A Guide to Backhauling in Logistics + Trucking

March 9, 2022 6 min read

According to recent data from Convoy, 29% of commercial trucks on the road are empty. This usually happens after a truck has delivered cargo to its final destination and the truck is on the return trip to its home base. The distance trucks drive empty on the road are referred to as “deadhead” or “empty” miles. Deadhead miles use more fuel, increase costs, and lower efficiency. Deadhead mileage is costly to business—but it doesn’t have to be. You can reduce your overall deadhead mileage with backhauling.

Jump to the section that interests you most:

- What Is Backhauling?

- 3 Benefits of Backhauling

- Internal vs. External Backhauling

- How to Optimize Your Backhauling Strategy With OptimoRoute

What Is Backhauling?

Backhauling is a logistics strategy that reduces deadhead miles to save money and increase efficiency. The process involves adding pickup stops into transportation and delivery routes. The pickup stops are strategically planned into the route based on how much cargo there is to pick up and which truck is available to pick it up. This keeps trucks full to avoid unnecessary deadhead mileage while also ensuring truckloads don’t exceed a truck’s payload capacity.

One example of backhauling can be seen in use by popular clothing retailers like H&M and ZARA, which use backhauling as a part of their reverse logistics practices. These retailers ship their clothing from the distribution center to each individual store in reusable tote boxes. Each store receives a shipment and unloads the products out of the boxes. Then they stack the boxes and set them aside. When the truck arrives with the next shipment, the store receives the new shipment and gives the truck driver the empty tote boxes from the previous delivery to return to the distribution center. The return trip to the distribution center is backhauling in action.

To use backhauling as a strategy within your own logistics, first look at your current planned routes to see exactly how much cargo is dropped off at each location. Then, calculate how much cargo the driver will need to pick up at each pickup location. You also need to assess the distance to each pickup location to determine which routes will place trucks in the area. Then match trucks to pickup locations and add the new stop to the route. But keep in mind that trucks can only pick up cargo if they have made enough deliveries for the new cargo to fit onto the truck.

3 Benefits of Backhauling

Backhauling helps you improve your bottom line by saving money and increasing efficiency. It also helps make your business more environmentally friendly to help win over customers.

Save money

Major clothing retailer Macy’s reduced operational costs by using backhauling to eliminate 11% of its empty miles. The retailer was able to do this because backhauling makes loading and transportation more efficient. This means that you only schedule the number of employees you need, which helps lower labor costs. Backhauling also helps you use your vehicles more efficiently, reducing wear and tear to extend the vehicle’s life.

Maximize operational efficiency

Backhauling improves overall efficiency through load planning, a process designed to improve the usage of trucks to maximize delivery capacity. It also improves the quality of service by allowing businesses to expand the availability of their services to provide immediate assistance to customers. For example, say an individual contractor in the trucking industry gets hired to transport a large shipment of product from Virginia to New York. Upon arriving in New York, the driver has to pick up one item to transport back to Virginia but will still have room in their vehicle for additional cargo. The trucker can advertise that they will be transporting items to Virginia and have space to transport extra items. This allows the driver to make more money by completing more jobs without requiring them to make additional trips or buy additional vehicles.

Improve sustainability

Sustainability is a driving factor in purchasing decisions for 60% of consumers, according to a recent study. Businesses that transport products, especially those in the transportation and trucking industry—which is responsible for 14% of the world’s greenhouse gas emissions— should improve the overall sustainability of their operations to help win over customers.

Green logistics strategies like backhauling are the best way to make your business environmentally friendly. That’s because backhauling reduces the amount of time vehicles spend empty on the road, thereby lowering greenhouse gas emissions, which are a major contributor to climate change.

Internal vs. External Backhauling

There are two types of backhauling: internal and external. In the next sections, we’ll explain what each type of backhauling is and why businesses use them.

Internal backhauling

Internal backhauling is the logistics process companies use to transport their own goods. One simple example of this is milk delivery services. The milkman drops off new milk, then picks up the empty milk bottles to backhaul to the base so they can be refilled. The process that H&M uses as part of its outbound logistics practices is also an example of internal backhauling.

External backhauling

External backhauling refers to shippers that transport third-party products, such as for-hire trucking companies. This is the primary type of backhauling that private fleets and reverse logistics companies conduct, as many large organizations outsource their shipping and transportation to lower costs. One example of this is semi-truck drivers who are contracted by companies to transport individual trailers. Another example is trucking companies that transport produce from a distribution center or farm to a supermarket.

How to Optimize Your Backhauling Strategy With OptimoRoute

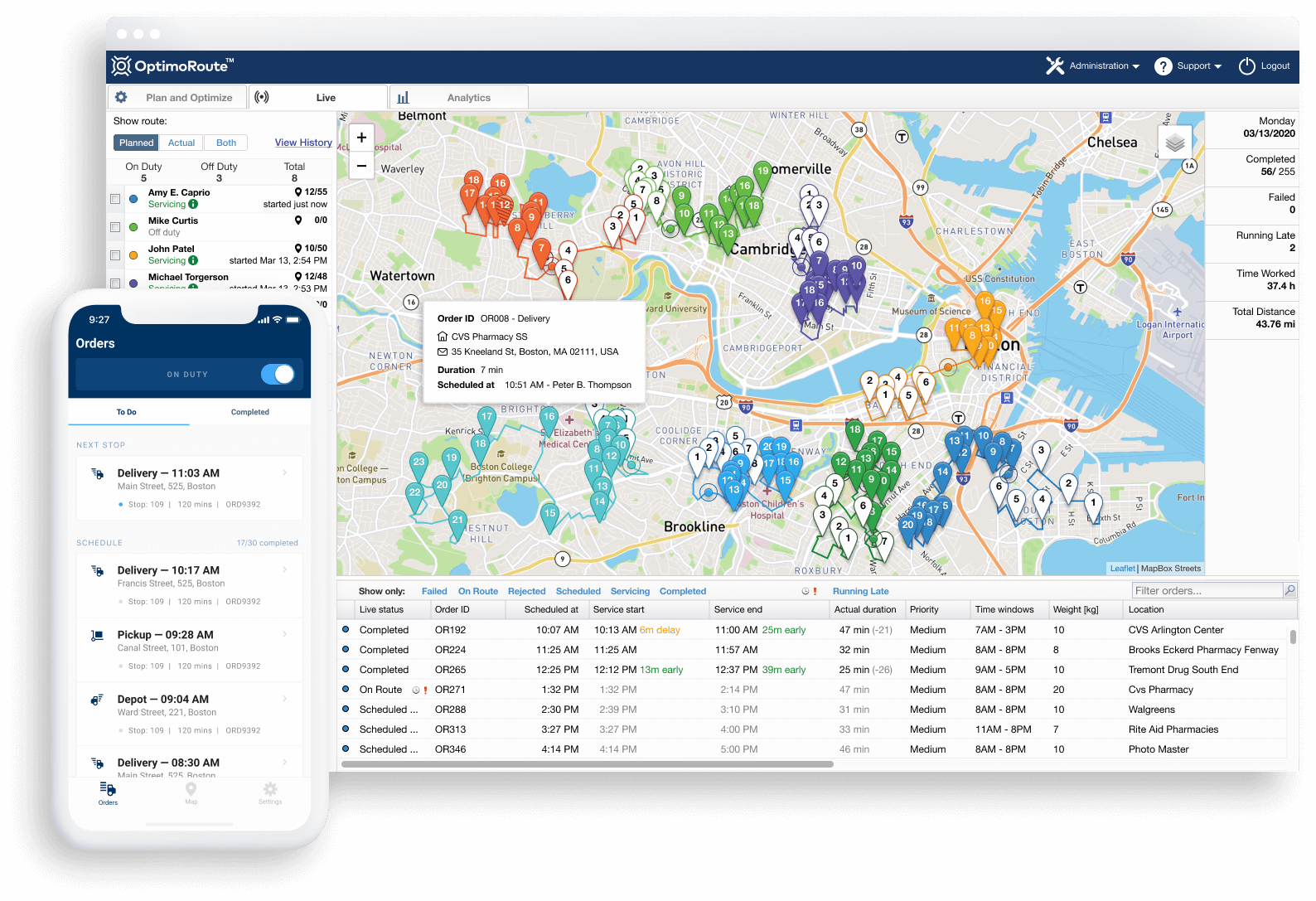

Backhauling is a valuable strategy for shipping and logistics businesses, but it is difficult to do manually. OptimoRoute is a logistics management system designed to help streamline backhauling by automating planning and scheduling tasks. The user-friendly interface makes it easy for end users to learn how to use the system’s planning and routing capabilities.

Automatically plan routes

You can use OptimoRoute to automate your planning. All you need to do is upload relevant information about your team and the delivery locations you need to create routes for. You can also include pickup locations, so the system knows to build a route designed to accommodate backhauling. Then you can click “plan routes,” and OptimoRoute will automatically build a route that is optimized for efficiency. The platform considers a variety of important factors, including which drivers are available, how many trucks are in your fleet, and the location and specifics of each stop on the route.

OptimoRoute’s weekly planning capability is able to create routes up to five weeks in advance—and allows you to make updates to preplanned routes as needed. The platform fully automates the routing process to save you time and help you manage your business more efficiently.

Account for vehicle size and capacity

Delivery trucks are limited by payload capacity as well as the number of boxes that can fit on the vehicle. OptimoRoute accounts for these factors when building routes to ensure that your vehicles aren’t overloaded. The platform lets you customize capacity constraints for your vehicles, so you don’t have to worry about calculating which orders can fit on which vehicles. This is a vital capability for backhauling, as you’ll need to know exactly how much space is available on your vehicles after each delivery in order to plan pickups.

Optimize driver scheduling

Build driver profiles within the system that include information such as the driver’s availability and their skillset. OptimoRoute uses this information when building routes to match drivers to delivery and pickup locations based on their qualifications and the demands of the order. This saves you time by streamlining scheduling. It also helps you to provide a higher level of customer service by ensuring complex routes are handled by qualified drivers.

OptimoRoute also schedules breaks to help ensure schedules comply with local labor laws while guaranteeing that deliveries and pickups still happen on time. Drivers can view scheduled routes on their cell phones via the mobile app, which shows turn-by-turn directions and shows updates to the route in real time to keep drivers and routers on the same page.

Multi-day long-haul routes

Long backhauling routes cover large areas and keep drivers on the road for several days at a time. To plan these multi-day long-haul routes, you need to account for the duration of the journey, including stops for the driver to stay overnight before they get back into the vehicle the next day. OptimoRoute facilitates this by allowing you to plan multi-stop routesto include mandatory breaks and overnight stays for drivers.

Pickup and delivery

You need to be able to make deliveries and complete pickups without returning to your base station in between for successful backhauling. OptimoRoute’s pickup and delivery function allows you to do this by distinguishing order types. This helps you to account for a vehicle’s load capacity, so you’ll know when a vehicle has the space for a pickup. This also helps you to know when a vehicle is full, so you don’t over-plan pickups.

Try our software free for 30 days to see how OptimoRoute can streamline backhauling!

Try OptimoRoute™ for Free

No installation or credit card required