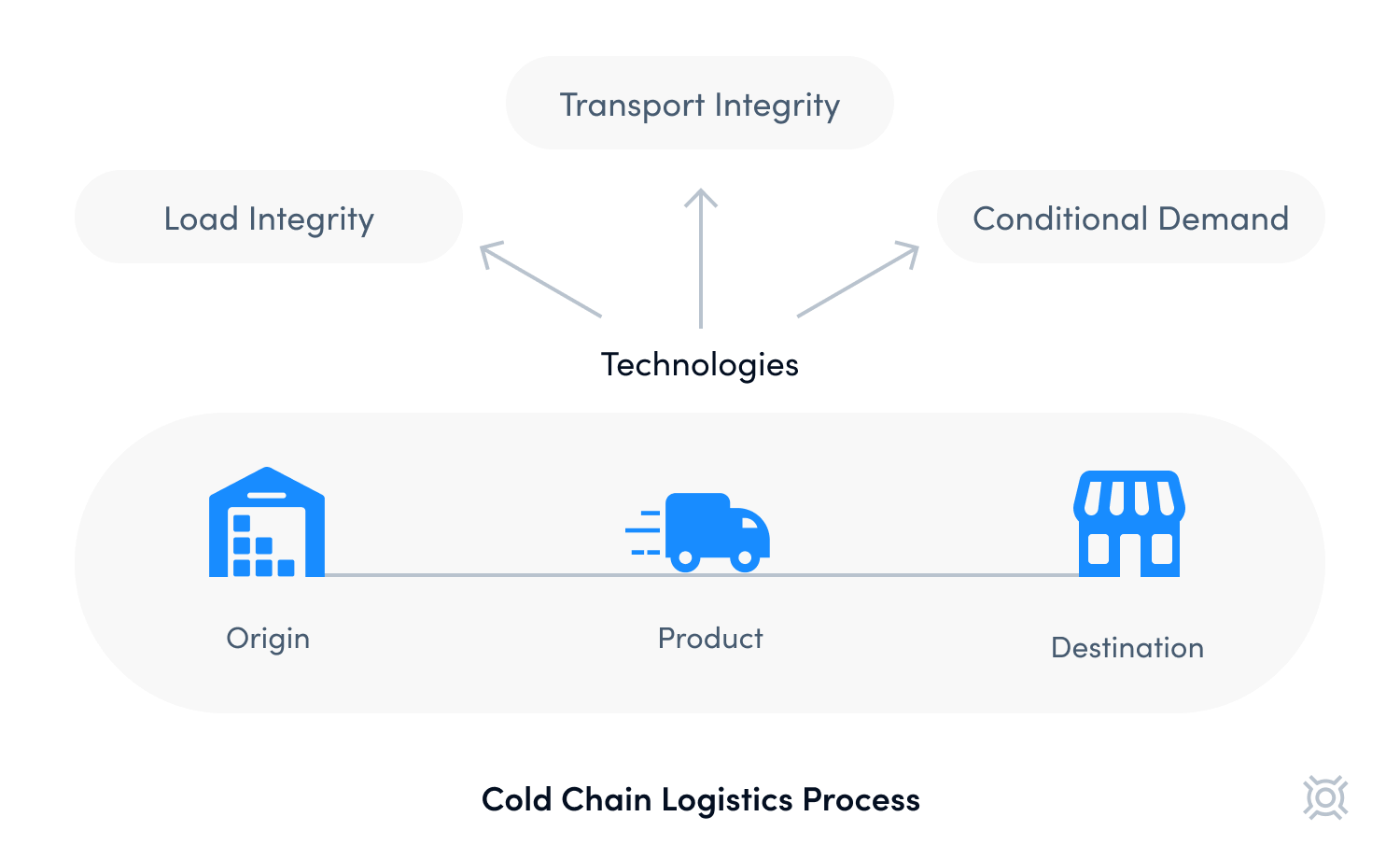

Cold chain logistics is similar to any logistics process where a product is moved through a distribution process from an origin to a destination.

What makes cold chain logistics unique is the conditional demand for products shipped through the cold chain and the technologies required to maintain the load integrity and transport integrity of these products. Let’s break these terms down:

Conditional demand

Arrival time and their state of arrival drive the demand for products that require cold chain shipping.

Fresh produce items like apples need to be refrigerated between -1°C and +4°C. Even at 4°C, they degrade four times faster than if they are stored at 0°C. This means that if a shipment of apples is shipped at even a slightly warmer temperature than required, it can affect their state when they reach a grocery store, impacting whether the grocery store decides to stock them for customers.

Hospitals frequently stock their pharmacy inventory on an as-needed basis. This means that they frequently place orders for medicines when they get orders from their patients. For pharmaceutical wholesalers and distributors, this makes pharmacy orders a priority: Pharmacies give estimated turnaround times to their patients, and if patients can’t get their medicines in time from the pharmacy, they might choose to place their next order with another pharmacy, which reduces future order volumes with a distributor.

Load integrity

Load integrity relates to the technologies required to maintain the products in a shipment. This includes how the product is packed and what refrigeration materials are used in the packaging.

Examples of these technologies include blast freezers, insulated containers, vacuum packing, perforated plastic containers, perforated boxes, etc. Reefer containers are also classified under this category because they maintain load integrity during transport.

Transport integrity

Transport integrity relates to the technologies required to ensure a cold chain’s temperature-controlled environment stays intact.

Examples of these technologies are temperature sensors and monitors in trucks and smart packaging solutions that offer highly accurate data on the temperature life cycle of a shipment.

When you’re building out your own cold chain process, start with your product. Ask yourself these three questions:

- What temperature does my product need to be stored at to maintain its optimal quality?

- What technologies do I need to store my product at its required temperature between its origin and destination?

- Where can I monitor my product’s temperature to ensure it maintains its quality through transit?

Common Cold Chain Logistics Challenges

Cold chain logistics is challenging because of the difficulties of maintaining products at the right temperature during transit.

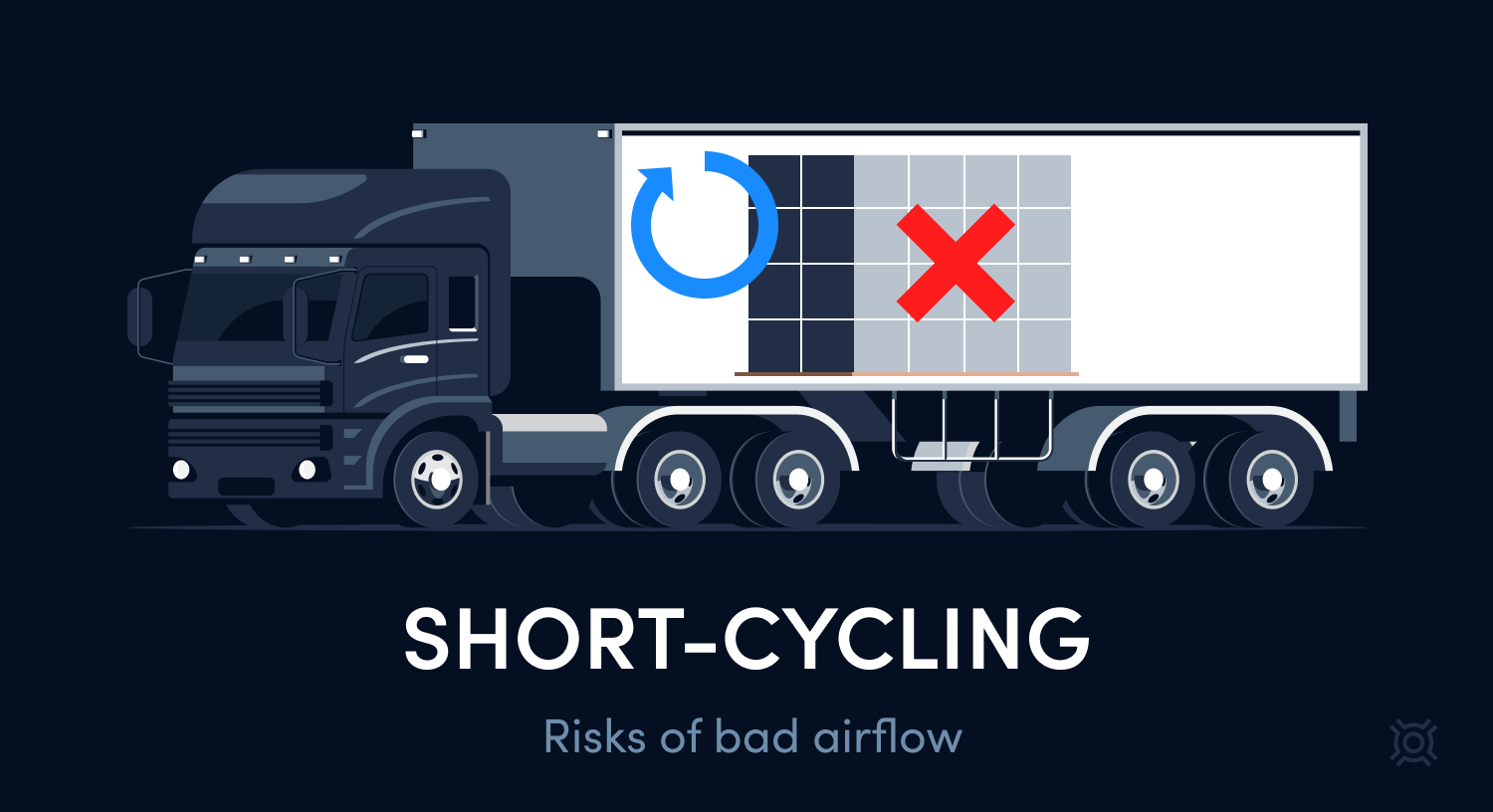

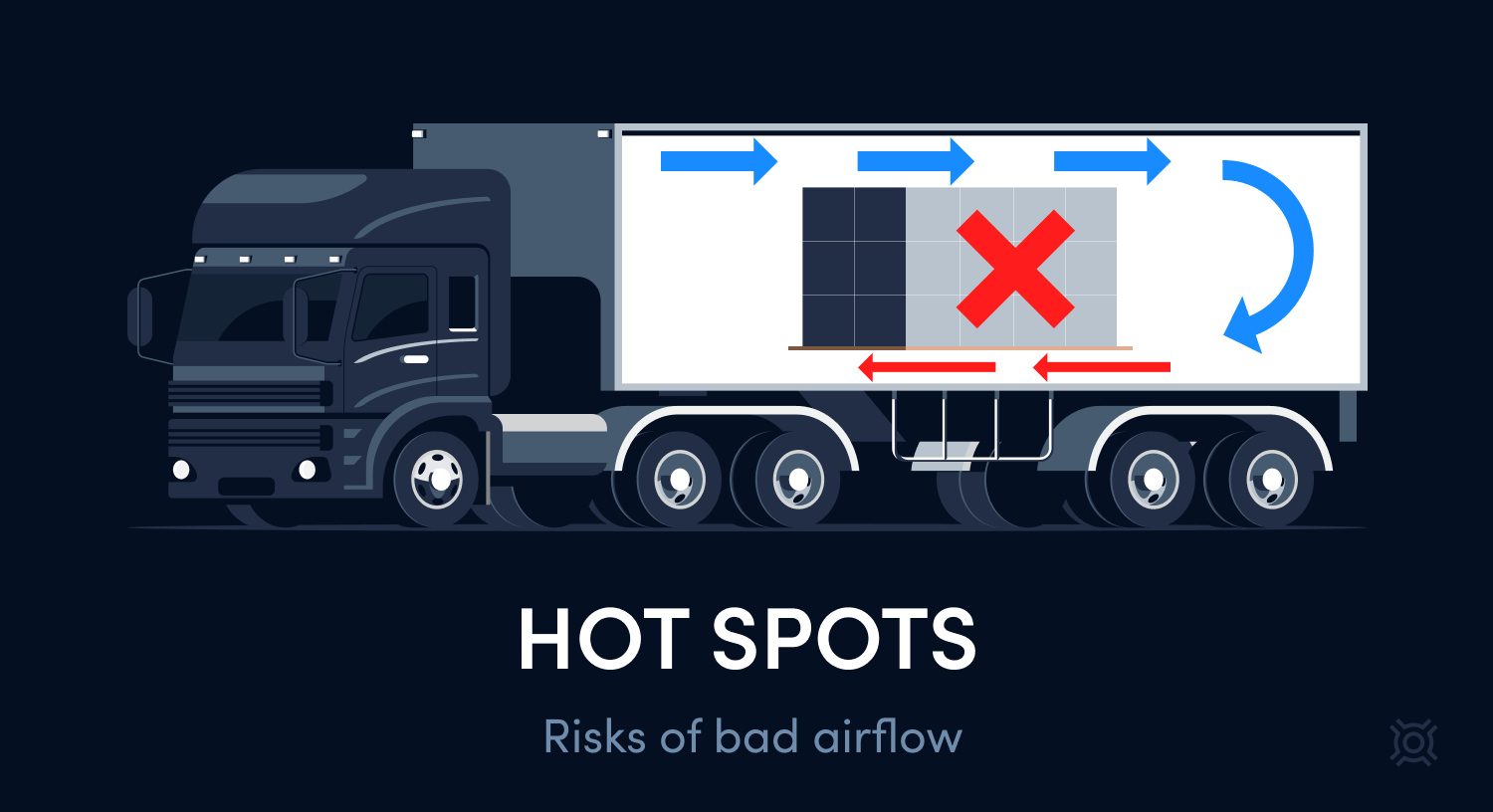

Bad airflow

Airflow refers to the air distribution around products in a refrigerated environment. Good airflow maintains a uniform temperature in your freezers, trucks, and trailers, which preserves your product’s quality. Bad airflow, on the other hand, can cause issues like short-cycling, top-freezing, and hot spots.

Short-cycling occurs when refrigerated air is unable to travel through the full length of the storage or transportation unit. For example, if your pallets are stacked from your truck’s floor to its ceiling, your refrigerated air won’t have a path to go from the cooling unit to the back of the truck, and your storage temperature will be uneven.

Top-freezing occurs when your shipment is placed too close to refrigerated air in a storage or transportation unit. It can cause frost damage to your products.

Hot spots occur when a shipment is not cooled throughout at a uniform temperature, and certain parts of the shipment are at a different temperature than others.

Temperature excursions

A temperature excursion occurs when a product is exposed to the temperature outside its recommended storage temperature range.

Temperature excursions can occur throughout a cold chain process, from its origin to its destination. They can happen for several reasons, including technical failures of cold storage and cold transport units, power failures in a cold storage facility, inspection of products when they cross borders, etc.

For pharmaceutical products, temperature excursions result in product wastage. For example, in 2017, Baxter International recalled shipments of its INTRALIPID 20% IV Fat Emulsion because the product had been accidentally exposed to subfreezing temperatures during transit.

Six Best Practices for Managing Cold Chain Transport

Managing your cold chain comes down to maintaining the temperature of your products. These best practices will help you get there.

1. Prioritize your delivery order

When you’re transporting time- and temperature-sensitive products, it’s important to prioritize the order of your delivery to make sure you satisfy all your customers.

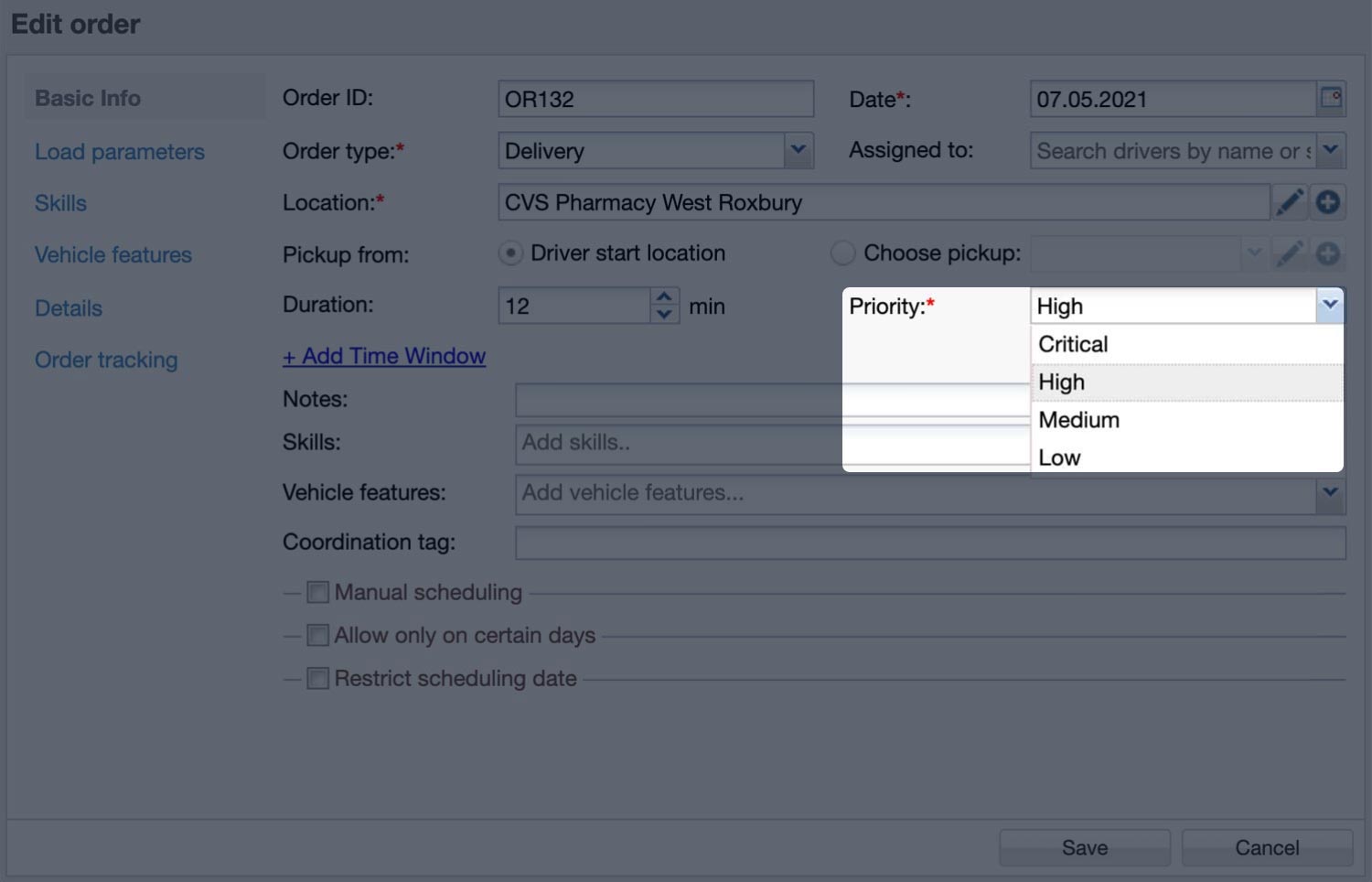

Setting your delivery priority with OptimoRoute is easy. When you upload your orders into OptimoRoute, you can add a ‘Priority’ column to your order sheet. In this column, you can indicate whether an order is L (Low), M (Medium), H(High), or C (Critical). Orders with a higher priority in your order sheet are scheduled earlier.

Once your orders are uploaded, you can plan your routes in seconds by clicking the Plan Routes button in your OptimoRoute dashboard. Our planner takes into account your order priority and plans your routes accordingly.

2. Source the right vehicle and equipment

Your packaging system is critical to maintaining its temperature in storage and transit.

You can choose between active or passive packaging systems. Active systems actively regulate your product’s temperature. These systems include refrigeration units like blast freezers and reefer trucks. Passive systems, on the other hand, maintain your product’s temperature without any active regulation. This includes dry ice, gel packs, and plastic coolers.

Most cold chain systems are a hybrid of active and passive systems. The mix of systems you end up going with will come down to how big your cold chain process is—what your products are, where you plan to ship them, and what your customers expect from you.

3. Perform pre-trip inspections

No matter what mode of transport you use to transport your products in your cold chain process, make sure your drivers go through a pre-trip inspection of your products and vehicles.

Thermo King Europe has a handy checklist to conduct a pre-trip inspection:

- Make sure the refrigeration unit is running smoothly.

- Make sure you have enough diesel for the trip.

- Check your load temperature before loading.

- Make sure the truck is precooled to remove residual heat.

- Perform a defrost half an hour after loading to clear the evaporator coil and ensure maximum cooling performance.

- Inspect the truck for refrigerated air leakage.

- Check the body for condensation when loaded to spot any possible body damage and thermal breaks in the insulation.

- Check that the doors are securely sealed.

4. Ensure optimal airflow for your products

As we’ve already pointed out, bad airflow can harm your products during transit. Here are a few ways you can reduce the risks of bad airflow affecting your products:

- Minimize the number of times you open your refrigeration unit doors.

- Ensure that your loads are well packaged so that they can accommodate optimal airflow.

- Stack loads on pallets—improper loading and wrapping may cause restricted air passages through the load.

- Keep your transport unit floor free of obstructions and debris to prevent air circulation issues.

5. Conduct routine maintenance for your cold chain feet

Ensure refrigeration units are inspected regularly to prevent breakdowns on the field.

Depending on your product value, you could be carrying anywhere from $5,000 to $50,000 of inventory in a single trip. It’s better to maintain your vehicles regularly than to suffer a breakdown that can significantly impact your business.

6. Provide real-time information to your customers

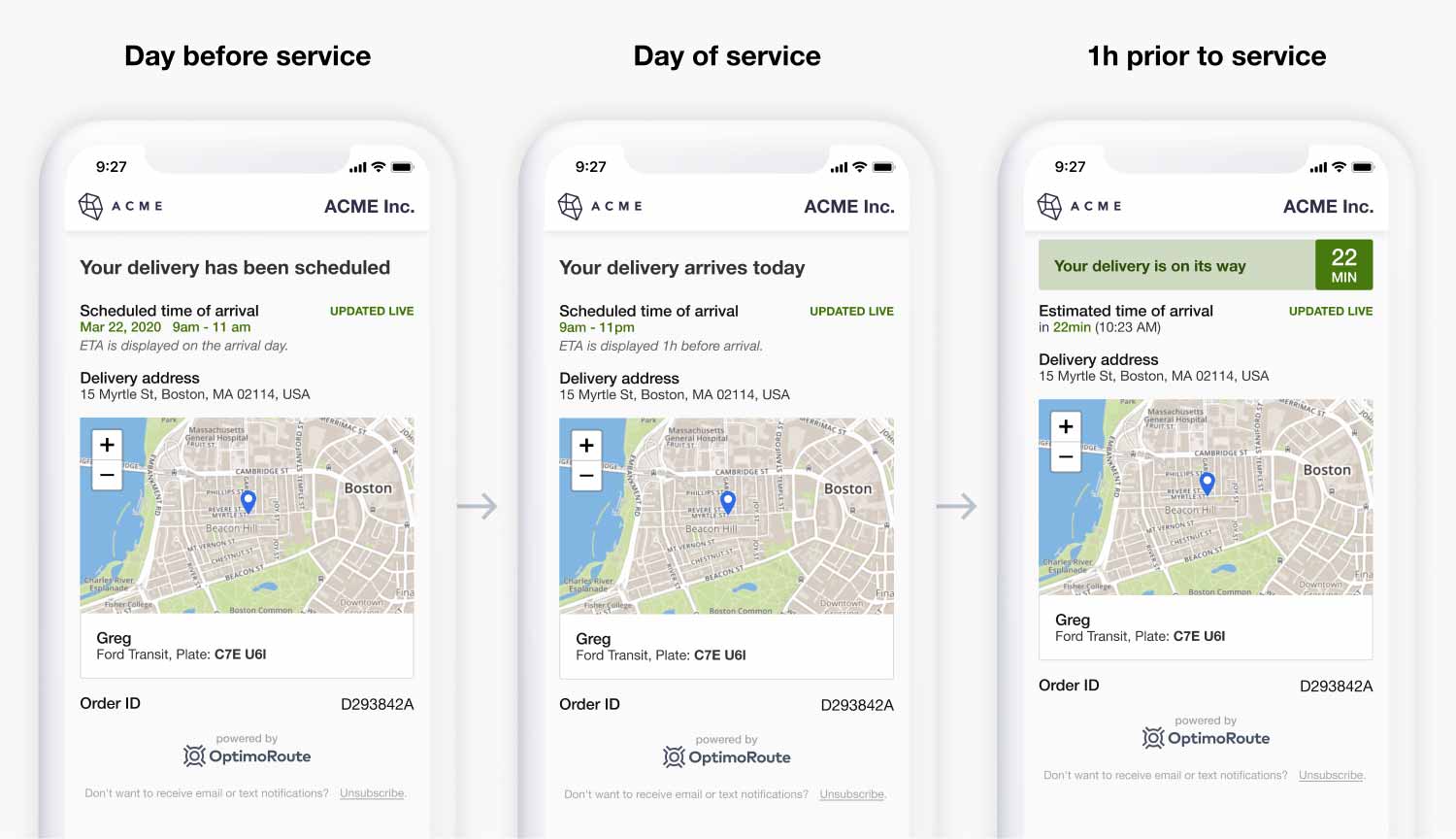

By providing real-time tracking information to your customers, you can put them at ease regarding the status of their shipments, especially for time-sensitive orders.

OptimoRoute lets you share Realtime Order Tracking with your customers via text and email. You can customize your tracking branding and messaging so that your customers know who their tracking information is coming from.

With OptimoRoute’s Web API, you can link OptimoRoute with your temperature monitoring software and share product temperature information with your customer as well!

Simplify Your Cold Chain Logistics With OptimoRoute

Cold chain logistics can be difficult and complex, but they don’t have to be. OptimoRoute simplifies your cold chain logistics workflow so that you can dispatch your temperature-sensitive shipments with ease.

Try out OptimoRoute today with a 30-day free trial!

Try OptimoRoute™ for Free

No installation or credit card required