What is Inventory Turnover? + 6 Ways to Improve Your Inventory Turnover Ratio

February 19, 2021 10 min read

Inventory turnover ratio is the business metric that tells you how healthy your product business is. It factors in not just how much inventory your company sells but also your supply chain efficiency, cash flow, profitability, and the effectiveness of your inventory control and management efforts. Calculating your inventory turnover ratio is akin to a doctor taking a patient’s temperature. An unhealthy ratio, just like a high temperature, is a surefire sign of a problem.

But identifying the existence of a problem is only half the battle. To put this vital metric to good use, you don’t just need to know how to calculate inventory turnover rate—you need to know how to improve it.

Read on to learn:

What Is Inventory Turnover?

What Is a Good Inventory Turnover Ratio?

Use Our Inventory Turnover Calculator

6 Ways to Improve Your Inventory Turnover Ratio

Increase Inventory Turnover by Streamlining Last Mile Delivery

What Is Inventory Turnover?

Inventory turnover is the rate at which a company’s inventory is sold and then replenished. An inventory turnover ratio of 2, for instance, indicates that you sold and replenished twice the amount of inventory you stored.

Product businesses measure inventory turnover using the inventory turnover ratio to gauge the efficiency of their supply chain and warehousing processes and the level of demand for their products.

Inventory turnover ratio is often used in tandem with metrics like day sales of inventory (DSI) which measures the average time it takes for inventory to be converted into a sale. To properly determine your inventory turnover, you also need to make sure that your inventory counts are accurate.

What Is a Good Inventory Turnover Ratio?

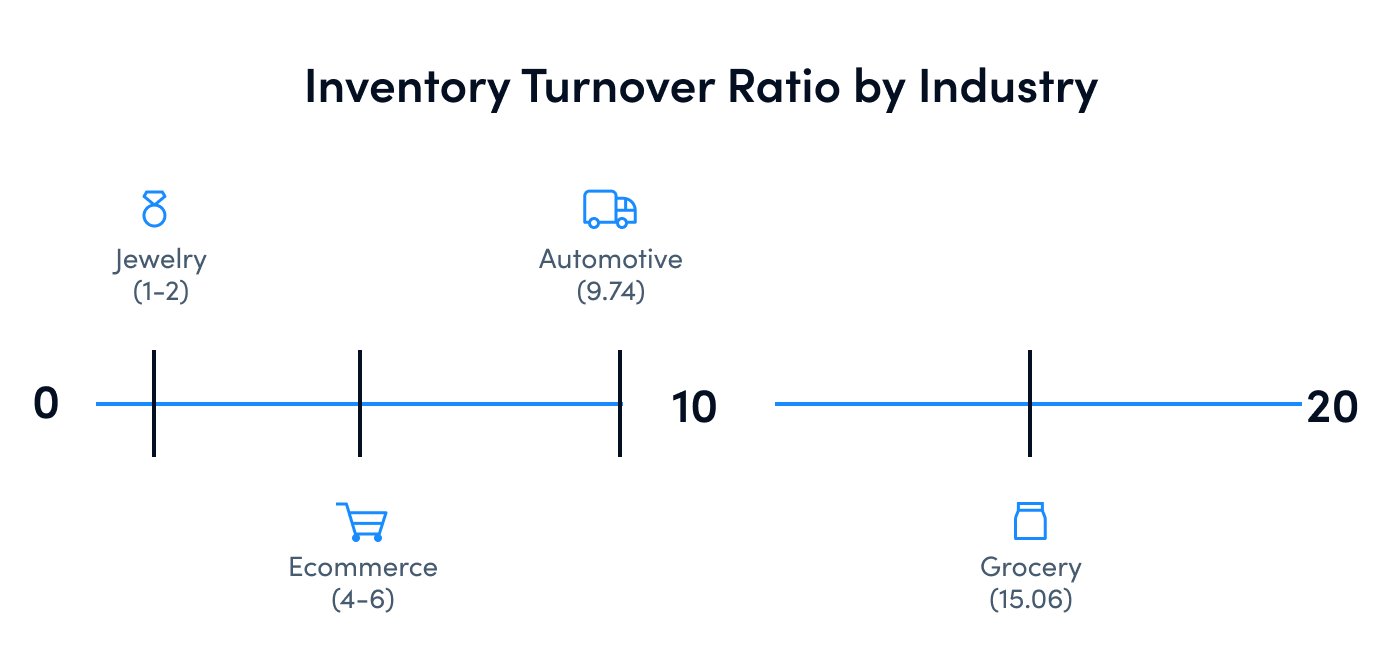

There is no one magic number for a healthy inventory turnover ratio. A “good” inventory turnover ratio varies based on your industry and unique business; high inventory turnover can be fine in some cases and harmful in others. That’s why you should benchmark your inventory turnover against businesses in your industry and optimize your inventory from there. An annual inventory turnover ratio between 4 to 6, for instance, is generally considered healthy for ecommerce businesses/retailers. But jewelers, who sell small items with high-profit margins, typically see low inventory turnover, in the 1 to 2 range.

Say you own a small graphic T-shirt business. An annual inventory turnover ratio of 4 would indicate that your stored inventory of T-shirts turns over (sells and is restocked) four times a year. This is a healthy ratio for an e-commerce business where products don’t expire and storage space is (hopefully) not too expensive. For your graphic tee business, an inventory ratio of 4 shows that you can easily introduce new products each season without spending too much time managing stock or too much money on storage costs from excess inventory.

Jewelers can sustain inventory turnover ratios lower than the 4 to 6 range because their profit margins and markups on individual items are typically much higher than that of a T-shirt business. Where a single T-shirt may yield a profit of $5, a necklace can bring in profits in the thousands.

Some businesses, such as food stores that sell items with short shelf lives, need a higher inventory turnover ratio—you don’t want milk sitting on your supermarket shelf for six months. Grocery stores typically see annual inventory turnover ratios just over 15 (as of 3 Q 2020).

Use Our Inventory Turnover Calculator

To calculate your inventory turnover ratio and ultimately find the perfect inventory balance, you will need three things—a given period of time to assess, your total cost of goods sold (COGS), and your average inventory.

1. Define the period of time you want to use.

For instance, you could calculate your inventory turnover ratio for the last quarter or the last month. Many e-commerce and product businesses find it helpful to calculate inventory turnover multiple times per year because the more frequently you check this metric, the better your odds are of spotting issues early (before they’ve gotten out of hand).

2. Calculate your COGS during that timeframe.

The “cost” part of COGS includes any cost you incur as a business to acquire, manufacture, or assemble your goods. For a graphic tee business, these costs might include the purchase price for fabric, manhours for sewing/assembling shirts, and ink for printing graphics onto each tee. Product businesses are required to report their COGS each year on their income statement, so you should already be tracking these expenses.

To calculate your COGS, take the cost of your beginning inventory (during your defined period of time), add raw material and/or inventory purchases, and then subtract your ending inventory.

Calculating your COGS can be complex and involves reviewing and analyzing financial statements, so if you have questions, don’t hesitate to reach out to your financial advisor or tax professional. Some inventory management software can also automatically calculate this for you.

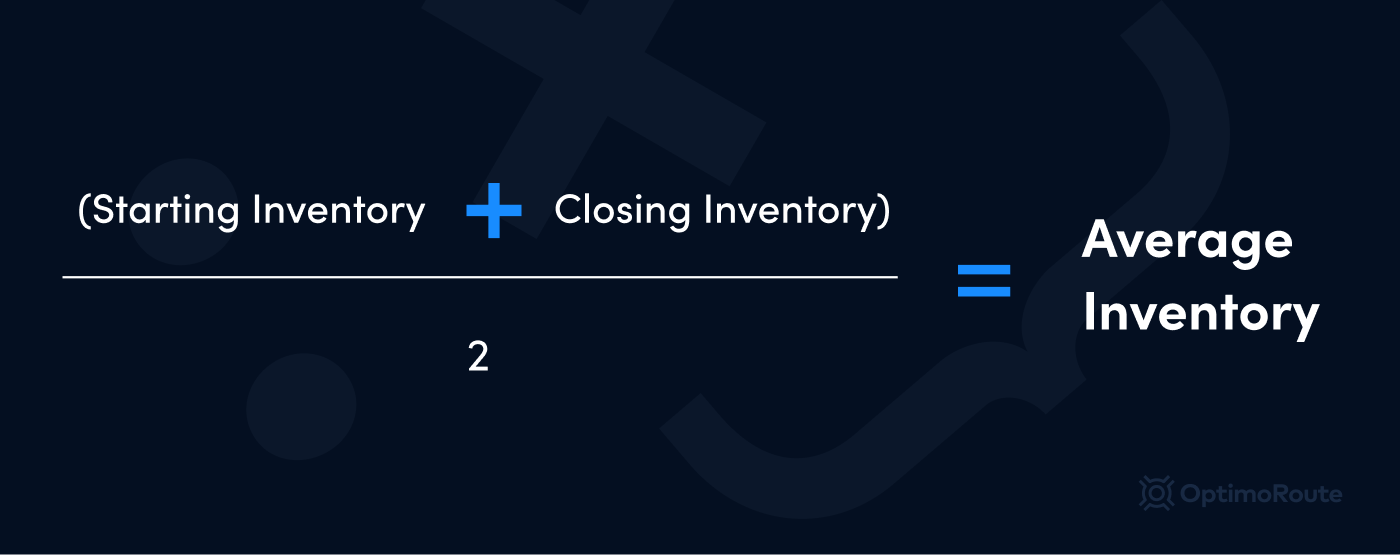

3. Next, you need to calculate your average inventory for the same given period of time.

Take the value of your inventory at the beginning of your defined time period, add it to the value of your inventory at the end of that time, and then divide that number by two.

So, to get your average inventory value for Q1, you would take the value of your inventory on January 1, add it to the total value of your inventory on March 31, and then divide that number by two.

Now that you’ve got your COGS and average inventory, you’re ready to calculate your inventory turnover ratio! Simply divide your COGS by your average inventory.

As an example, let’s say the COGS for your T-shirt business in Q1 was $10,000, and your average inventory was $7,500. To get your inventory turnover ratio for Q1, you would simply divide $10,000 by $7,500 to get 1.33. This would equate to an annual inventory turnover ratio of 5.33, which is within the industry average for e-commerce.

Reduce your operational costs by 30%

Increase delivery capacity by 43%

Plan 7x faster

6 Ways to Improve Your Inventory Turnover Ratio

Now that you understand what inventory turnover is and how to calculate your ratio, it’s time to arm yourself with tactics to improve your inventory turnover ratio.

Here are six ways to move your ratio in the right direction.

1. Improve your customer experience to boost sales

Customer experience is the key brand differentiator in today’s market (over both price and product). And research has shown that brands with a superior customer experience sustain revenue 5.7 times higher than that of their competitors with sub-par customer experience ratings. So, if you want to increase annual sales (and move more inventory), refining your customer experience is a good place to start.

A wealth of resources exist with tips and strategies for improving your customer experience, but at their core, each one is aimed at facilitating more enjoyable brand interactions between you and your consumers. Customer experience encompasses everything from your website design to social media interactions, so chances are if you dig deep enough, you’ll find at least one area of your customer experience that could use some improvements.

At OptimoRoute, we’ve helped hundreds of field service and e-commerce companies improve their customer experience by offering delivery transparency. Using OptimoRoute’s Realtime Order Tracking notifications feature, you can set up automatic delivery notifications with live tracking to go out to every customer when their order is on its way. This feature alone has helped brands reduce incoming customer service calls by as much as 70%.

2. Use just in time inventory management to increase inventory turnover

Just in time (JIT) is an inventory management method where goods are ordered, stored, assembled, and/or manufactured to fulfill orders at the last possible moment. The goal of the JIT method is to get orders to customers quickly while minimizing product holding costs. When you use the JIT method, which reduces the overall inventory in your warehouse at any given time and subsequently results in higher stock turnover, you don’t use safety stock.

JIT inventory management is inherently riskier than using safety stock because it increases the possibility of stockouts or late deliveries, and the greater in/outflow of inventory can make inventory control more difficult. Much of this risk can be mitigated with regular supply chain monitoring and proactive customer communications.

Many successful retailers that sell products with short shelf lives use the JIT method to minimize overstocking and reduce the amount of product they wind up throwing away because it expired while sitting on their warehouse or store shelf. Pharmacies, for instance, may use JIT inventory management to ensure the speedy delivery of medications to their customers while minimizing the number of pills that expire before purchase.

The JIT method isn’t just effective for retailers with time- and temperature-sensitive products, though. Apparel companies and other e-commerce brands can benefit from this, too. Some retailers are taking this a step further by doing away with inventory altogether. E-commerce platforms such as Society6 leverage print-on-demand models to offer independent artists a means of selling a vast array of products without needing any storage space at all.

3. Streamline warehousing and last mile delivery

Whether you use the JIT inventory management method or prefer to keep some safety stock on-hand, you absolutely must make sure your inventory flows quickly and efficiently from your storage facility to your customer. Just under half (49%) of consumers say they are more likely to buy a product online if same-day shipping is available. And more than a quarter of consumers will abandon their online purchase if same-day shipping isn’t available.

Connect your inventory management software to your route optimization software. OptimoRoute can be seamlessly connected via API integration. End-to-end visibility throughout your supply chain is essential for spotting roadblocks and fixing them in a timely manner.

4. Plan for seasonality

Many businesses see demand fluctuations around certain holidays. Flower shops like The Little Posy Co., for instance, may see as much as a 5x increase in order volume leading up to Valentine’s Day. While this means The Little Posy Co. will need to have a larger number of fresh flowers in stock at the beginning of February, they don’t need that same volume the rest of the year. Inventory levels can and should fluctuate in congruence with your demand to keep a healthy inventory turnover ratio throughout the year.

Use capacity planning to identify when you’ll need more inventory (and more personnel to manufacture or assemble products) and when you can reduce your supplies (and workforce). The Little Posy Co. not only regulates their flowers and staff numbers to accommodate seasonality, but they also shift their software plans (and thus their costs) too.

OptimoRoute makes it easy for you to shift your plan based on demand, so you’re never overpaying. Simply add or subtract the number of drivers using our sliding scale.

5. Boost sales by attracting more buyers

This one may seem obvious—a surefire way to improve your inventory turnover ratio is to increase demand for your product. But, it’s still worth mentioning because it is the foundation of any successful business. And while “make more sales” is a simple concept to understand, it’s a lot more challenging in practice.

Here are a few resources packed with proven marketing tactics to help you attract more buyers:

- Top 10 Most Effective Marketing Strategies

- How Influencers Can Boost Your Marketing ROI

- PPC Strategy Tips for a Strong Campaign

- 24 Free or Inexpensive Digital Marketing Tools to Drive Success in 2020

- 26 Inexpensive Customer Delight Ideas Worth Trying to Fuel Business Growth

Another way to attract more buyers, especially in a post-COVID world, is to offer your products faster or in a more convenient way than your competitors. Sephora recently partnered with Instacart to offer fast contactless delivery to their customers and remain competitive compared to other beauty stores offering curbside delivery. Make sure you offer competitive delivery options, especially if you sell any type of food item.

6. Reduce your risk of products being returned

Product returns negatively affect both your sales and your inventory. And while returns and exchanges will never completely go away for product businesses, that doesn’t mean you’re powerless to minimize their frequency.

Provide ample details about your products. Be honest in your product descriptions. Few things disappoint a consumer faster than getting a product that doesn’t look, feel, or function as it appeared to online. Make sure your product photos are well lit and provide an accurate representation of your goods. Consider adding short product videos (this is particularly beneficial for clothing, so shoppers can see how an article of clothing moves).

Make sure your goods don’t get broken in transit. The best way to avoid damage during last mile delivery is to use your own in-house delivery team that’s fully trained on how to handle your items. But if this isn’t possible, make sure your products are appropriately wrapped, insulated, and cushioned, so they can endure a bumpy ride.

Provide tracking notifications. Some products wind up going back to a warehouse because the buyer wasn’t home to accept the package. OptimoRoute customers use Realtime Order Tracking for up to the minute information regarding their package delivery. This kind of transparency and communication helps to ensure your customer actually gets their delivery (and it doesn’t wind up coming back to your facility). And you can easily provide this visibility through OptimoRoute.

Increase Inventory Turnover by Streamlining Last Mile Delivery

Improving your last mile delivery efficiency can boost your customer experience, improve supply chain logistics, attract more buyers, help you adapt to seasonality, and reduce the risk of products being returned. And if you already have a delivery team, start improving your efficiency today with OptimoRoute. We offer a 30-day free trial, so you can take our software for a spin with zero risk. Learn more about our advanced features.

Try OptimoRoute™ for Free

No installation or credit card required