Field Service Made Easy With Drag and Drop Route Planning

7 min read

Welcome to the first of OptimoRoute’s stories chronicling the experiences and lessons from lives of route planners, as told by those who have dedicated their careers to finding the optimal paths for their businesses.

Bart Bartolozzi, a seasoned veteran in the field of product marketing for high growth SaaS platforms, has spent the last fifteen years helping customers solve their primary business challenges with the right technology. With a decade of experience focused on the service management and delivery logistics markets, Bart has seen firsthand the power of route optimization to deliver speed, intelligence and adaptability to businesses.

Join us as we explore the world of route optimization and discover why OptimoRoute is the best choice for anyone in need of efficient, reliable and adaptable routing solutions.

A while back, I was invited to spend the day out in the field with an HVAC field service company based in South Florida.

Some have named Florida the “air-conditioning capital” of the United States. Florida has the highest ratio of air conditioning to households in the US, at nearly 98% of all homes having some form of air conditioning. Unsurprisingly, Florida has the highest number of HVAC repair people in a state at close to 34,000 field-service technicians. This is one field service technician for every 640 residents. For perspective, the next two closest states are Texas (at one tech for every 922 residents) and California (at one tech for every 1,189 residents).

Like any good guest, I picked up a couple of boxes of joe and assorted bagels and donuts for the HVAC team. I planned to be the first one into the offices at 6:00 am to share with the crew.

I glanced at the left side of the parking lot where the company had its fleet of over 40+ fully equipped AC repair vehicles all lined up and ready for the day’s battle ahead, an impressive display of shiny glass and steel. The right side of the lot was completely empty, except for a single blue Toyota SUV.

Seb, the service & logistics director, quickly buzzed me into the building. He led me up to a small conference room where I could set up breakfast for the team.

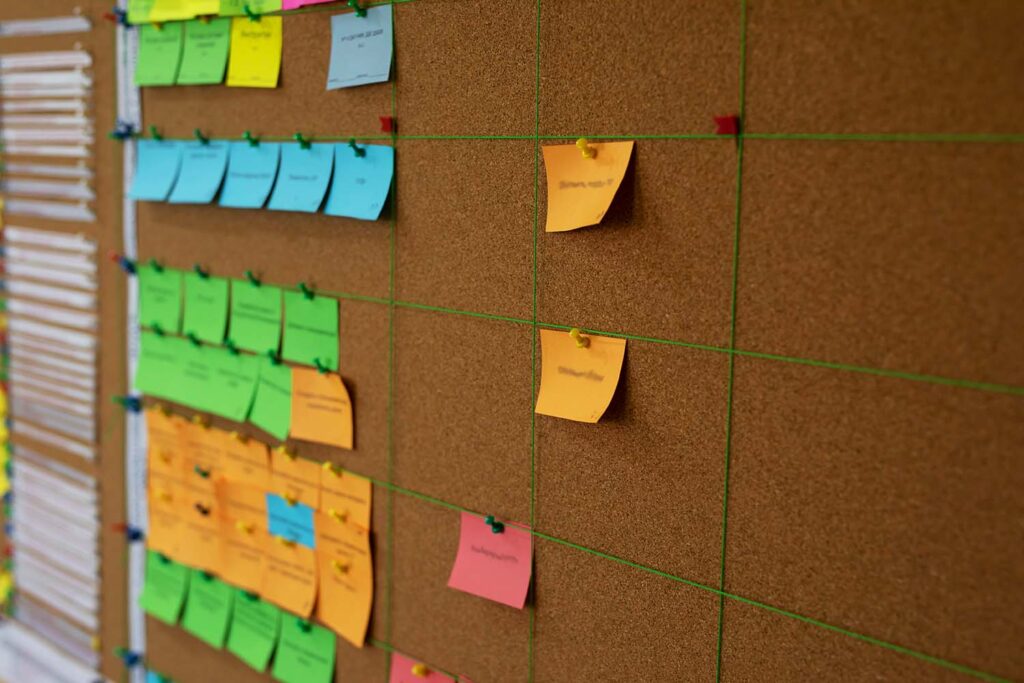

In the conference room, Seb had converted two of the four walls into his primary work area for the day. On 4×6 multi-colored cards were written the names of every member of the field services team that were scheduled to work that day. These cards had been taped from top to bottom on the two walls, almost in a straight line and almost in alphabetical order.

On 3×5 cards Seb had written order numbers, estimated repair times, and technician level requirements. These cards were placed right to left next to each driver’s name. I could also see that there was a small stack of 3×5 cards sitting orphaned on the table as these had still not been placed yet.

Seb said that he normally comes in around 4:30 am to continue the work on the schedule from the night before. He said it normally took a few hours the night before to get the board into its “first pass”, and that now all he needs to worry about is “the good, the bad, and the ugly.”

The “good”, as he explained it to me, was any overnight job cancellation. I am sure that most companies wouldn’t consider a potential lost revenue opportunity as good, but for Seb it was an opportunity to move some of the orphaned cards to the board.

The “bad” was any of the orphaned jobs that he could not find a home for. For these, Seb had to either find another available technician (and hopefully one that would need then push into overtime for the week) or, as a last resort, have his phone agents reschedule with the customer.

Both of these were huge challenges as the business did not want to pay overtime and clients, especially in really warm months, won’t be clients for very long when their service call is canceled or changed.

“What is the ‘ugly’?” I asked Seb.

Seb winced and pointed up to the two walls. “The ugly is when even one of our field techs calls in sick.”

This particular morning was looking especially ugly as he would have to find a home for or “orphan” an additional 16 jobs that day.

Seb attacked the two walls with both desperation and determination. He knew the team members that could extend their days and wouldn’t complain and those who would. He also had a pretty good sense of which ones where additional jobs might push close to overtime and those that wouldn’t. He began to move cards around with the dexterity of a black-jack dealer in Las Vegas.

As it approached 7:15am, he managed to fit in most of the 16 jobs across the available technicians. Seb then had to redistribute the work order piles on the other large table in the corner, so that they now matched the new “schedule” that was pasted across the two walls.

Many of the techs had already arrived at the office to partake in the free breakfast, but most were there waiting anxiously to pick up their stack of work orders for the day.

Seb was also anxious to get the drivers out the door and on their routes, but had one last check to make for any last minute cancellations. Margie, who ran the phones, soon came in with a list of last minute cancellations and Seb quickly pulled eight cards from the board.

This, again, was “the good” as Seb was able to move a few more orders around and reduced those in overtime from eight to six.

“Orders are ready”, Seb shouted with a hard clap of his hands after re-sorting the piles.

The team started to filter in, grabbed their stack of orders and another cup of coffee, and were out the door. Seb slumped back into his seat and let out a big sigh of relief as most of the heavy lifting for the day was done. He had just spent the better part of the last 12 hours dragging and dropping cards from one tech to the other until he felt that he had determined the best fit for the business and the team.

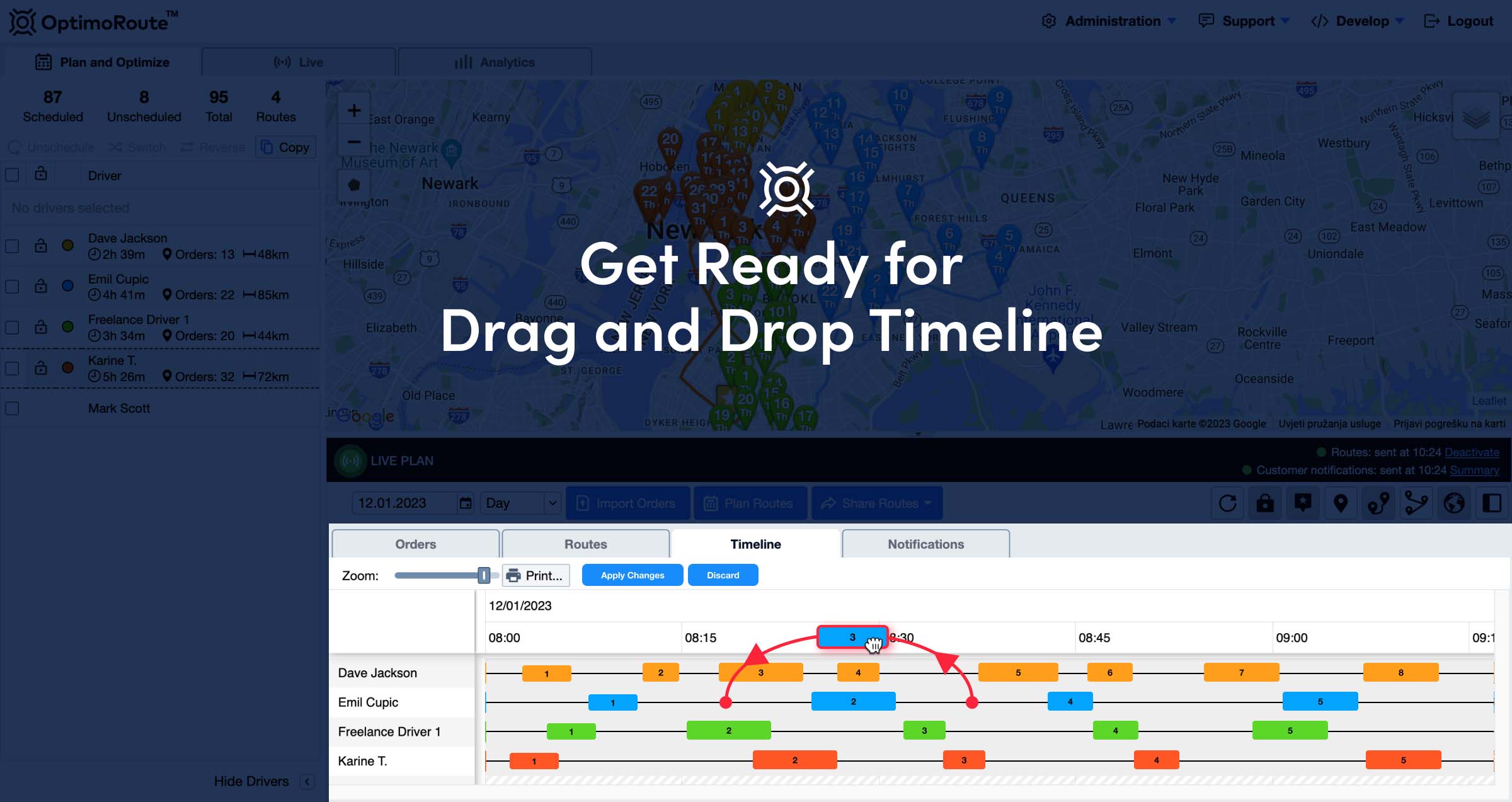

As I was there to talk to Seb more about route planning and optimization, the first thing I mentioned was the “Drag and Drop Timeline” functionality that was in early availability within the OptimoRoute platform.

It would essentially allow him to work the same way he currently did, but with all the advantage of speed and intelligence that the OptimoRoute platform could provide. His daily orders could be ingested into the platform and then planned and scheduled across all of his techs in seconds.

As the most adaptable route planning and optimization solution, OptimoRoute would create the schedule with full understanding of service technician skill requirements needed, customer priority and even if certain jobs required coordination between more than one technician for a large installation or project. With a single click, these orders could be pushed to the field techs via the OptimoRoute Mobile App. Techs could start their day without having to wait around, and Seb would save close to 12 hours in planning and scheduling.

The Drag and Drop Timeline would also give Seb the ability to make changes on the fly to handle last-minute cancellations from customers or any issues being reported back in the field. Instead of doing this on the two walls of the conference room, as he normally did.

In OptimoRoute, Seb would be able to make these moves and changes with a few clicks on his laptop. Instead of texting or calling the techs in the field, he could send these changes to all of the impacted field teams with a single click. Seb liked the idea of managing these drags and drops from his laptop as it was very similar to the way that he had always done things, with the big difference being that he could do these changes in a matter of seconds, rather than hours. It was familiar and comfortable to him as it matched his current workflow.

I also let Seb know that there was an even easier workflow that he could implement within OptimoRoute, in that as orders were canceled or techs called out sick, he could simply allow the adaptability, speed and intelligence of the OptimoRoute platform do all the work for him by replanning his routes.

As Seb sat back further in his chair, he smiled as he quickly realized what all of this would mean to the company and for him personally. It meant that they would potentially never have to “orphan” an order again. It also meant that they could easily accommodate changes, technicians calling in sick, and cancellations at any time across their day.

It also would eliminate those “mistakes” that would always arise when Seb had to make some last minute drag-and drop-decisions because – sometimes in the heat of the moment – customer priority, skill-set requirements would be forgotten or overlooked as he was fighting to get all orders planned.

For Seb, it would allow him to manage the team more effectively – ensuring that the team was equally splitting the work and reducing their overtime. Seb also realized that he probably could keep more regular hours given that he does not receive overtime. It also meant that he could spend more time on customer follow-up to help build out more upsell opportunities, ensure customer satisfaction, and evaluate field-tech performance.

For Seb and his company, OptimoRoute would provide them with the tools and a competitive advantage in a market known to be the “air-conditioning capital of the US”.

For other OptimoRoute clients, if you would like to be an early adopter of new features like the Drag and Drop Timeline, please let us know by sending a note to sales@optimoroute.com and you can start leveraging this capability in your business today.

Try OptimoRoute™ for Free

No installation or credit card required